When the ink was dry on the market forecasts for 2020, nobody could have predicted a global pandemic disrupting every facet of the U.S. economy.

However, those are the cards the industry was dealt. Commercial buildings were shuttered for weeks — sometimes months — as states issued stay-at-home orders to slow the spread of COVID-19. This presented a multitude of new problems for the building trades.

Many plumbing and mechanical contractors and engineers experienced delayed or cancelled commercial projects last year, which is essentially forcing the industry to embrace new technologies and creative building strategies.

“On top of projects being put on hold because of the coronavirus pandemic, one of the biggest trends has been an increased demand for prefabricated spools, manifolds and runs of pipe,” notes Barry Campbell, vice president of marketing, Aquatherm. “With concerns about the skilled labor shortage, social distancing, jobsite safety and the usual concerns about keeping projects under budget, mechanical design and installation teams are embracing the concept of working with piping solutions providers like Aquatherm who can provide prefabrication. The main driver for this is that they can save time and money with scan-to-fab and all the support the Aquatherm team delivers.”

Campbell points to a recent upgrade of Old Dominion University’s central utility plant as an example. Aquatherm supplied more than 700 feet of Blue Pipe SDR 17.6 for the project in Norfolk, Virginia. A project of this scale that normally would have taken four months to complete was finished in five weeks, he explains.

“Tough, durable and lightweight polypropylene piping can be installed considerably quicker than welding carbon steel,” Campbell says. “It is also much easier to prefabricate offsite and ship to the jobsite and then get in place due to its being up to 70% lighter than carbon steel pipe, depending on the pipe’s diameter and wall thickness. These benefits may be especially important in 2021 if investors want to begin or resume projects that were put on hold during 2020.”

Nathan Hortness, category manager – industrial for IPEX USA, notes that thermoplastic piping systems are gaining market share each year.

“Thermoplastic piping, of which CPVC is a dominant player, growth is to a large extent dictated by its competitive installed cost, long-term reliability and ease of installation,” he says. “The rising cost of single-family dwellings has resulted in an increase in residential mid-rise and high-rise construction, an area where Xirtec CPVC made with Corzan CPVC is uniquely well suited; due to its lower cost, ease of installation and long-term performance compared to alternate materials.”

A resumed focus on hygiene

According to Mark Lawinger, senior product line manager, Flushometers and Fixtures for Sloan, the ongoing trend in 2020 was the importance of hygiene and hygienic products due to the COVID-19 outbreak.

“Hygienic products — especially touch-free restroom products —are a theme that will only continue to gain momentum this year and moving forward as facilities retrofit from manual to sensor-based upgrades. By now, we are all well aware of the importance of hand hygiene and guarding against potential cross-contamination on ‘high-touch’ surfaces. Restroom guests feel most comfortable in an entirely touch-free environment, where flush valves, faucets, soap dispensers, hand dryers and more are all sensor-operated.”

Kris Alderson, senior marketing manager, Bradley Corp. agrees, saying upgrading restrooms with touchless fixtures is the hottest trend right now.

“The 'hands-free' trend has been growing for years,” Alderson says. “Touchless benefits such as user convenience, minimizing germs, cleanliness and ease of maintenance have always resonated with the commercial plumbing market. But in 2020, the coronavirus pandemic accelerated demand for touchless technology, making it the new gold standard in restrooms.”

Bradley’s 2020 Healthy Handwashing Survey showed 91% of Americans think it’s important that commercial restrooms be equipped with touchless fixtures, and 90% say that their preference for touchless handwashing fixtures has risen since the pandemic. Further, making everything touchless is the top request for restroom improvements, Alderson notes.

“Today’s touchless handwashing models have never operated better due to new advanced sensing technology that ensures continuous and reliable washing,” he adds. “This new technology makes false activations and misfires an annoyance of the past. Beyond performance, hygiene and convenience, touchless fixtures are easier to keep clean, maintain and service than touch-activated fixtures.”

Efficiency more important than ever

The commercial plumbing market continues to see a growing demand for energy-efficient products and systems, according to Bryan Cordill, director of residential and commercial business development, Propane Education & Research Council (PERC). Most notably, commercial building owners are looking specifically at water and space heating operations, Cordill explains.

