Issue: 10/04

There are now a number of large-scale radiant slab (concrete core conditioning) building systems being designed and built around the world, based on initial projects that were developed in Switzerland and other parts of Europe some two decades ago. The track record of the older projects dating from the late 1980s and early 1990s have proven that this technique for building indoor comfort control can work very well and be a very low-energy-use building system. The learning curve that the original system designers have gone through is well-documented, and there are a number of detailed technical papers that have been published in the last few years that have outlined and described the effective tweaking of these types of systems to optimize both the indoor comfort and the low energy use.

Concrete Response Time

The radiant floor slab heating systems that have been used for a number of years, mainly in the residential dwelling sector of the industry in North America, are also well-known, well- documented and can be considered almost mainstream in terms of design criteria and application techniques. One of the key fundamental issues is that concrete mass is "difficult" to control because of its longer response time compared to conventional heating terminal devices (hot water baseboard, convectors, suspended radiant panels, etc.). Many folks still try to use night setback on a radiant heating slab to "save energy," as one would do with a conventional heating system. It just doesn't work. The concrete has a very heavy mass compared to conventional heating systems, and it takes a long time to cool down, and conversely, a long time to heat up. This time response actually leads to lower energy use if the slab can be maintained at a steady state temperature that is "trickle charged" to maintain the desired space temperature.

A fairly crude rule of thumb is that a concrete slab has a response time of around one to two hours per inch of concrete for a change in temperature. This means that most residential radiant slab floors that consist of about 1.5" (38 mm) of topping on a subfloor have a response time of around two to three hours, depending on the type of concrete mix. A suspended structural slab with a thickness of six to eight inches has an estimated response time of 10-16 hours or more. So, why would anyone try to control a radiant slab loop with a room thermostat and a control valve if there is more than a couple of inches of concrete used for the radiant slab?

Whole Building Design

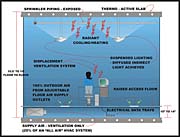

It is then incumbent on the building design team to minimize the thermal fluctuations in a space served by a radiant slab to work with the slow response time. The key, then, is a "whole building" design approach (building physics), where the building envelope and internal heating and cooling loads are designed in such a way as to keep the heat losses and heat gain fluctuations to low levels, within the capability of the radiant slab's operation. It's a bit of reverse engineering: The building envelope and internal loads have to be designed around the capabilities and thermal physics of the radiant slab. While the costs of high thermal performance glazing and exterior solar control may cause some concern, the point is that an integrated building design ought to be able to offset the added envelope costs with savings in the mechanical and electrical systems.

The nice thing about radiant temperature control is that the radiant heat exchange process takes place at the speed of light, so in fact, radiant heating and cooling systems can be considered to have a very fast response time from an occupant's point of view. Considering that the high thermal mass of a thick concrete slab can stay at a steady state temperature with a small amount of trickle charging, a radiant slab heating and cooling system can easily maintain a near constant space comfort condition, in spite of short-term fluctuations in the thermal loads in the space. If there is nothing in the room that is at a different temperature than the surface of the radiant slab, there is no heat transfer. As soon as a warm object like a human being comes into the room, there is instantaneous heat exchange with the radiant slab. If a small amount of solar load enters the space and heats up furniture, floors and objects, they exchange this heat with the radiant slab constantly at the speed of light. It takes a very long time for the slab to change temperature, even with steady heat exchange, so it can maintain a very stable indoor comfort condition, provided the water loops are constantly circulating and removing the thermal loads absorbed by the slab.

The Human Comfort Equation

The other thing to consider is that radiant heat exchange and radiant comfort are about 50% of the human comfort equation. The comfort conditions in a building with a combined radiant and air system have to be measured using the "resultant temperature." This means that the "air temperature" is not the true measure of comfort and cannot be used exclusively as the control point. For example: In a room that has an ambient air temperature of, say, 78

Controls

Conventional controls can be adapted to suit a radiant slab control system, provided the designers and control programmers understand the dynamic response of the slab and the zone it serves. Pulse-width modulation space temperature sensors coupled with slab temperature sensors can be used to provide a reasonably good control scheme, as long as the space thermal loads are carefully controlled and designed for. The design mindset for a radiant slab system application changes from being a "reactive" system design-one where the radiant slab designer is trying to design the slab to react to thermal loads due to building envelope, glazing solar loads and other sources-to a "pro-active" design approach, where the system designer tries to design the building envelope, glazing and thermal load generators to match the slab performance capacity. This latter approach results in a much better building envelope, which naturally leads to much lower energy use and stable comfort conditions. Isn't that what it's all about at the end of the day?

The Big Picture

If the application is a radiant floor slab with less than two inches of concrete, you may be able to successfully use individual slab loop control valves to provide fine-tuning individual zone control. But the primary heating water must be reset up or down on a seasonal basis, tracking the outdoor air temperature trends.If the application is a radiant cooling/heating ceiling system, with more than two inches of concrete, do not use any control valves on the individual loops, as they will not be able to control anything due to the long response time of the thicker slab. A constant flow/variable temperature system must be used, with the slab loop water temperature reset on a seasonal basis. Depending on the building thermal loads, duty-cycling the slab circulation pump(s) can also help reduce overall building energy use, while still maintaining good indoor comfort conditions.

The glazing at the perimeter zones of the building must be selected to insure that the inner surface of the glass does not go below 62