From the street, Bayview Tower in downtown Seattle looks like many other 1970s-era affordable housing apartments found across the U.S. This 13-story, 100-apartment property, run by the Seattle Housing Authority (SHA), provides an affordable senior-housing option to Seattle’s financially at-risk community. But, around the back of the building exists a domestic hot water (DHW) system, which is anything but 1970s. In 2021, one of the first packaged CO2 heat pump water heating (HPWH) systems for domestic water in the country was installed in Bayview Tower. Designed by Ecotope and funded by a collaboration between SHA, Seattle Office of Housing (SOH), and the Bonneville Power Administration (BPA), this project serves as a proving ground for a new class of fully packaged domestic HPWH systems. These systems will be an essential technology for building decarbonization and are a technology that can bring energy equity to underserved buildings and communities.

This article details the evolution of the project, the installation and performance of the system, the impact proper systems packaging and factory installation of system components had on the successful installation and operation of the system, and much more. All key stakeholders agreed pre-packaging and testing increased the comfort level with this new concept, thereby making the energy efficiency and decarbonization benefits repeatable.

The project

Delivering energy equity solutions to buildings, like Bayview Tower, has been a challenge for the past 20 years. According to the U.S. Department of Energy (DOE), property owners of low-income housing properties are challenged in prioritizing investments in energy efficiency, which can result in improved tenant comfort and lower energy bills with decarbonization. After all, decarbonization solutions can come at a higher first cost and can be difficult to adopt in low-income housing buildings. In addition to the always tight budgets of these buildings, continuous occupancy demands that DHW remain available throughout any project upgrade or system changeover. The original hot water system consisted of six electric resistance boilers. Bayview Tower consumed 230,000 kWh of energy annually. The SHA wanted to upgrade its domestic hot water system with a more efficient and environmentally sustainable solution. The installed CO2 HPWH solution is on track to reduce energy consumption to 95,000 kWh of energy a year — a nearly threefold reduction of energy.

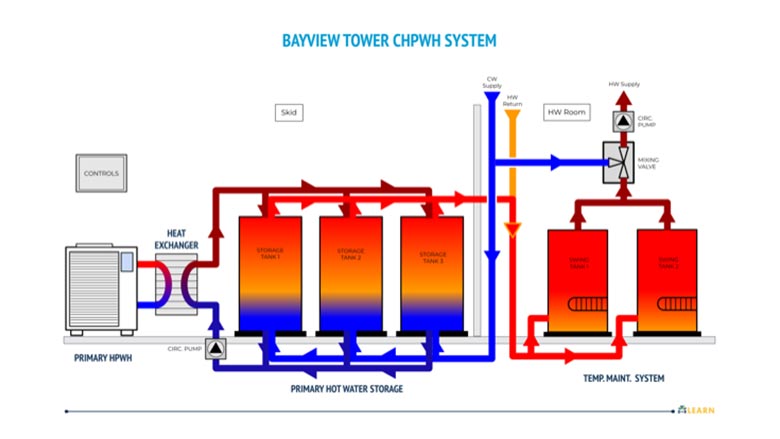

Displacing the senior housing population in the building for any period of time was not a reasonable option. The retrofit nature of the project and the need for a continuous water supply drove the team to a solution that could come to the job site pre-packaged and ready to operate. Four of the six electric resistance boilers were repurposed as “swing tanks” to provide temperature maintenance on the recirculation system during periods of low to no hot water draw, like overnight, and to deliver backup water heating capability when the new HPWH system is offline requiring maintenance.

The technology

The Origin system is the brainchild of Ecotope, brought to life by Steffes Corp. and powered by a Mitsubishi QAHV CO2 heat pump. All three companies are members of the Advanced Water Heating Initiative, which has been actively working to transform the water heating market to heat pump technology. Ecotope, led by Jon Heller, is a mission-driven engineering and research firm focused on leading the building sector toward a more efficient, low-carbon future. The team’s goal was to slash energy usage in the building while delivering consistent hot water supply during all demand conditions.

This project required seamless integration to the building’s existing DHW system. In addition to mechanical integration and ongoing availability of DHW during construction, proper integration with the building’s electrical system was required to assure the necessary power is available to operate the new HPWH system.

The SHA required automatic controls to operate continuously without operator intervention due to lack of on-site building operations staff. This is not an uncommon situation with low-income properties across the country. In addition, it was important to BPA that the Steffes Origin system be equipped with demand-response capabilities consistent with the guidelines recommended by the Advanced Water Heating Initiative. The Origin system was pre-wired with automatic controls that include an EcoPort (CTA-2045), enabling the desired demand response and M&V monitoring by Ecotope to validate assumptions and document performance.

