The use of plastic pipes in commercial applications has been steadily growing, driven by their versatility, cost-effectiveness, and durability. As we step into 2024, several key trends are shaping the landscape of plastic pipe usage in commercial markets. PM Engineer Chief Editor Nicole Krawcke sits down with Lance MacNevin, director of engineering, building and construction division of the Plastics Pipe Institute, to discuss top trends influencing the use of plastic pipes in commercial applications.

PM Engineer: what are the largest trends you're seeing for the commercial plumbing market as it relates to plastic piping over the next year?

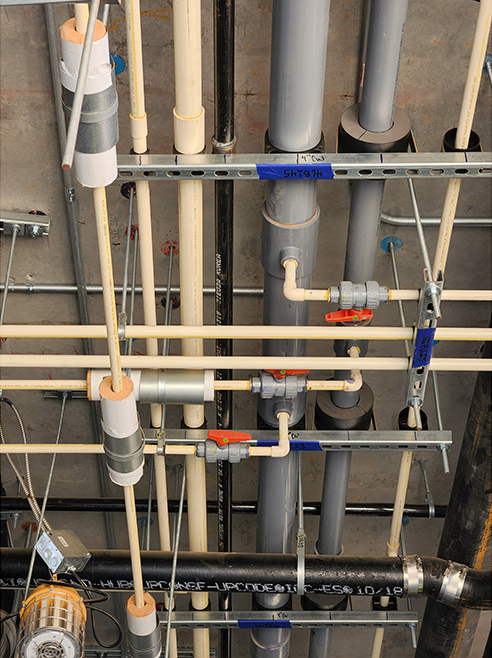

LM: The good news is we are actually seeing faster adoption of plastic pipes, especially over the last four or five years. So the types of pipes that are being used for the hot and cold water supply, and hydronic systems in commercial buildings are materials like PEX and some PERT, which is polyethylene raised temperature. CPVC has been used for decades in commercial plumbing and now also polypropylene. There are two types of that called PP-R and PP-RCT.

Examining plastic pipe trends in commercial markets

We're actually seeing a lot of adoption, especially over the last four or five years, as plumbers and commercial builders are recognizing the benefits of the material. One of those benefits that make a lot of sense, especially in commercial jobs, is easier installation, the fact that these materials are lighter weight and easier to transport — especially in multi-story buildings — they are safer for the workers to be transporting around the buildings because of their lighter weight and it's just easier to move the materials around.

But also, when it comes to joining the plastic pipe materials, we don't have any open flame. So if we're dealing with wood frame construction, which those buildings are getting higher and higher now, you don't really want a lot of open flame in those projects because it could set things on fire. With plastic materials, they're joined with mechanical fittings, heat fusion fittings or solvent cement fittings — all of those avoid the use of open flame. There's essentially zero fire risk when it comes to things like that. So these benefits combined can lead to faster completion when plumbers are dealing with plastic materials, as well as lower cost, stable pricing and great reliability because the materials have impact resistance and resistance to all the other hazards that you're going to find on a job site, and they've been proven to be durable, long-lasting and reliable.

“We're actually seeing a lot of adoption, especially over the last four or five years, as plumbers and commercial builders are recognizing the benefits of the material. One of those benefits that makes a lot of sense, especially in commercial jobs, is easier installation, the fact that these materials are lighter weight and easier to transport — especially in multi-story buildings — they are safer for the workers to be transporting around the buildings because of their lighter weight and it's just easier to move the materials around.” — Lance MacNevin

PM Engineer: How are plastic pipe materials addressing challenges that you'd run into on commercial applications?

LM: Well, some of those challenges have to do with sizing, of course, in terms of what size pipe should I choose for different situations. The manufacturers do help with design support in terms of interpreting the codes, understanding what the flow rates really need to be for different situations and then helping the system designers, the mechanical designers or the plumbers select the right pipe diameters.

There are also some great online software tools that allow engineers and plumbers to do this kind of design support on their own. In fact, PPI has an online calculator. You just go to plasticpipecalculator.com and it allows the user to select from any of the plastic pipe materials that we talked about, whether it's CPVC, PEX, PERT or polypropylene, and determine different wall thicknesses — whether it's SDR 9, SDR 11, Schedule 40 or Schedule 80, determine different flow rates and temperatures and determine what those pressure losses are going to be.

