We have used our experience to design and produce a penetration that could truly be classified as waterproof and pass ASTM E-814 fire tests.

There are two issues associated with leakage from ProSet penetrations previously thought to be waterproof. The first is leakage between the pipe and the penetration due to human caulking error in the pipe installation process.

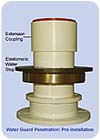

The other issue is associated with the expansion and contraction of rigid plastic water stops and the contraction of the concrete while curing. The combination of these forces can cause cracking around the water stop and the concrete. This leads to leakage on the outside of the sleeve through the concrete floor.

In addition to the sleeve extension, the Water Guard has a large, flexible Elastomeric water stop ring around the middle of the sleeve that adjusts to the expansion and contraction of the sleeve and the contraction of the concrete. This prevents the cracking that can occur with a rigid water stop.

Water Guard, used with a wide variety of piping, has been successfully water tested with a 36" head of water for 72 hours with no leaks.