A significant portion of the reason there isn't an even greater number of new technologies in current use in industry is because it isn't always easy for the consuming public to make the connection to the inventor's idea. Most industrial technologies don't embark on the sort of promotional campaign typically known to consumer goods such as automobiles or soda pop. It just isn't practical. So finding that gem in the rabble takes a bit of investigative work.

So when most of us casually see a segmented pipe coupler, something in our brain automatically associates it with pipe that has some type of special end. That is, after all, how traditional segmented pipe couplers work, by more or less latching onto a formed pipe end with either a bump or a groove or some type of permanently attached key. And unless you are prepared or otherwise used to buying the correct special pipe for the couplers, chances are these items never receive a second glance. But now, for those of you who want to use standard plain-ended pipe and were also interested in the possibility of using segmented pipe couplers, the time has come to give them a second look.

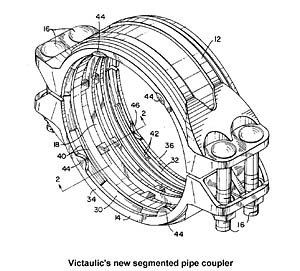

Recently, Victaulic Company of America in Easton, PA, developed a segmented pipe coupler that doesn't require those special ends of pipe! Patented January 9, 2001, under U.S. Patent no. 6,170,884, the "Pipe Coupling For Plain Ended Pipe And For Plain Ended Pipe Attached To Grooved Pipe" is the creative work of inventors William Ross McLennan and Dennis R. Brown, both of Easton, PA, and Douglas R. Dole of Whitehouse Station, NJ.

For the most part, the invention looks like any other segmented pipe coupler. There is a sealing gasket in the center (18 in Figure 1) to produce a leak-proof connection between the two pipe ends. But the real difference comes on closer inspection. Where normally this type of coupler would have contoured receivers or key receivers on the outer periphery, this coupler was twin "cutters" (40 and 42 in Figure 1) pointed toward the center of the joint.

These cutters are essentially long teeth that bite into the plain pipe end when the coupler is tightened down around the pipe. They are made from hardened high strength steel, and ground to a sharp edge on the inner site. Once fully embedded into the surface of the pipe, they are virtually the same as pipe threads holding against each other. The advantage over threaded ends is that assembly and disassembly are substantially more convenient without the need for a union fitting.

The advantages to this coupler are both convenience and cost savings. On the convenience side, it isn't necessary to find and secure quantities of pipe with the necessary special end formations suited to the particular segmented coupler one might be using. Standard pipe is substantially more plentiful, and therefore, readily available on short notice.

On the cost savings side, it's even easier to anticipate the advantage. Simply put, special ends on pipes involve some type of manufacturing process that carries its own costs. Plain-ended standard pipe is just about the least expensive prospect there is for accomplishing your task. Depending on a contractor's typical labor costs versus the price of these new segmented couplers, it is even theoretically possible that they may be less expensive than the combination of threaded couplers and the labor cost of cutting threads on pipe ends.

Of course, there are going to be circumstances where you might need to interface with existing pipe that already has formed ends or keys. The inventors have anticipated this situation, and one of the various "embodiments" of the invention provides for connecting these formed-end pipes to plain-end pipes. The interior of the coupler for these situations is provided with a receiver for the special-ended pipe on one side, and the cutter teeth for plain-ended pipe on the other side of the coupler. The style of the sealing gasket remains more or less the same.

It seems that, depending on your application, this coupling would almost assuredly be less expensive than traditional bolted flange connections, especially in light of the costs involved in first attaching the flange to the pipe ends. Unfortunately, there is no data included in the body of the patent to indicate what the pressure usage ratings for these couplers might be. Contact Victaulic for more information on this patent at www.victaulic.com.