Legionnaires’ disease, first identified in 1976, is caused by water contaminated with Legionella pneumophilia which, when disseminated in droplets into the atmosphere and inhaled, may infect a person. The interest and concern in Legionella management and control within building water and air systems has continued to grow as Legionella outbreaks increase. Although plumbing systems are a common source of such outbreaks, mechanical systems such as cooling towers, air distribution systems, spas, fountains and hot water tanks can also act as breeding grounds for the bacteria that causes Legionnaires' disease.

During the 2024 edition of the Uniform Mechanical Code (UMC) code cycle, the UMC Technical Committee formed a task group to address Legionella in mechanical systems for the UMC. Prior to the formation of this group, the Uniform Plumbing Code (UPC) Technical Committee formed a task group for the 2021 edition of the UPC, which resulted in the creation of a new Appendix N, “Impact of Water Temperature on the Potential for Scalding and Legionella Growth.” The Uniform Codes published by IAPMO consistently endeavor to integrate major health and safety concerns, earning the reputation of being all-inclusive safety codes in an ever-changing environment. The UMC is developed via an ANSI-approved development process, which ensures consensus and due process in its development.

Water management program

Legionella outbreaks are more likely to occur in buildings with mismanaged water systems and in stagnant water. Therefore, a water management program is the preferred approach to controlling Legionella in building water and air systems. Legionella bacteria thrive in cooling towers where standing water is common.

A Legionella management plan should include preventive measures for all systems that present a significant risk of Legionella growth and transmission. Where a management program is implemented, it is typical for a water management team to be formed to provide a description of the water system, identify potential areas of Legionella growth with temperature ranges, etc. A water management program may be established when required by the authority having jurisdiction.

Cooling towers

Cooling towers, evaporative condensers and indirect evaporative air-cooling equipment are standard components used in large building air conditioning systems and have been the source of numerous Legionella outbreaks. These systems use the natural cooling process of evaporation to remove heat from water or to directly cool the air. The warm and wet environment of cooling towers provides an ideal environment for Legionella to grow.

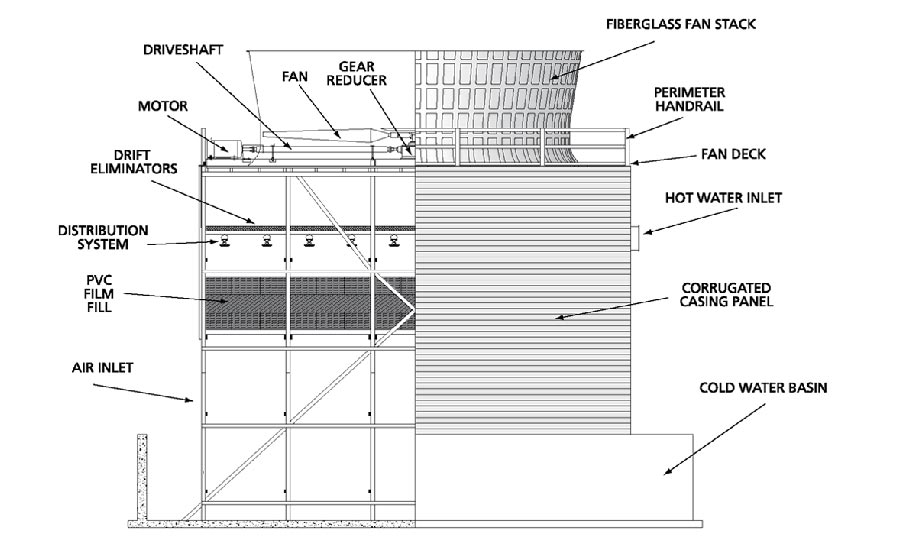

Legionella control in cooling towers should start early, preferably during the design and commissioning phases. Chapter 11 Part II of the UMC addresses the installation and construction of cooling towers. Section 1122.0, “Chemical Treatment Systems,” has been a useful resource for developing a water treatment plan using chemical disinfectant. Section 1126.0, “Drift Eliminators,” requires drift eliminators to be installed in cooling towers to reduce the quantity of mist or water droplets that is carried away from the cooling tower. Drift eliminators can assist with reducing the spread of waterborne pathogens into the airstream. Compliance with these code requirements will ensure a safer and more efficient cooling tower. The Legionella Task Group will look into expanding these safety provisions for cooling towers.

Regular monitoring and testing of the water quality are some of the most common steps used to control Legionella growth. It has been recommended to check cooling water chemistry, pH levels and total bacteria count a minimum of twice a week. Monitoring and testing may be accomplished by sampling the water. Testing should be done regularly. Routine monitoring can helP evaluate the effectiveness of the water management program. Interpreting Legionella monitoring data must also include how to respond to certain Legionella levels. If high Legionella levels are found, the water treatment program should be adjusted as needed. Although there is no established Legionella concentration necessary to cause an outbreak, levels above 10 CFU/mL (Colony Forming Units per milliliter) are commonly considered a cause for concern. Remediation actions may include additional chemical treatment and maintenance procedures.

The major components of a cooling tower include the cold water basin, air intake louvers, fill media, water distribution system, fan deck, drift eliminators, fan motor, and fan discharge. Image courtesy of SARA Cooling Tower Co.

Codes and standards

These days, there is no lack of safety guidance documents, standards, regulations and policies intended to assist building owners and managers in controlling Legionella in buildings. No list would be complete without mentioning ASHRAE 188 and ASHRAE Guideline 12. These documents have proven to be industry standards for Legionella risk management and have gained the reputation of being reliable sources for Legionella control. The goal of all such guidelines should always be to ensure the health and safety of the public.

The UMC Legionella Task Group is an extensive and diverse group with knowledge and experience in mechanical and plumbing systems. The UMC Legionella Task Group will provide recommendations to the UMC Technical Committee for consideration to the 2024 edition of the UMC. The UMC continues to address the most important issues to serve the industry and to include all major industry standards within its contents to ensure public health and safety. The UMC, along with the other IAPMO codes, strives to keep up with the times in which we are living to address the most significant areas of concern within building mechanical systems in our ever-changing world.