“No offense, but plumbing [engineering] isn’t that hard.”

The above quote is what a colleague said to me during a leadership meeting. This phrase was uttered in response to my argument that the budget needed to be moved from HVAC design to plumbing design on a certain project due to the complexity of the plumbing design. But in essence, this leader said the quiet part out loud: MEP firms and engineers believe that plumbing design is “easy.” This even manifested itself on a recent plumbing engineering thread, where one plumbing design professional indicated to another that design of hot water return systems was “simple stuff” by just using rules-of-thumb for design.

The problem is that while many non-plumbing design professionals think plumbing engineering isn’t particularly difficult, real-world data and the latest developments say otherwise, indicating that plumbing design needs to move past “rules-of-thumb” engineering in order to meet 21st-century plumbing challenges.

Some of the “canaries in the coal mine” that are making it readily apparent that plumbing is not easy:

- Water conservation issues: Arizona has issued a moratorium on new home developments that rely on groundwater;

- Water quality: Flint, Michigan, water made thousands of people sick via lead, and is killing hundreds due to Legionella;

- Resiliency issues: The EPA estimates that the average home wastes about 10,000 gallons of water due to leaking pipes;

- Affordability: DigDeep released a report that estimated that more than 2.2 million Americans do not have running water or a working toilet at home, and this lack of access costs the U.S. $8.58 billion annually.

These are large-scale problems to which there is no easy answer. Additionally, new industry guidance, especially in regard to waterborne disease issues, is adding complexity to plumbing design:

- ASHRAE/ANSI Standard 188 came out in 2015 and changed the landscape of plumbing engineering risk, by elevating the necessity of risk management during plumbing design for buildings with populations that are immunocompromised. This document is 28 pages long;

- The National Academy of Science Engineering and Medicine released a 305-page consensus study report on the Management of Legionella in Water Supplies in 2019 that provides some plumbing design guidance.

- IAPMO and AWWA partnered to develop a Manual of Safe Closure and Reopening of Building Water Systems in 2022. This 45-page document details practical and actionable provisions for building owners and plumbing design professionals to take.

- The American Society of Plumbing Engineers (ASPE) Engineering Methodologies to Reduce the Risk of Legionella in Premise Plumbing Systems was published in early 2023 and provides 56 pages of specific and practical actions for plumbing design professionals to act on.

Just these four documents have more than 400 pages of information to solve one problem: Legionella. And we know Legionella is going to become a bigger issue in the near future as Markets and Markets forecasts that the Legionella testing market will increase from $296.0 million in 2022 to $439.0 million by 2027. We also know that Legionella lawsuits are on the rise — you only need to follow #legionella on Google alerts to see that the number of Legionella litigations is increasing. Even ASPE’s Legionella design guide had a section on legal considerations for plumbing design professionals.

Additionally, as I discussed in my last column, the licensing and credentialing needs for plumbing system design is increasing. When I earned my P.E. license in Arizona more than a decade ago, I took and passed the HVAC and Refrigeration Exam. I still vividly remember feeling unworthy on receiving my license. The reason for this was the HVAC and Refrigeration Exam I took only had one somewhat-plumbing-related question out of 80 (it was on fire systems). I felt that an exam that was supposed to gauge my professional knowledge to allow me to sign and seal plumbing contract documents didn’t capture any of it. This is in large part why, post-licensing, I decided to pursue and obtain ASPE’s CPD (Certified in Plumbing Design), the ASSE 6020 (Medical Gas System Inspector), and the ASSE 12080 (Legionella Water Safety and Management Personnel). I didn’t feel that my license indicated any kind of aptitude for the work I was doing. Hopefully, with the work that the ASPE Professional Engineers Working Group (PEWG) is developing, we will have a plumbing exam (under the mechanical discipline) soon.

Engineering firms need to take the approach to really develop deep technical expertise in plumbing. If not, the risks and consequences (risks to public safety and welfare as well as damage to an engineer’s and firm’s reputation and financial costs) are high.

There are numerous risks for engineering firms that do not encourage and develop their plumbing technical expertise. As I quoted in my last article, just like Peter Drucker said, “A brain surgeon is effective in that he is highly specialized in brain surgery, but by the same token couldn’t repair a damaged knee and would probably be helpless if confronted with a tropical parasite in the blood.” This is also true for mechanical engineers. As an ASPE PEWG letter indicates, “Today’s practice of engineering has become more difficult, if not impossible, for the typical Registered Engineer specializing in the Heating, Ventilating and Air Conditioning (HVAC) discipline. It is not practical or possible to maintain the necessary level of competency in the two distinct disciplines of plumbing and HVAC.” Engineering firms need to take the approach to really develop deep technical expertise in plumbing. If not, the risks and consequences (risks to public safety and welfare as well as damage to an engineer’s and firm’s reputation and financial costs) are high.

