Gary Hayden is a man of many talents. A licensed Professional Engineer in Virginia and eight other states, the 63-year-old’s career has taken him from product development to design and finally, the implementation of radiant and hydronic systems. After working for several industry manufacturers, Hayden decided it was time to go his own way, forming not one, but two new companies: gbH Engineering, a consulting engineering company focused on forensics, engineering and product development; and Premier Comfort Systems, a Class A design/build contracting firm specializing in hydronic technologies.

A past member of both ASHRAE, ASME and the Radiant Professionals Alliance (RPA), Hayden held various leadership roles in ASHRAE and served as a past board member of the RPA, and has written numerous articles on hydronics for PM Engineer, Plumbing & Mechanical and other industry publications. His vast knowledge and experience in understanding theory and implementation of hydronic radiant systems, and his willingness to use his expertise to help others has earned him accolades as PM Engineer’s 2022 Mechanical Engineer of the Year.

Getting started

Growing up, Hayden moved around a lot with his family, as his father spent 20 years in the Navy as a torpedoman before retiring as a Navy Chief.

“It seemed that every place we moved changed my trajectory of where I would end up,” he says. “We spent some time in Groton, Connecticut, and I was thinking more of a technical route. But then we moved to South Carolina, and once there, I started thinking more about engineering school. My dad was always hands-on, and I spent a lot of time with him. I remember different projects we would work on where I would get stuck and he would help me finish them. He was very good at mechanical and electrical things and was a master electrician after he got out of the Navy. My dad and I were always fixing a car or something around the house. So after graduating high school, I chose to attend Clemson University — I was accepted to a couple of other schools, but Clemson was in-state, so it was much more cost-effective and it was known for its great engineering program.

“I always felt like, as an engineer, I would have the opportunity to always get out from behind the desk if I wanted, and get into the field to do the work myself,” he adds. “I feel like when you're in the actual world of doing the work, you better understand how to do the engineering part.”

After receiving his engineering degree, Hayden spent time in several jobs doing everything from product development to technical sales to quality control.

“I took a job working for a mechanical contracting company on my own in a quality control role where they were building a naval laboratory building,” Hayden explains. “I was looking for a more stable job at the time, and my father-in-law came to me with ad that he found in The Washington Post for a company that was looking for an engineer to help them market and develop a product line. It was REHAU. So I went to work for them for about six years as the only engineer working in their marketing department, assisting with the development of their plumbing and heating system programs for the U.S. market, which was all based on PEX technology at the time.”

During that same time period, the world of plastic pipe exploded.

“It’s when polybutylene came off the market as a result of the famous ‘60 Minutes’ episode and PEX came on the market,” Hayden says. “I saw that whole evolution from when PEX couldn't get anybody's attention as long as polybutylene was out there. And as soon as polybutylene went away, PEX had everybody's attention. I saw all the companies that were involved in plastic pipe at the time — it was really intriguing.”

After six years at REHAU, Burnham came calling for Hayden. “What I did in six years at REHAU, I basically did in six months at Burnham. The market had really evolved a lot, but, at the same time, I knew quite a bit about how to get there.”

Hayden spent five more years with Burnham when the company decided to get out of floor heating and eliminated his position.

“The timing was right — I saw it as an opportunity to strike out on my own,” he says.

So, in 2002, at 42 years old, Hayden decided to move back to his hometown of Norfolk, Virginia, and started not one, but two new companies.

The best of both worlds

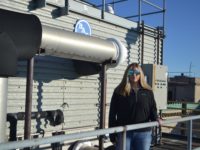

Hayden decided to get back into the field and opened Premier Comfort Systems. He was also doing engineering work at this time, assisting a couple of manufacturers with product development, and designing many different projects, including a rainwater to toilet flushing system.

“You read all these books about how to make it as a business owner, and they all say you have to focus on one thing so you’re not going all over the place. My one thing evolved around water — it’s either plumbing or heating. Then I realized the need to learn about refrigeration with heat pumps, so I did because that’s the majority of my market. And about nine years ago, there was a government downsizing. A ton of contractors came out of the woodwork all of a sudden. But they really didn't know how to price themselves in the market, and they were undercutting a lot of the regular contractors, so we were losing work to them. I started looking at myself and I said, ‘Well, I have an engineering degree. Maybe I should use it. And I'm a PE, so maybe I should use that too.’ So I decided to go into forensics with my engineering firm, as I had always been intrigued by forensics and the pinnacle position it held in the engineering world.”

gbH Engineering received a contract with Rimkus and Hayden started doing forensics projects for the company, looking into why an installation failed or how a product became damaged. Now, he’s done close to 400 projects for the consulting group over nine years.

