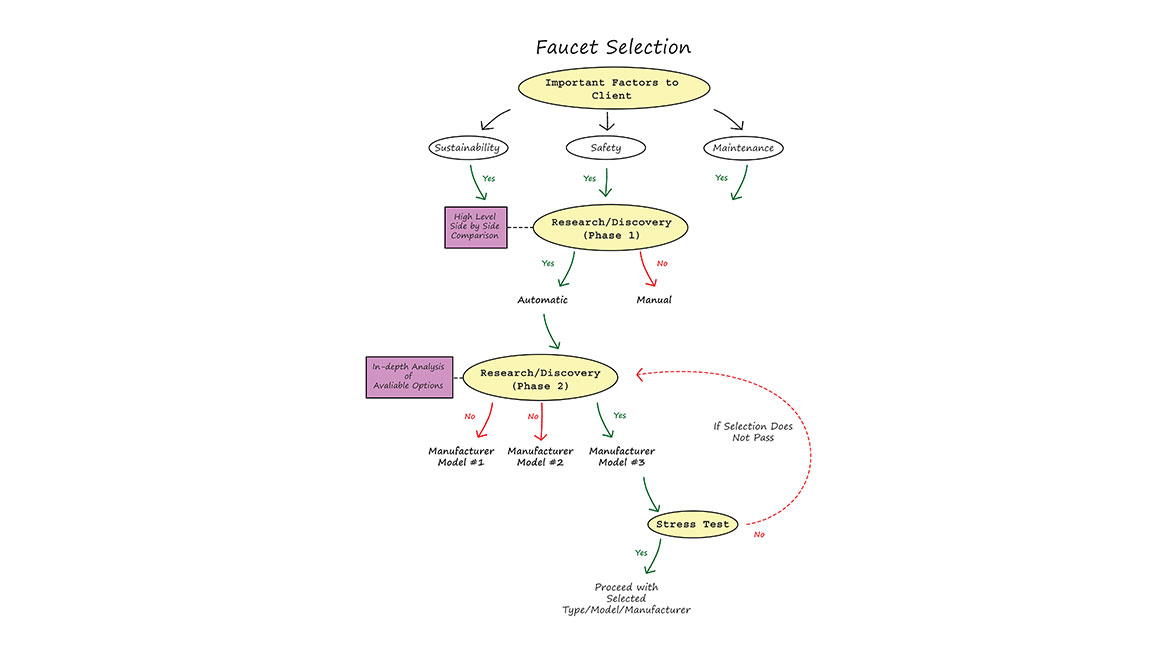

I highlighted the selection process diagram during my January column titled, “The process behind seamless water heater selection.” I received feedback from a reader interested in whether I could use the same process for a simple faucet selection using the previous four factors — ‘important factors to client, research/discovery (Phase 1), research/discovery (Phase 2), and stress test.” My first reaction is “It is just faucet.” I quickly realized that my default response goes against what I have been trying to change in our industry – the oversimplification of plumbing design that results in most people observing that it is “Just Plumbing.” So, let us dive into it and use the process for selecting faucets.

Note that this column does not address the findings in detail since there are many resources available when comparing faucet types. The intent instead is to highlight the process steps.

FIGURE 1

Image courtesy of Gabrielle Miranda

1. Important factors to the client

In this example, the clients’ importance factors in the selection of a faucet are sustainability, maintenance and safety. Assume that this project is for new building construction.

Note that it is important to know if the building is new or existing as this will impact the Research and Discovery phases.

2. Research and discovery — phase 1

Research the pros and cons of using manual vs. hands-free faucet. Though this might seem quite simple on the surface, it is still important to go through this process. The approach gives you an opportunity to get more familiar with the new faucet types, updated codes and standards that are out there. Below are sample research and discovery outcomes.

- Hands-free automatic fixtures create a safer and more sanitary environment. Since the surfaces of fixtures are being touched less, there is much less risk due to cross contamination. Less contact with surfaces also translates to reduced need for cleaning.

- The hands-free fixtures provide effortless operation since users do not have to reach beyond the fixture to operate the faucet or flush valves. This improved convenience and reduced time of fixture operation encourage people to develop better, more consistent practices for hand washing with reduced risk of contamination after washing hands.

Though hands-free faucets may require less cleaning, there is maintenance associated with these products, such as replacing batteries if batteries are used.

3. Research and discovery — phase 2

At this point, hands-free is the faucet of choice, but we also want to examine different features, options and power sources. The different power sources used in hands-free fixtures are hard-wired, battery, solar and turbine. In the importance factors phase, one cons identified with the hands-free fixtures is the increased maintenance due to replacing batteries.

Hardwire is the first choice for power source. The second choice is the use of hybrid power such as solar and turbines. In addition to the power source, other hands-free features include an auto purge where the faucet can be programmed to periodically operate for a preset period to limit the amount of time water is dormant within the domestic water system. This allows the domestic water system to be flushed out automatically even when there are no facility personnel in the building, reducing the potential for stagnation and better protecting the visitors and the personnel within the building.

Information such as total activation, hours of operation and battery life can aid maintenance personnel in understanding usage patterns and when preventative maintenance is needed. This allows facilities to remain a step ahead of potential issues and limit emergency maintenance.

Some faucets are also capable of collecting data. Information such as total activation, hours of operation and battery life can aid maintenance personnel in understanding usage patterns and when preventative maintenance is needed. This allows facilities to remain a step ahead of potential issues and limit emergency maintenance. Smart maintenance can be scheduled off hours and limit disruption to other building operations. This is especially critical in mission-critical facilities such as hospitals where access may be restricted.

4. Stress test

This is the last chance to challenge the outcomes of the abovementioned research and discovery phases, challenging the concept's validity, feasibility, and constructability.

For this example, this is where I recommend the engineer or designer present to the client the proposed fixtures. Why wait till after the stress test to present to client? After completing steps 1 through 3, you have become well-informed and can present the proposed choice with confidence.

The example above used the same process I discussed previously in a different scenario. Note the added benefits of this process are that if the team desires to Value Engineer (VE) the faucet direction, you have already completed the research and can intelligently speak to any differences in the productions, both from the perspective of the manufacturer and the owner.