What captures the imagination of an engineer more than the elegant lumbering of a steam locomotive? The “stoker” shoveling coal into a firebox while the engineer sounds the train whistle to alert passersby. On one vacation when I was young, I remember my parents taking me on a train ride in the redwood forests of Northern California. Many areas of the country still have steam locomotive rides you can take. It’s fascinating to study the engineering of what makes a machine like a steam locomotive work. When it comes to utilizing steam for building systems, it can be daunting for plumbing engineers mainly because it’s just not as common as it used to be.

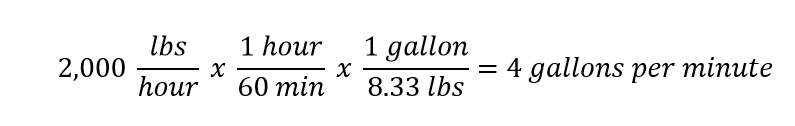

I had a design issue come up recently where I had to calculate the amount of treated water being fed to a clean steam generator. The purpose of the clean steam generator was to, quite simply, generate steam. The steam would be injected into an airstream in order to meet the minimum requirements for humidification, which my colleague explained, is prescribed in ASHRAE Standard 170 for health care facilities. The HVAC engineer shared the cut sheet for the steam generator with me and it was designed to use 2,000 pounds per hour of steam. I took a deep breath and prepared myself to brush away the cobwebs from my brain and do some serious calculations. How much treated water would I need to feed to this generator? The water required was being produced by a reverse osmosis system, so the quantity was important to get right.

The answer to the question: “How much water do you need to produce 2,000 pounds of steam per hour?” is basically 2,000 pounds of water. It’s the same question as “What’s heavier, a ton of bricks or a ton of feathers?” The equation above just converts the units from pounds per hour to gallons per minute. I was relieved, “that wasn’t so bad,” I thought to myself.

Understanding relationships

Another memory I would like to share is the time our thermodynamics class took a field trip to a WWII Victory ship that was docked in the Los Angeles Harbor. Our professor was a veteran who “teared up” as he explained that he had not been in a Victory ship boiler room since serving 40 years prior. Standing with him there in the boiler room as he brought his chalkboard teachings to life is still an inspiration for me. Thermodynamics is defined as the “branch of physical science that deals with the relations between heat and other forms of energy (such as mechanical, electrical or chemical energy), and, by extension, of the relationships between all forms of energy.” Professor DeSoto took real life experience working in a boiler room, educated himself theoretically and then taught his knowledge to others.

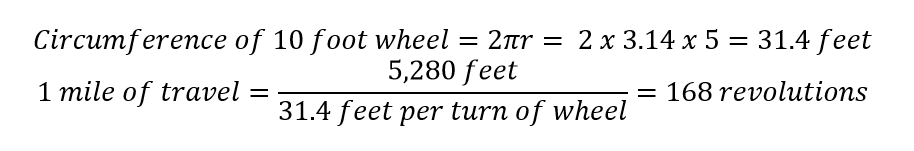

A big part of designing mechanical systems is understanding the relationships of different forms of energy as substances like air, water and steam get moved about and do the work we want them to do. The engine on Professor DeSoto’s Victory ship was most likely a turbine type where high pressure steam expands at reduced pressure in a piston and turns a shaft. This is an example of utilizing the transforming the kinetic energy of steam into mechanical work. A piston type steam engine, such as what we would imagine on a train locomotive, transfers the energy from a linear direction through a linkage connected to a wheel. We could estimate how much steam is utilized by calculating the volume of the piston, where a single stroke rotates a wheel of a given circumference and moves the train forward the distance of that circumference.

For 1 mile of travel, a 10-foot diameter locomotive wheel would need to turn 168 times:

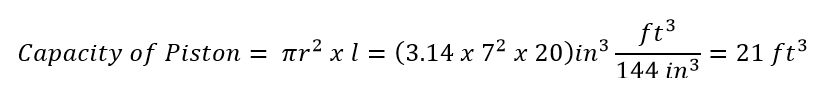

Now, this wheel is rotated by a piston rod connected to a piston. It takes a forward and backward stroke of the piston to rotate the wheel once completely. The piston will move one way as high pressure steam enters it and expands. Then, as the piston on the other side of the train does the same thing the first piston will move back and exhaust the steam that just performed the work in the first piston. Let’s say the pistons are 14 inches in diameter and 20 inches long. This means that the volume of a single piston is about 21 cubic feet. This is about 6 times the total capacity of a large V8 engine.

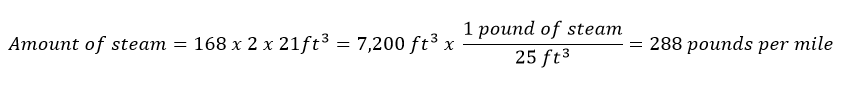

How much steam will we need to fill these pistons and get that train moving down the track? Referring to the steam tables, 1 pound of saturated steam will expand to about 25 cubic feet at atmospheric pressure. The volume of steam required will be 2 piston strokes for each revolution, times 168 revolutions for 1 mile:

Making a round trip to the beginning of our calculations, we can determine how much water we would need to drive a locomotive. Using coal to heat water and produce steam is how locomotives worked. How much water a locomotive could hold in the “tender” was one of the limiting factors as to how far a locomotive could travel between “fill ups.” 288 pounds of steam per mile translates to 35 gallons of water, and a tender that held 10,000 gallons of water could drive a locomotive about 200 miles before needing a refill.

Plumbing and HVAC engineers utilize steam to transfer heat for hot water and heating, or to improve comfort through humidification. Steam has a place in our imaginations as the method of driving locomotives and turbines. Like the expansion of steam from high pressure to atmospheric that drives a piston, we can expand our areas of study. Continue to educate yourself and your career will “pick up steam.” Whichever train you choose to get on, enjoy the ride!