“Working between my two companies, I’ve done everything from boiler explosion failures to consulting projects for manufacturers to what I call boutique design-build projects,” Hayden notes. “I was doing all the work from specifying to designing to installation. It was a complete turnkey opportunity to do some interesting projects. The Manion family is one my clients that turned into good friends (as it seems the way most of Hayden’s projects go), and I’ve done some really great projects for them. They gave me the budget and the freedom to really go after it. I always thought it would be fun to have opportunities like that.”

The latest project being a cottage house the Manions planned for many years to follow their retirement on an amazing site overlooking the Blue Ridge mountains, 15 minutes from downtown Charlottesville, Virginia. The house took four years to build.

“It has some really neat systems,” Hayden explains. “It has PV solar, geothermal, radiant floor heating, chilled and hot water heating ducted system, geothermal assisted domestic hot water, greenhouse radiant floor and air heating /cooling, a geothermal augmented heating system to heat the pool water, heated stone walls, outside air exchange and humidity control to protect the hardwood floors. The garage floor is also radiant heat. One of the things you fight for as a mechanical contractor is space to put your equipment, and they gave me a whole basement room. It was nice.”

The relationship with the Manions started in their Virginia Beach, Virginia, house with a floor heating system installation during the remodeling of their kitchen, and the renovations continued, including a major renovation to the master suite and upstairs bathrooms.

“One day, the owner and I had a discussion where I was approached to consider doing the master suite renovation after several contractors who were interviewed were not working out,” Hayden says. “We found that we were good at doing projects together, so my company was hired.”

This was Hayden’s motivation to take his company into Class A contracting. The new work included innovative installations of shower sprays in a shower made of glass block, a radiantly heated ledge stone wall, wall mounted toilet, heated towel bar using recirculated domestic hot water for year-round use and radiant heating for hardwood and carpet. Eventually, work on Manion projects has seen the replacement of equipment that Hayden's company installed back in 2008 with new inverter chillers and the latest condensing boilers. The joke was all the projects revolved around a good shower. Another notable Manion project was the modification of a metal spiral staircase in a glass tower to perform like a giant radiator. These installations are all “really cool.”

Other projects he’s completed include VRF, geothermal, chilled water cooling, warm water radiant and more. His company has installed many boilers, heat pumps, air conditioners and furnaces as well, so no job is too big or too small in the residential world, he notes.

Hayden doesn’t have regular employees; he contracts with retired master mechanics and skilled labor who have flexible hours to address new projects.

“I hire when I need them, and they are thrilled to work on both the simple and complicated projects,” he adds. “One of my master mechanics is an expert in sheet metal ductwork. He can build anything out of a tool bag.”

Key to success

From a contracting standpoint, Hayden notes the key to success is all about picking the right products from the right supplier so that in case something goes wrong, you have support from the manufacturer since the supplier has the attention of the manufacturer because of their business relationship.

“If everything goes right, everybody’s happy. But if something goes wrong, you need the manufacturer to step up and help you figure it out,” he explains. “Normally, manufacturers are not interested in helping with the cost of labor, but they’re great at providing parts within warranty. As a contractor, you might as well accept that this is going to happen. That’s why you want to be careful about which suppliers and manufacturers you’re choosing. It all comes down to relationships within the industry from the wholesaler / supplier to the manufacturer, and it all starts with the person at the counter with good backup from the store manager.”

Hayden also notes that it’s important to never stop learning both in the engineering and contracting world. “The key is to keep learning — learn all you can and have a good network of people that you can learn from and call on to help you when you need it.”

Hayden said that one of the best compliments he ever received was from Jim Roche, a famous long-time technical trainer for Burnham (Mr. Steam) that said he was one of the best-networked guys he knew.

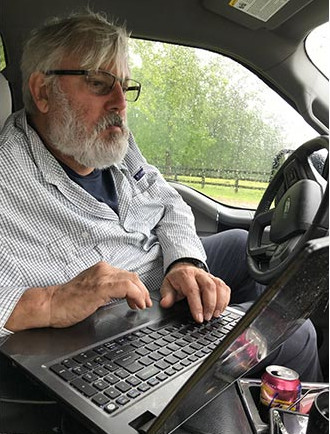

“I’ve got guys (both fellow engineers and mechanics) that I can call on when I’m working on a project and it’s not going the way I think it should go, or if I want to make sure I’m doing something the right way,” Hayden says. “It’s important to have that network to give you confidence in what you’re doing. I’m one of those guys that drives back to a project to make sure I didn’t forget something. As a forensics engineer, I’ve seen almost all scenarios, so I don’t want to see it on my projects. Sometimes, I lose sleep over it thinking, ‘Did I remember to do that?’ And I’ll go back and look. I like to take a lot of photos so I can also go back and look at those. And with camera phones, it’s so easy to do.”

