As the world seeks more sustainable and electrified solutions for common construction and engineering challenges, the ways in which large buildings deliver hot water to tenants are worth examination.

Heating and delivering hot water throughout multi-residential and commercial buildings can be challenging, and traditional ways of designing hot water delivery leave much room for improvement.

Traditional hot water systems heat water with a central heater and are usually located in the basement, circulating water throughout the building as needed. Unused water is then returned to the water heater and reheated to keep it hot enough for use by building occupants.

These “recirculation systems” require that water heater temperatures heat water to at least 5° above the desired temperature coming out of the faucet, given water loses heat as it recirculates through pipes. Not only does this overheating waste energy, reduce boiler efficiency and increase water heating costs, but the water often still arrives at different units in buildings at inconsistent temperatures, making it challenging for building operators to properly balance their systems. Additionally, water and energy submetering, which allows building owners and tenants to track individual usage for each building unit, is difficult and costly with recirculation systems in place since water flows in two directions.

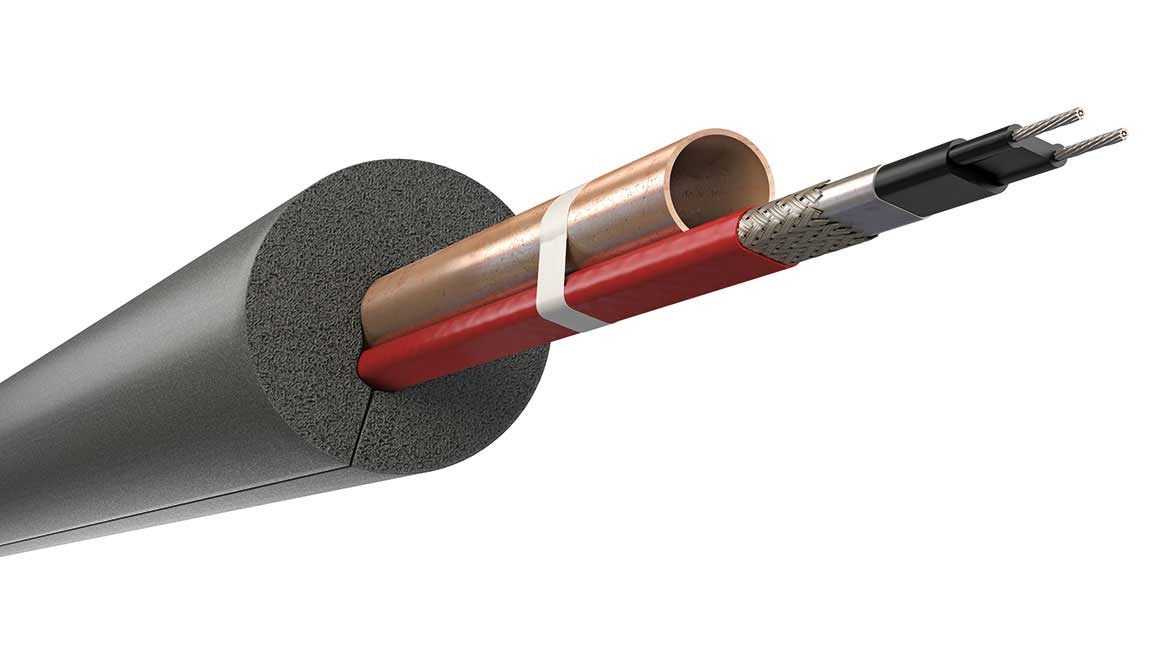

nVent's self-regulating trace heating cables maintain water temperatures in a building's hot water distribution network. Installed underneath the thermal insulation, they automatically compensate for pipe heat losses where they occur and provide an energy efficient solution.

One method seeing strong adoption is the use of agency-approved (such as UL) specialized electric heat-trace systems to create a single-directional hot water delivery system. This technology can be used in conjunction with a traditional recirculation main, or as a standalone solution that can provide a lower installment cost, energy and water efficiency, improved water quality and customer satisfaction. These systems are successfully being deployed worldwide in multifamily, condominium and residential housing, as well as in hotels, offices, hospitals, schools, mixed-use and other commercial and institutional buildings.

These single-pipe heat-trace systems are constructed using sensors at the site of water heaters, an electronic controller to control water temperature as it flows throughout the building, connection kits and insulation and self-regulating heating cables on water pipes to maintain a desired water temperature to points of use. These systems can deliver nearly instant hot water as soon as building occupants turn on the tap, all but eliminating wasted water used while people wait for the water to heat up.

There are major benefits to single-pipe heat-traced hot water distribution systems:

1. Energy efficiency: Single-pipe, heat-traced systems have third-party proven energy savings of up to 16% versus recirculation systems and may be eligible for LEED points for Energy Savings and Innovation in Design. Electrification, sustainability and decarbonization all are growing trends. As codes and standards evolve away from fossil fuel consumption, alternative solutions for hot water generation, such as electric heat pumps with electric heat-traced distribution mains and branches, are becoming increasingly common.

2. Design efficiency: Single-pipe heat-traced hot water delivery systems are simple to design and install. Eliminating the return lines, pumps and valves that come with traditional recirculating systems simplifies design and saves valuable space in buildings. Easy-to-program controllers monitor the boiler and pipe temperatures and power the cable only as needed to maintain desired water temperatures. These systems are available in both 120V and 208-240V options and approved for use on both plastic and metal pipes. Easy-to-install connection systems have been developed for use with self-regulating heating cables, which can reduce installation time and potentially lower total installed system cost. Approved traditional heat shrink kits also may be used. These systems require minimal power and can be easily and economically incorporated into the electrical infrastructure of commercial and residential buildings as they often require only a 10 Amp 120V breaker.

This technology can be used in conjunction with a traditional recirculation main, or as a standalone solution that can provide a lower installment cost, energy and water efficiency, improved water quality and customer satisfaction. These systems are successfully being deployed worldwide in multifamily, condominium and residential housing, as well as in hotels, offices, hospitals, schools, mixed use and other commercial and institutional buildings.

3. Easier and more cost-effective submetering: Submetering of both energy and water usage is becoming increasingly common and required by local codes. These systems make submetering easier and less expensive to implement since the system is one-way. Accurate and efficient submetering makes it easier to track and bill for individual unit’s energy and water consumption, which further encourages conservation.

4. Legionella control: Electric heat-traced single-pipe hot water delivery systems can effectively maintain the temperatures required by your building services’ Legionella risk management program. For additional information on the proper design, installation, operation, maintenance and management of your building water systems to reduce the risk of Legionella Disease, see ASHRAE 188-2023 and CIBSE TM13: 2013.

5. Convenience and end-user satisfaction: By tracing the hot water lines to point of use, you minimize the wait for hot water to arrive to your sink or shower. This not only conserves water and energy and reduces costly input to municipal sewers, but also creates a more positive day-to-day experience for building occupants and enhances your building’s reputation.

As the world becomes more sustainable and electrified, architects, engineers and contractors are re-examining their approach to many common systems. Single-pipe, heat-traced hot water distribution systems are becoming a part of that discussion and will be an important technology for a more sustainable future.