Innovation often starts within research facilities, which is certainly the case for a large university in the mountain region of the USA. When this facility needed to install a new piping system to support research and development efforts at its food and water laboratory, they looked to a local distribution company for expertise. Shyne & Associates, based out of Colorado, has serviced the plumbing industry for over 60 years by providing products that meet the needs of engineers and design firms across their region.

While it may sound “simple,” designing water-handling systems can be just as complex as designing systems that handle aggressive chemicals. Establishing and maintaining pure water can be a critical part of engineering behind these installations. This is especially important in a research facility, where pure water is crucial to ensure accurate measuring of testing protocols and data. Shyne & Associates helped the university choose a material that does not impart excessive leachables or other impurities into the product stream.

To make the matter even more complex, this system also had portions that were installed within the plenum space. The plenum space is specifically designed to funnel air flow and circulation throughout the building. While typically located between the structural ceiling and the drop ceiling, the plenum space is subject to stringent design requirements. In the early 1980s, a fire at the MGM Grand in Las Vegas spurred these codes, since the smoke generated in the plenum by flammable materials unfortunately caused fatalities. Since then, the industry has mandated designing with materials that meet the stringent requirements various codes and standards.

The high purity and need for plenum compliance led the university to install a system manufactured with Polyvinylidene fluoride (PVDF) resin. While naturally a pure material, PVDF resins fall into a family of materials known as fluoropolymers. Other characteristics of fluoropolymer materials include exceptional flame and smoke resistance, broad chemical resistance and high-temperature capabilities. One of the differentiating factors of PVDF materials compared to its fluoropolymer counterparts is its higher crystallinity. This property translates to higher mechanical stability, abrasion resistance and permeation resistance. PVDF is also an upgraded solution for commodity materials such as PVC, CPVC, polyethylene and polypropylene, which may face difficulties in high temperature or chemically challenging applications. PVDF makes an excellent choice for piping materials because it is able to retain its strong properties even at elevated temperatures. Figure 3 below shows recommended continuous use temperatures of commonly used plastic piping materials.

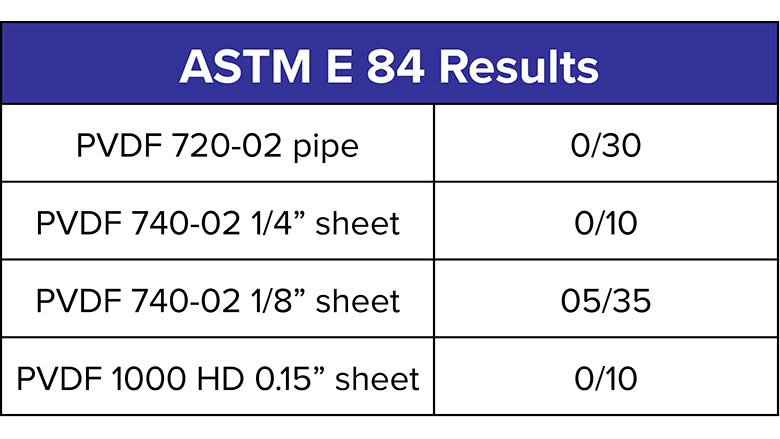

PVDF materials also comply with the standard regulating plenum usage — ASTM E84. Known as “The standard test method for assessing the surface burning characteristics of building products,” ASTM E84 gives material ratings for both flame and smoke thresholds. In order to be compliant, materials used within plenum spaces shall have flame spread no more than 25 and a smoke developed index no more than 50, otherwise known as 25/50. Certain grades of PVDF possess the unusual ability to pass the ASTM E84 25/50 test with no modifications to the test. Table 1 below shows the ratings for two grades of PVDF materials.

It is important to note in the table above that only certain formulations of PVDF materials pass plenum codes. Shyne & Associates has worked closely in conjunction with Arkema and Watts Orion in supplying these grades. Arkema, the raw material supplier of PVDF resins, has developed two specially formulated grades for plenum-rated PVDF piping, which complements their portfolio of over 40 different grades of PVDF and PVDF copolymers. PVDF 1000HD is a FDA rated version of PVDF that also has plenum compliance. PVDF 740-02, while not FDA rated, is often used in chemical handling applications requiring plenum ratings, such as laboratory waste drainage systems.

Watts Orion has been manufacturing PVDF piping for over three decades and has a long history of supplying the industry with many easy-to-install options. Joining methods for PVDF drainage pipe range from electrofusion, socket fusion and butt fusion. Watts can standardly supply PVDF waste drain pipe in sizes from 1 1/2 inches to 12 inches and is able to fabricate special components upon request. They offer two lines of plenum-rated piping utilizing both of Arkema’s plenum-rated resins: Whiteline and Plenum Plus PVDF.

In this specific case, the choice of using PVDF 1000HD was important, since purity was critical for the water system. MTech Mechanical, a large and locally owned full-service mechanical contractor, completed the installation. Their expertise in servicing educational as well as health, industrial and governmental facilities made the piping and plumbing installations seamless. Using Orion’s Whiteline PVDF, piping was installed from 3/4-inch to 2-inch sizing and the system was completed with valves and fittings. Socket fusion was the preferred joining method due to the ease of making a strong, reliable joint that can handle the array of chemicals.

John Masucci, plumbing field manager at MTech Mechanical says, “The PVDF product is very easy to use and quick to install. We were given a demo for all of our field employees and they were quickly certified on the product installation. With just a few simple tools, this product can be easily installed saving time and money in the field. It offers a great product to the end-user with lots of fittings and valves to choose from.”

While PVDF systems are upgraded solutions and carry higher costs that more commodity thermoplastics, the design requirements for plenum and purity made PVDF and best option.

Food and research laboratory installation using PVDF pipe. Photo courtesy of Mtech Mechanical