There is no doubt that issues with natural resources and conservation of energy will continue to make daily news headlines. The concerns around exploiting our depletable resources and sensitivity on the battered environment have led society to find alternative and better ways to use and manage the energy that is available to us, principally in the use of renewable resources such as absorbing and storing solar energy.

Fortunately, the advances in new technologies allow new ways to maximize the use of renewable resources, incorporating more efficient materials and manufacturing processes for reliable certified products at a large scale, and making them affordable for all consumers. In recent years, the development of more efficient and complete systems has expanded widely in the plumbing industry, commercially and in the common household. These advances in the solar industry are the basis for more reliable energy production for our future, with a minimal carbon footprint for all.

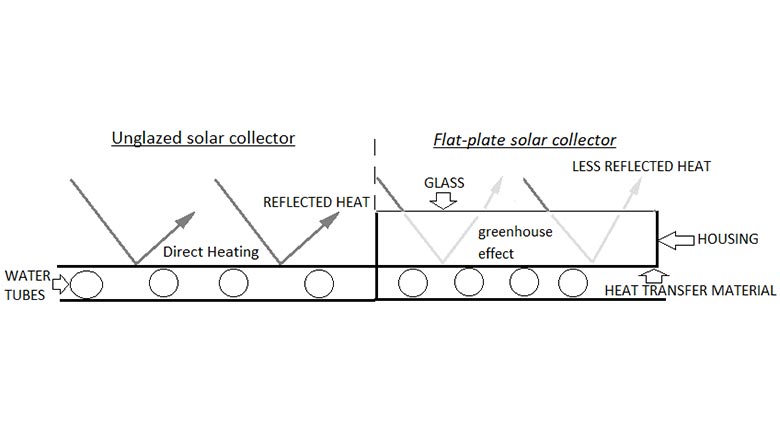

Solar thermal technology refers to the absorption of heat from the sun and transmitting this energy to useful applications, such as building heat or water heating. Solar heating varies in capacities and efficiencies, from simple components and materials to complex arrays of solar collectors and control systems. The use and selection of these systems depends on various factors, including the location of the solar panels and their design. Solar water heating system technologies use different types of solar collectors, such as unglazed solar, flat-plate and evacuated tube.

Unglazed solar collectors are an economical and simple way of heating water by absorbing the heat with a conductive material surface exposed to the sun. The heating transfer material may be in the form of plastic tubes that are exposed to the environment. Regular applications of unglazed collectors are for relatively low temperatures, 80° to 100° F, for small storage capacities and are often used as secondary sources of heating to a traditional water heater in solar pool heating systems. For simple water circulating, a thermal symphonic flow can be achieved with an exchange of temperatures and water densities, without the need of a pumping system.

Flat-plate solar collectors are usually constructed with copper tubing within a protective housing of a heat-absorbing material. Clear glass or glazing is used for absorbing solar heat in a more efficient way. This enclosure allows the trapping of heat, creating a greenhouse effect by absorbing the heat by means of convection into the medium surrounding the water heating tubes instead of being reflected back to the environment. Flat-plate collectors are often used to preheat supply hot water and complement water boilers, between 80° to 180° F, in a wider range of temperatures than the unglazed collectors. Most of these collectors are active systems, which include circulation pumps and controls. In some circulation systems, an indirect flow is used with approved food-grade fluid in the solar collector loop circulating between the solar collector and a heat exchanger.

Figure 1: Unglazed versus flat-plate solar collectors. Diagram shows comparison between two common solar heat collectors with direct heating and encasing.

Figure 1: Unglazed versus flat-plate solar collectors. Diagram shows comparison between two common solar heat collectors with direct heating and encasing.

Evacuated tube solar collectors are clear glass or plastic tubes with a vacuum seal that house copper tubes for heating water or other fluids. The tubes expose a larger surface area to the sun, at many different angles, collecting more of the sun’s energy and producing higher temperatures than flat-plate collectors. The tubes’ vacuum space traps the heat, preventing it from being reflected to the environment. Evacuated tube solar collectors’ heating capacity is used for readily very hot water in industrial applications, some above 400o F.

Product certification

Solar collectors’ specifications are established in U.S. industry standard SRCC-100. In this standard, “the minimum requirements are established for the product's durability, constructions, product performance criteria and a procedure for thermal energy performance.” Test methods referenced in the standard SRCC-100 are mandated in accordance with the reference standard ISO 9806.

Solar water heating system specifications are covered in standard SRCC-300. This standard applies to “solar thermal systems that provide hot water, space heating, cooling and pool heating for residential, commercial, and industrial applications.”

SRCC-400 is the standard that “sets minimum requirements for the performance, design, and installation of solar energy systems for heating water used within pools, wading pools and spas. This standard will apply to both residential and commercial systems, both direct and indirect systems.”

Product certification of complete solar systems requires the certification of individual components, such as plumbing fixture fittings, waste fittings, solvent cement, pipe, suction fittings, pumps and electronic controls. Certification of components is covered when complying within their respective IAPMO, ASME, ASTM and UL standards and their applicable plumbing and electrical local code requirements.

ArtistGNDphotography/E+ via Getty Images.

ArtistGNDphotography/E+ via Getty Images.

Solar collector thermal energy ratings are a simple way for consumers to compare the expected product performance and the energy savings. The process for rating a solar collector or system starts by testing and certifying the solar collected individually or the complete system to the SRCC-100 or SRCC-300 standard, respectively. Energy efficiency testing is completed through exposure to the actual sunlight or simulated sunlight in a controlled environment. The performance efficiency is calculated using test data for a collector, or system, along with information on the product’s design and installation guidelines per the ISO 9806 procedures. The thermal energy efficiency ratings are calculated using test data, coefficients for efficiency equations at the normal incident angle, or incident angle modifiers (IAMs). Thermal energy production ratings are recognized by the U.S. states and federal level in the tax code and are promoted as a form of rebates or incentives. In the state of California, the collector or system energy production ratings information is submitted directly by the certification body IAPMO to the California Energy Commission database for publishing on the product information website.

Product certification of complete solar systems requires the certification of individual components, such as plumbing fixture fittings, waste fittings, solvent cement, pipe, suction fittings, pumps and electronic controls.

Certified Product Markings

Certified solar products comply fully with the corresponding performance standard(s) and the Uniform Solar, Hydronics and Geothermal Code (USHGC) or the Uniform Solar Energy and Hydronics Code (USEC). The USHGC sets additional requirements for the product design, alteration, repair and installation of such products.

Code requirements also include backflow protection against back siphonage and contamination of the potable water. Another important aspect of the systems is the use of heat exchangers with an approved fluid medium transferring heat to the hot water supply. Double wall heat exchangers are designed in which a single failure of any fluid barrier will not cause a cross-connection or permit back siphonage of a heat transfer fluid into the potable water system.

Solar systems are in demand as a more affordable way of producing and storing solar energy for hot water supply. A USEC or USHGC certification is imperative for ensuring and maintaining the quality and performance of these solar products. Product certification information allows the quantification of solar energy production through the system’s ratings, which are supported and motivated by government programs with incentives and rebates. Government-supported investment programs and sensitivity to impacting the environment are keen for the public for choosing solar systems as a reliable alternative for water heating.