For over 10 years, Inland Sales Group has been trying to raise awareness of Legionella. Most people in the United States know nothing about it — where does it come from, how does it get into our bodies and what does the plumbing world have anything to do with it?

Most of us in “the know” are aware of the place and time the Legionella story started: Philadelphia 1976. In January of 1977, the CDC put a name to it — Legionnaires' disease. I am still convinced if the CDC had selected any medical type of name, we would not be talking about this now. Most people, when they hear Legionnaires' disease, they think about the elderly and the sick. Yes, those are people that are most commonly affected, but it certainly is not limited to as we have seen in the past few years.

Our industry can be a game changer for Legionnaires' disease, it just takes a little effort and understanding. Inland Sales Group does a great deal of work with facilities, hospitals, nursing homes, medical office buildings (MOBs) and much more. We often find that most building operators and/or owners have limited understanding of Legionella and how it can affect them and their building occupants.

Leonard’s Nucleus models give plumbing engineers complete system monitoring with outlet temperature control within +/- 2° F from set point, regardless of demand. Features include user programmable set point, integral daily sweep and sanitization.

Leonard’s Nucleus models give plumbing engineers complete system monitoring with outlet temperature control within +/- 2° F from set point, regardless of demand. Features include user programmable set point, integral daily sweep and sanitization.

Inland Sales Group has done several lunch and learns with these facilities and their maintenance and operation personnel. Most of the time, they are being told what to do with sampling, flushing and the like. In reality, almost all of them have no idea why they are doing it and what difference their efforts make. Hence, the problem today.

Our industry has had standards about Legionella dating back prior to 1997. These standards told us a great deal about water temperatures and mitigating Legionella from our piping systems. Legionella does not die but becomes dormant under 64° F. It thrives in temperatures from 90° to 115° F. So, both the cold water and hot water lines can be suspect to the bacteria. The flow of the water in the piping system is the most important part of any Legionella control. Hot water does, however, play a key role in whether it will grow or not. Here are a few samples of some early standards:

Allegheny County Health Department:

- First released guideline on Legionella Prevention (Jan 1997); and

- Provided direction on sampling and awareness that colonization occurs for the bacteria at temperatures < 122° F.

Provided disinfection measures:

- Copper-Silver Ionization;

- Thermal Eradication (“heat and flush method” — flush system for 20-30 minutes at > 158° F; also directed to store hot water at 140° F);

- Chlorination;

- For instantaneous steam heating system — flash heat water to > 190° F; and

- Ultraviolet Irradiation.

Below is another example from ASHRAE 2000 on temperatures:

- “Cold water should be stored and distributed below 20° C (68° F), while hot water should be stored above 60° C (140° F) and circulated with a minimum return temperature of 51° C (124° F). However, great care should be taken to avoid scalding problems. One method is to install preset thermostatic mixing valves.”

- “Where decontamination of hot water systems is necessary…the hot water temperature should be raised to 71-77° C (160-170° F) and maintained while progressively flushing each outlet…. minimum flush time of five minutes recommended by the CDC…”

We could continue to reference standards and other articles or white papers over the last many years, but, at the end of the day, if our building owners and designers don’t take these into consideration while remodeling or building new, they just are not making any impact.

ASHRAE 188 from 2015 was a great start with planning and progress. It put the ownership into a position for creating water management teams, data collection, building awareness and to create plans for when you have a problem or outbreak.

What these standards never say is, “do it this way and you will be protected from Legionella bacteria.” That is because there is no silver bullet. There is simply no one way to build a building and protect it 100%. In most cases, it will require a few different forms of mitigation to achieve success. One of the easiest and most important fixes is the hot water system design.

Inland Sales Group has sold Leonard Thermostatic Mixing valves for over 25 years and we have seen everything under the sun, and still do today. Each hot water system is different, and there are a multitude of ways to accomplish getting hot water throughout your building.

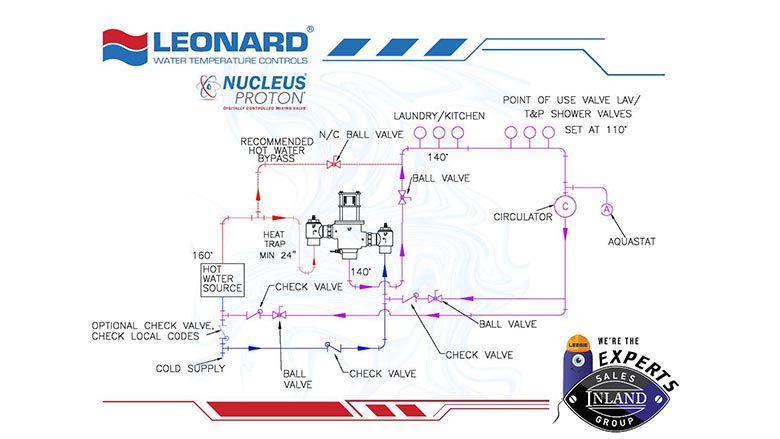

We put a design practice in motion several years ago with great success and help in keeping the hot water safer and more efficient. The drawing below in Figure 1 will give a quick basis of understanding on how this design is laid out.

Figure 1

The design features:

- Tank Temp/Heat Source = 160° F — Legionella dies instantly at 158° F;

- ASSE 1017 Digital Master Mixing Valve in mechanical room.

- Setpoint of 140° F;

Now, we will leave the mechanical room with 140° water and run through the entire building. Legionella dies within 32 minutes, so there is continual effort to control.

- We can now feed our kitchens, mop basins, hose stations, ASSE 1071 Emergency Mixing valves and any other area of the building needing hotter water;

- Point of Use Temperature controls to regulate between 110° and 115°, as needed;

- ASSE 1070 Point of Use valves for sinks, lavatories or Pressure Balanced Shower Valves;

- ASSE 1016 Thermostatic or T/P Shower Valves and set to safe temp;

- ASSE 1069 Valves for single push button showers;

- Recirculate as close as possible to all fixtures. Look to flow splitters to assist;

- Minimize dead legs — both for hot and cold water; and

- Circulation pumps run 24 hours a day.

As previously stated, the hot water system is only one aspect of mitigation but is the easiest one to understand and implement.

As we continue to spread the word, ASSE joined the fight several years ago with the ASSE 12000 certifications for contractors, facility managers and industry professionals. Several states are trying to get legislation moving forward but it has been proven very difficult.

The hot water system is only one aspect of Legionella mitigation but is the easiest one to understand and implement.

The hot water system is only one aspect of Legionella mitigation but is the easiest one to understand and implement.

Medical facilities and nursing homes have to have a water management program in place. Most hospitals do, but nursing homes are behind. In the State of Illinois, these types of facilities are mandated by law to do Legionella testing, but that does not give them any insight on how or what to do. It should tie into your water management team, although, if that team lacks knowledge, it will continue to be a struggle.

As a nation and industry, we can continue to press for awareness and understanding. If the end users and owners know what is at risk and are willing to work towards the end goal of eradication of the bacteria, we can win.

There are many different ideas and philosophies on all of this, but simply put, there is still a major part of our industry and nation that knows nothing about Legionella. If we can make our nation aware of the issue, we can beat the issue.