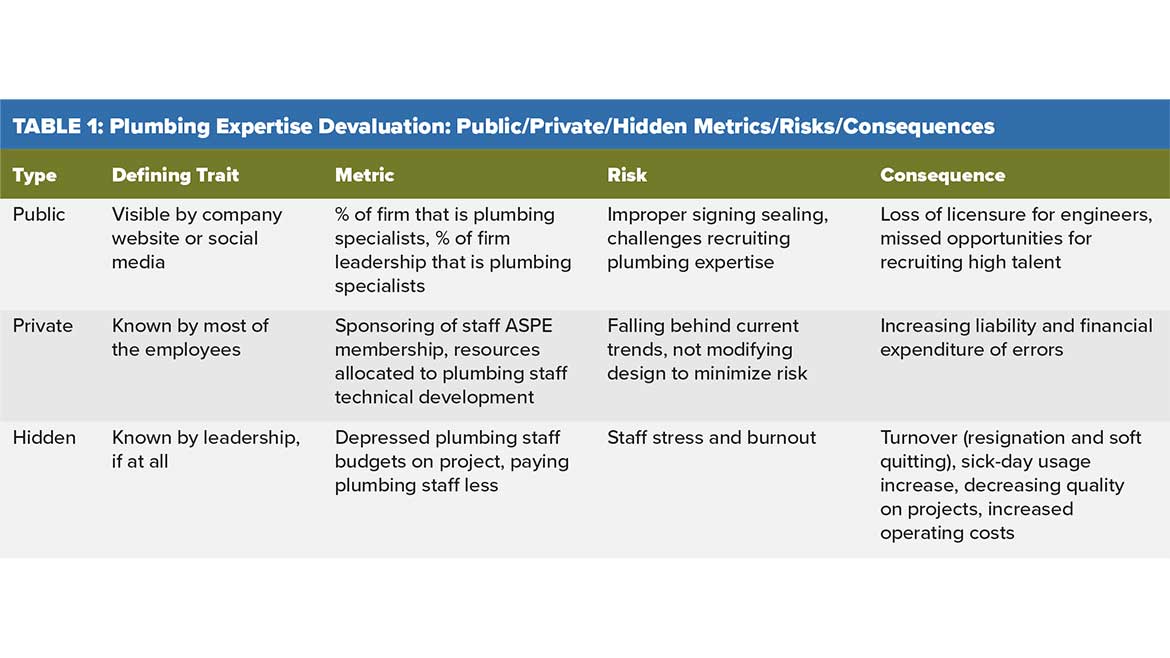

Metrics, risks and consequences: public, private and hidden

Engineering firms are already incurring a number of risks, and some of the consequences are beginning to materialize for many firms that do not have deep technical expertise in plumbing. One measure of technical depth is a “public metric.” Public metrics could include the percentage of plumbing design professionals an organization employs compared to other disciplines. If this number is small, then the plumbing expertise is typically low.

Another public metric is the number of principals a firm has who are plumbing design professionals. If firms don’t have owners with plumbing expertise, they likely do not have deep expertise in that realm. The risk then is that a mechanical engineer who does not have the requisite expertise in plumbing is signing and sealing plumbing contract documents. Another risk is that there will be a public perception that plumbing expertise is not worth the effort at this firm, which means that recruiting talented plumbing design professionals will become more difficult. The resulting consequence is not only that large-scale errors can occur on plumbing projects, but the engineer in charge risks losing their license.

I’ve often shared the story of how in the Phoenix metro area we have a special medical gas inspection form that requires an additional seal and signature beyond signing the medical gas (mechanical) drawings. I have witnessed mechanical (HVAC) engineers on many occasions refusing to sign and seal the special inspection form after signing and sealing the contract documents. This is still shocking to me as the special inspection is a verbatim reference to follow medical gas codes, which is also what the signed and sealed drawings should be doing. If an engineer is willing to sign contract documents but not the inspection form, this indicates to me that the threshold of “competence” should most certainly be questioned. It seems it is only a matter of time before an HVAC engineer working on a Phoenix-area project faces disciplinary action as a result of signing contract documents but not the inspection form. These errors can be mitigated by giving technically competent plumbing design professionals their place in the firm, not only at staff level but also in leadership.

However, a company’s private metrics are equally important. These private metrics are probably known by most of the staff but not broadcast via company websites or social media. This manifests itself as sponsoring employees to be members in the American Society of Plumbing Engineers and giving staff resources (time and/or money) to attend plumbing technical training. If plumbing expertise is not valued then plumbing design professionals probably will not be afforded these opportunities, and the firm will not learn about the latest trends or requirements. The risk here is great: the engineering firm will fall behind, and by not following the latest standard (such as ASHRAE/ANSI 188) or guidance (ASPE Engineering Methodologies), the liability and financial risk increases, and greatly. Especially as plumbing is quickly becoming more and more complex, the consequences are becoming even more dire: monetary damages that cripple the firm.