Another part of being successful is the ability to listen, and Hayden is a great listener, according to Derrick Eason, a counter salesman at R. E. Michels. The two have become friends over the years. They even attended the Clemson University versus North Carolina State football game in October to watch Eason’s son play for NC State.

“Gary is a funny guy — I like that he can go from a suit to getting dirty,” Eason says. “He’s real versatile and just down to earth. He can get real technical or he can just level with you. He always does his research and he has great knowledge in hydronics. He has a real uncanny ability to fix boilers, and anything having to do with hydronics, water and heating, really. He’s good at it, and I trust him. But the biggest thing is he listens. He doesn’t always think he is right. He’s an all-around great guy. He helps a lot of people and he never mentions them. If someone doesn’t have heat or money to fix the issue, he helps them. I donate used parts that are collected from scrapped equipment to him for those jobs because I don’t want to see anybody in the cold or burning up in the heat. He’s a good dude. He deserves this award.”

Jamie Brawley, senior practice leader — Northeast region for Rimkus, met Hayden when he hired his firm to work as a contract forensic engineer. Brawley has watched Hayden evolve in the forensic world the past nine years, and Hayden has also done some contracting work at his house.

“Gary’s background was exactly what we were looking for at the time,” Brawley says. “He had a lot of HVAC experience and previous forensic experience, and I liked him.”

It turned out to be a good fit.

“Gary is really prompt — he gets down to the heart of the matter and keeps Rimkus informed through the entire process. He manages the projects well, keeps his clients informed and writes very well. Those are hard things to find in a lot of engineers. They’re not all good writers. In this industry, written communication is half of what we do. Our only product is written reports, so someone who can write well is really valued. He’s very experienced and detail-oriented. He likes to dive into a problem and find the root causes. I really enjoy his company and consider him to be a really good friend.”

Heart of gold

Outside of the office, Hayden loves fishing and camping. He actually purchased a 1972 Boston Whaler he spotted for sale while doing a forensic inspection at a mechanical contracting firm and restored it. He also found an Rpod camper on Facebook Marketplace that he and his wife have really enjoyed.

But the one thing about him most people don’t know is he loves helping people. As Eason mentions above, Hayden often helps those in need.

“I’m on the Nextdoor network for my neighborhood, and I see people asking about recommendations for help with their heating system,” he says. “I’ve slowly learned not to answer because everybody else’s guy is smarter than I am. They all have a guy they like, which is fine. But what they don’t know is if they were to call and ask me, I’d probably come over and fix it for them at no charge because they’re a neighbor. If it was a whole system, I would have to charge for that, but if it was something simple and reasonable where I could keep heat on in their house, I would do it. I’ve done it before.

“My neighbor across the street — I love him to death — is 84,” Hayden adds. “I tease him that he’s forgotten more stuff than most people know. He called me up the other day and said his boiler was not coming on. I put this boiler in for him about eight years ago. So I went across the street to check it out. The first thing I noticed when I looked at his boiler was there's no power on it. So I said, ‘Okay, wait. Ray, you have no power on your boiler. Let's figure out, where did the power go? Where is it turned off?’ So I go to a breaker box and check power at the switch. I got power at the switch to turn the boiler off. So I was perplexed. I thought, ‘Maybe the wire went bad.’ I mean, that would be really unusual, but possible. I kept looking behind the wall where the switch is, and boom, I’m inside a closet. All of a sudden, I see another switch. So I hit that, and Ray calls out that the boiler was back on. I didn’t know that switch existed. Then, Ray remembers about 10 days ago, he was in that closet looking around and turned the switch off. The switch was part of an old timer system commonly found on old oil-fired boilers. He accidentally tried to stump me, but I figured it out in the end. I’m happy to help him — to help all these guys. All they have to do is ask.”

When asked about what advice he would offer someone aspiring to be an engineer, Hayden does not hesitate to say it’s really important to be not only a book person, but also a hands-on person.

“If you have an opportunity to get in and help a mechanical contractor during the summer in between semesters or even get some kind of a co-op job where you're involved with being out in the field and helping them do projects, that is the way to go,” he says. “I was fortunate that I had a lot of those experiences and especially since my dad was all hands-on, but I think that being hands-on helps you appreciate the work somebody's doing in the field working off your designs. Don’t get a job flipping burgers. Get a job in the industry — work as a helper for a plumber — they need help. There’s a lot of opportunities out there. Don’t be afraid to get dirty. I’m 63 and I still go under houses.”

Hayden has said jokingly many times that his company motto is: “If it were easy, someone else would be here”.