Mobile apps, like the Sloan Connect app, wirelessly connects with Sloan restroom products to help facility managers to wirelessly manage settings right from their fingertips.

“Many building owners and operators have a critical need for water heating systems that are reliable, able to meet varying levels of demand, are energy efficient and can fit within a building’s space constraints in order to maintain their business operations,” he says. “As they seek more efficient solutions, we want them to know that propane systems are available and a great fit to offer an innovative, high-performance solution for commercial applications — whether in new construction or as a replacement to an existing system. No matter the size or scope of a building, these systems can provide increased energy efficiency, a smaller carbon footprint, reduced energy costs and better performance compared with other options.”

Water heating accounts for up to a quarter of all energy use in some buildings, Cordill notes. The six largest commercial water heating users include lodging, health care, mercantile, education, food service and office spaces, which, together, account for approximately 85% of all commercial building water heating energy consumption. And Cordill explains that nearly 80% of water heating energy use occurs in buildings built before 2000.

“Newer water heating technology can offer significant improvements in terms of performance and savings,” he adds. “We still are not sure what the occupancy and use of many of our commercial buildings will be, but we know that demonstrating efficiency and cost savings will be critical to winning jobs this year. Owners are concerned about not only the installation cost of the equipment but also the total cost of ownership, life expectancy and operating costs of the equipment. And it’s not just about using less energy, it’s also about lowering the cost of the service. Propane consistently heats water and air at a lower cost compared with electricity.”

Campbell notes efficiency will be more important than ever moving forward in this space.

“There are two major reasons: The first, as always, will be building owners’ and managers’ ongoing efforts to minimize their systems’ operations and maintenance costs,” he says. “The second will be regulations focused on the pursuit of net-zero emissions buildings and the growth of alternative sources of energy, particularly renewables. More and more companies are striving to minimize their carbon footprint, and that trend may accelerate as the public comes to expect those types of ‘green building’ efforts.

“Polypropylene pipe plays exceptionally well in the efficiency space,” Campbell continues. “As a hydrophobic material, polypropylene will never scale or corrode, which means the flow rates for which the system was designed will remain constant over the life of the pipe. The lack of scaling also means the pipe will help the pumps to work at their maximum efficiency, as they will not be working harder to deliver the required flows through piping with an inner diameter narrowed by scale.”

Hortness agrees efficiency will be key.

Bradley’s2020 Healthy Handwashing Survey showed 91% of Americans think it’s important that commercial restrooms be equipped with touchless fixtures, and 90% say their preference for touchless handwashing fixtures has risen since the pandemic. All photos courtesy of Bradley Corp.

“A critical shortage of skilled labor and a renewed focus on quality control has forced contractors to look for smarter, faster, easier and less complex ways to work,” he says. “Efficiency, in terms of both labor and material cost savings, will always be a major driving force. Thermoplastics are generally less expensive and easier to install than alternative materials.

“To this point, we have recently positioned our Xirtec CPVC line of pipe, valves and fittings for use in both hot and cold potable water applications and industrial processes throughout the U.S.,” Hortness adds. “Xirtec CPVC’s excellent thermal properties, superior chemical resistance, and extensive product offering make it an ideal solution for a wide assortment of plumbing projects.”

Efficiency concerns will also continue to be a factor in commercial restrooms, though most of the “low-hanging fruit” has been achieved, according to Lawinger.

“There is still a large population of water wasting products installed and municipalities that have not yet mandated high efficiency products,” he says. “A combination of our weather patterns, governmental requirements and overall awareness of our planet’s declining fresh water resources are driving efficiency. People are growing more aware of the importance of preserving our natural resources so that expectation will continue to grow over time.”

Alderson believes building owners are always looking for ways to minimize their operational and maintenance costs while improving cleanliness, functionality and traffic flow.

“They are looking for operational efficiency,” he says. “In response, commercial restroom manufacturers are incorporating a number of product features to make these spaces run more efficiently, including all-in-one touchless handwashing systems; configure restrooms to avoid wet floors; top fill multi-feed systems; and touchless hand dryers.”