The Origin system was constructed in Steffes’ manufacturing facility in Dickinson, North Dakota. The complete assembly, coordination, and interconnection of both the mechanical and electrical parts of the system were factory-tested, which included leak testing of the piping and verification of all electrical connections. The system arrived on the job site as a single package, and the installation team went to work connecting three water pipes, providing electrical power at a single point and starting up the system to deliver an economic and energy efficient supply of domestic hot water. The factory tests gave job site installers confidence the system they were installing had been checked and was ready to operate, thereby reducing their project risk associated with this new type of system.

The results

The project team was targeting a 65% reduction of energy usage while delivering consistent hot water supply during all demand conditions. Initial results have shown the Origin system delivered that energy reduction goal over the conventional electric resistance hot water tanks in the first six months of winter-time operation.

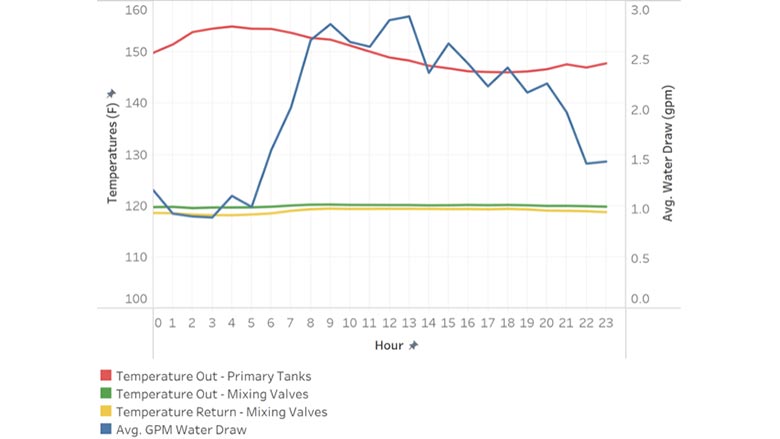

The system began operating in October 2021, and data is currently available for the fall period of October 2021 through early December 2021. During that time, the system has reported consistent water temperature delivery within 2°F of the system’s 120° set point. This early result confirms the system’s ability to meet demand during the relatively cool fall season.

Observed system run times are also consistent with expectations. The HPWH system operates during the daytime hours, when water draws are occurring. At nighttime, when no water draws are happening, the repurposed electric water heaters operate minimally to offset heat loss in distribution piping. Keeping the building supply loop at temperature allows hot water to be available without excessive wait times at remote building fixtures and avoids needless extra water use and energy waste from running water for long periods before it gets hot.

Most importantly, the energy-saving performance of the HPWH system has been verified. During December 2021, the new system experienced an unexpected shutdown of a circulation pump. While the issue was being diagnosed and a replacement pump was being obtained and installed, the system automatically began to operate on its backup supply of commercial electric resistance water heaters. Logging of system energy usage continued, and this provided approximately a month of data to directly compare against the HPWH system operating data.

The results were encouraging. The system operating under HPWH generation used 300 kWh per day less than the same system under electric resistance hot water generation. This equates to an approximate 55% reduction in energy usage for the HPWH system during cooler fall months. Because the system is expected to operate much more efficiently in summer months, it is expected to have a 65% reduction on an average annual basis. This early data serves as an initial confirmation of the system’s effectiveness at its main goal — significantly reducing energy usage when compared to classic water heating methods.

Key considerations for HPWH systems

Central domestic packaged HPWH systems can significantly reduce energy usage and provide a consistent and reliable source of hot water for multifamily apartment applications and other building types that have a significant demand for domestic hot water. They also are well-suited for decarbonization projects, where building owners and their advisors are looking for alternatives to fossil fuels.

Systems are comprised of heat pumps, water storage tanks, a building recirculation system for supply line temperature maintenance, automatic system controls, and demand response communications linked to power utilities.

Engineers and owners should consider these types of systems for all buildings that have a significant amount of domestic hot water usage, especially all multifamily applications, which are experiencing the earliest adoption of this new technology.

The Advanced Water Heating Initiative is a stakeholder group of utilities, government organizations, and manufacturers that are working to support adoption and mainstreaming of this new system. They have a newly released specification that aids those looking to implement this type of system in their projects. Guidance on this effort can be found at www.advancedwaterheatinginitiative.org.

New technologies can often find it difficult to gain traction in the market. The interest in packaged domestic hot water systems has been significant since its launch last year. Proper system packaging has been key to the successful implementation of this project and will prove critical in the adoption of these types of systems. All projects should strongly consider or require a factory-packaged system and the benefits it delivers. Correct coordination of the components of the system, tested and reliable connections of piping and wiring, and confirmation of controls operation are all crucial to proper application of this system in the often-variable conditions of the job site. Packaged and repeatable systems, installed and verified under factory conditions, will enhance the installer’s confidence in the package, save them time on the job site, reduce the contractor’s risk, support the wider and faster adoption of this system type, and deliver energy efficiency and decarbonization to the entire market.