The other thing that's always important, whether it comes to commercial work — or any work — is manufacturer certifications. So the manufacturers do make sure that they have all the required certifications that are required for commercial work. And one of the unique things about commercial work is flame and smoke spread requirements, which you don't generally have those requirements in residential work, but in commercial work, if you are putting piping up in a return air plenum, typically that piping has to be tested and certified to one of the flame and smoke spread test methods. So the manufacturers have stepped up over the years, they've spent the money invested in the testing, and they all have their proper certifications to be able to show that their pipes will meet those flame and smoke spread requirements.

PM Engineer: The big issue in the industry lately has been sustainability. How do you think plastic pipes are contributing to sustainability in commercial construction projects?

LM: Well, and that's a bit of a tricky one to answer in the sense that sustainability can mean different things to different people. In one case, sustainability could be which product is going to last the longest, because if I had to replace it every 10 years, that's not very sustainable. Plastic pipes definitely address that because they all have designed lives in excess of 50 years, and most of these plastic pipe materials have been around for more than 50 years, so they have really long proven life in these kinds of applications.

Sustainability also has to do with the environmental costs of producing the products in the first place, whether that's the amount of energy it took, the amount of water it took, or other types of chemicals or environmental costs. We've seen through various lifecycle assessment reports that have been published by different agencies around the world, that plastics score far better than traditional metallic piping materials when it comes to those kinds of environmental energy requirements and water requirements because the plastics are just very efficient to produce. Most of the plastic pipes today are derived from crude oil and natural gas, but almost from the byproducts of refining crude oil and natural gas into the energy that we need for our vehicles and our buildings. A lot of those byproducts are actually further refined and then eventually adapted into the plastic materials that we use today. So there's actually pretty low environmental cost to producing these plastic pipe materials.

And then, with their lighter weight, a lot less energy involved with transporting the pipes around — you can get a lot more plastic pipe in a truck because, in a lot of cases, it's 25% of the weight of metallic pipe of the same diameter. So that's sustainable because you're putting a lot more pipe on the same truck, takes a lot less equipment to move it around on the job site.

Even with regards to the longevity of the pipe, like I said, they're proven to last a long time, but they also very strongly resist mineral buildup, which can actually choke off the inside diameter of a pipe over time and restrict the flow and increase pumping costs. That doesn't happen with plastic pipes. So if you're building a building to last for 50 plus years, you actually want a pipe that's going to stay clean all of that time and have consistent pressure loss requirements and plastic pipes also deliver that as well.

PM Engineer: What design considerations should plumbing engineers keep in mind when specifying these types of projects?

LM: There's a few factors. Part of it is the size range again. PEX and PERT are widely available up to 2-inch diameter. But if somebody needed an 8-inch diameter pipe, that's not available in PEX. So at that point, they should be looking to one of the rigid piping materials like CPVC, which is available in iron pipe sizes or polypropylene, which is available in a wide range of sizes and a wide range of wall thicknesses or dimension ratios based on the pressure rating.

That's one of the good things about plastic pipe — there's a wide range of wall thicknesses available to meet different pressure demands. So if you're a part of a building that only has 60 PSI of plumbing system pressure, you don't necessarily need a pipe that's rated for 200 PSI of pressure. In fact, you can use a thinner wall pipe and save some money and material by going with a pipe that more closely matches the exact pressure requirements of that zone of the building. That's one thing that can be done.

On the other aspect of design support, again, back to the manufacturer support and the design tools available from our own organization, PPI is also an ASPE continuing education unit provider, a CEU provider, and we have been for six years now. We have six different courses approved by ASPE. So for people who are looking for some preliminary design support or design guidance, we're happy to provide those educational courses as online training. We can do it over the web or live to a group of people. Even if there are three people in an office somewhere, we can do that training with them, customize the training for exactly what they're looking for and give them the kind of information they're looking for.

One of the design considerations that they should pay attention to though is fluid temperature. Now, in most of these high-rise buildings, there's not really a need to have fluid temperatures or hot water temperatures beyond 135° F. You generally want to keep your return temperature at 122° F or above to prevent the growth of Legionella. And all of these plastic pipe materials are certified for continuous use up to 140° F. So they can do that. But, if for some reason, somebody was designing a commercial plumbing system that needed continuous fluid temperatures above 140° F, at that point, that may be pushing it beyond what the plastic materials are designed to withstand. So they would have to reach out to the manufacturer to find, "Can I use this exact pipe in this particular high-temperature application?" But those situations are really rare and generally don't make much sense in terms of why you would need to run hot water at such a high temperature because it's just not energy efficient to do that.