For example, let’s say your firm had an error on a project that results in a case of Legionnaire’s disease. This results in a civil trial with a jury (i.e layperson, with council on both sides likely excluding design professionals, not wishing their enhanced knowledge of potentially steer a jury to its verdict). The court hears the plaintiff’s argument, which goes like this:

“Engineering firm XYZ did not follow any of the Legionella codes and guidance documents. In fact, when we subpoenaed the firm for their documents, we could not find a single reference to any of the Legionella documents on their servers. Not only that, but the firm had no record of attending any of hundreds of available Legionella classes. They did not have the professional expertise to do this job and as a result endangered everyone, including our client. If they were competent, why did they not have the documents, nor take the time to develop the expertise?”

Then imagine the defending lawyer trying to convince a jury made up of layperson that not having the latest educational material and training wasn’t detrimental to the performance of the firm. Difficult is a gross understatement.

Finally, there are also likely hidden metrics in the engineering firm that signify a low value of plumbing. Hidden metrics may only be known by leadership of a firm, if at all, as they require more “digging” to determine. Hidden metrics may take the form of depressed project budgets for plumbing compared to other disciplines and/or paying plumbing design professionals less than their HVAC or electrical peers.

The hidden risk here is that plumbing engineers are then overworked due to too high of a project workload (due to low budget assignment or having to work more efficiently than other disciplines). All of this can lead to stress and burnout. Combine this with negative public metrics and feelings of a lack of appreciation will occur. These hidden consequences are often slow moving, but incredibly painful: lowered quality on projects as staff are rushing more, leading to more change orders and payouts; more staff leave, as increasing stress levels leads to health deterioration; and, finally, increased staff turnover (either by resignation or quiet-quitting).

In some ways this last item is already occurring in the industry: witness the number of senior plumbing design professionals leaving engineering firms to work for manufacturers or contractors directly. The consequence for the firm is the same, however: higher operating costs due to total hiring costs (which include recruiting, on-boarding, and general training).

Solutions and conclusions

As we clearly show, engineering firms that have the attitude that “plumbing is easy” are going to put themselves in precarious positions. A number of actions need to be taken to mitigate this risk. The first step is to eliminate the thought that “plumbing is easy” from the organization’s lexicon. As Gandhi famously said, “Your beliefs become your thoughts. Your thoughts become your words. Your words become your actions. Your actions become your habits. Your habits become your values. Your values become your destiny.” Organizational policies that discipline this “professional harassment” are critical to creating a culture that values plumbing specialization.

While engineering firms can take proactive measures to prevent the devaluation of plumbing technical expertise, there remains a need for some kind of industry accountability mechanism. I imagine this will likely be some combination of plural sector collaboration with industry media, working alongside a professional survey firm. We need some kind of industry survey of “The Best MEP Firms for Plumbing Design Professionals to Work For.” Points for consideration for MEP firms in “making the cut” could include:

- Greater than 20% of staff is plumbing-focused (by proof of staff title);

- Greater than 15% of overall leadership is plumbing-focused;

- Greater than 10% of senior leadership team came from the plumbing discipline;

- Sponsoring of all plumbing staff for ASPE membership;

- Sponsoring 100% of staff to attend four plumbing training events per year;

- Involvement in plumbing standards and code development;

- Plumbing staff turnover rate below 5%;

(Feel free to argue with me about the percentages and points.)

Another necessary step would be conducting an industry salary survey (including benefits and bonuses) for plumbing design professionals and comparing it to HVAC design professionals. This is likely easier now than ever, as many professionals are sharing this data anonymously with websites like Glassdoor, LinkedIn and Salary.com. But monetary compensation is so important to day-to-day that it is vital for plumbing design professionals to be able to see where they stand. ASME had a similar salary survey recently done for mechanical engineers in general. Providing plumbing design professionals with the data on compensation better allows these specialists to better map out careers and achieve personal goals.

In the 21st century, we face a number of plumbing challenges. In order to overcome these challenges we will need to drive toward expertise and specialization in plumbing systems. Licensing and certifications will likely play a lead role in developing this expertise. In order to promote this shift in thinking, it will be necessary to change the mentality toward plumbing design professionals and make sure the incentives align with this mentality shift. Some of these mentality shifts will be internal while others will be external. It is the external threats of legal entanglements and unnecessarily increasing cost of business that present the biggest threat. Engineering leaders who don’t position their firms strongly pose the biggest risk to their business, with the margins for error becoming smaller than ever. However, this also means that the opportunity for design firms is also greater than ever. The engineering firms that grab these available reins will be in a great position for future success.