Smart plumbing products on the rise

System integration and controls are key tools for building management and maintenance professionals, according to Cordill “There are several propane tankless water heaters on the market that integrate with these controls, as well as provide remote access for diagnostics and manufacturer support,” he notes. “The goal is to increase up-time and reduce costs for owners.

“As we continue to grapple with climate change, the need for efficient, sustainable products and systems continues to grow,” Cordill adds. “Low-emissions products are especially important for commercial buildings or facilities with environmental standards to maintain or green certifications to reach. Fortunately, propane-powered systems, including water heaters, can support a commercial building’s sustainability goals and offer an environmental impact that aligns with projects requiring green technologies — like LEED certification, for example.”

Lawinger sees smart products continuing to grow in the market over time.

“Connected restroom technology is redefining how facility managers communicate with their plumbing systems,” he explains. “With innovations like the Internet of Things and mobile technology, facility managers are able to maintain connected, user-friendly, and sustainable restrooms right from their fingertips.”

“Smart plumbing products go hand-in-hand with the touchless trend,” Alderson adds. “We expect that there will be more development of these technologies in commercial restrooms. Voice command and IoT are up-and-coming hands-free technologies that have excellent opportunity within restrooms.”

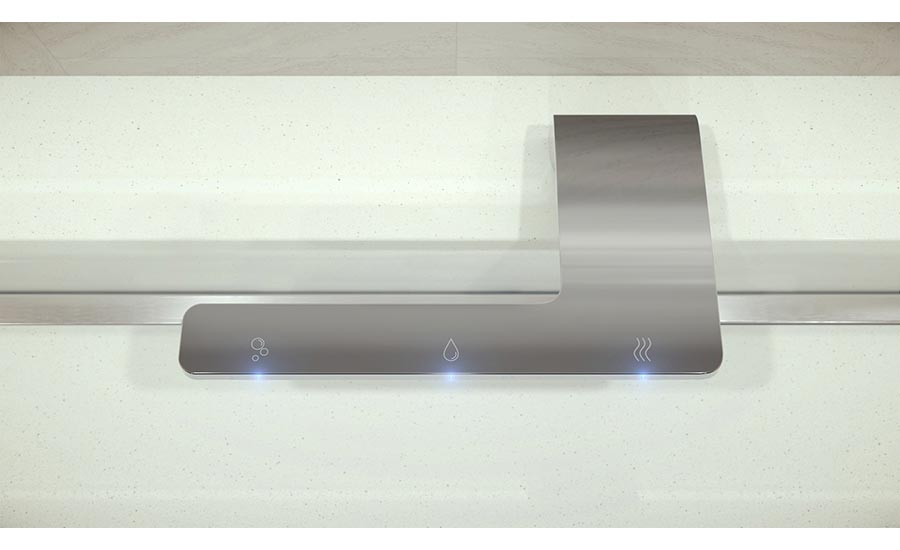

Bradley’s next generation WashBar provides touch-free soap, water and drying in a new floating design for a simple, clean aesthetic. The single connection point to the sink creates more open space for cleaning.

Cleanliness has greatly influenced product design, according to Alderson.

“To improve cleanliness and hygiene in facilities, washbasins are being engineered with self-cleaning functionality,” he says. “For example, Bradley has designed its WashBar with a mechanism to stop germs and bacterial growth in the fixture between uses. The WashBar is programmed to purge water every 24 hours for 5 seconds, if the unit hasn’t been activated within that time. In effect, stagnant water is drained from the piping system and flushed with water to minimize the risk of bacterial growth.”

Though last year was tough on the commercial market and the overall economy, there is light at the end of the tunnel as many economic forecasts are predicting a rebound in 2021, Campbell notes.

“As vaccine distribution moves forward and we emerge into a post-pandemic world, the initiation or resumption of postponed projects could result in a boom in construction in the commercial construction sector,” he says.

As contractors and engineers prepare to resume projects, they should keep in mind these new COVID-19 driven trends.