Outbreaks of Legionnaires Disease continue to be on the rise in the United States according to the Center for Disease Control and Prevention. However, manufacturers of cooling towers — a common source of outbreaks — are attacking the problem at the source with the development of new anti-microbial options.

Legionnaires Disease is a severe form of lung infection caused by exposure to Legionella bacteria. Found naturally in freshwater environments such as lakes and streams, Legionella becomes a health hazard when it grows unabated in water that is not properly treated. In addition to cooling towers, this can include showerheads, hot tubs, public fountains and hot water heaters to name a few.

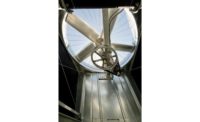

Cooling towers have a long history of effectively expelling heat from the water used in many commercial and industrial applications. However, a recent study from the CDC found that an overwhelming majority of the cooling towers they tested contained Legionella DNA. This indicates that the dangerous bacteria was either currently present or had been at some point, and without proper precautions would eventually give rise to an outbreak.

Legionella bacteria can flourish in cooling towers and spread to humans when expelled water vapor or mist containing the bacteria is inhaled. Each year, as many as 18,000 people are infected with the Legionella bacteria in the United States.

A better mousetrap

As a result, a host of cooling tower manufacturers are releasing new advanced technology to combat the deadly disease. Most notably, this includes cooling towers constructed of anti-microbial resins, which can be fully compounded into HDPE, engineered plastic cooling tower material. The anti-microbial resins contain additives that operate on a cellular level to continuously disrupt and prevent uncontrolled growth of microorganisms and biofilm within the cooling tower.

The anti-microbial material can be compounded into the cooling tower fill (the medium over which the hot water is distributed as it is being cooled), structural casing and sump. This is highly significant because biofilm growth and microorganisms allow a place for bacteria to hide from chemical treatments and also provide nutrients for pathogen growth.

In addition to the material, the cooling tower design can be very significant in the prevention of pathogen growth. Cooling towers designed 20-40 years ago had corners and created pockets where water could stagnate, another condition that can lead to microorganism development. The stagnant water areas are prime breeding grounds for Legionella to grow. To avoid such problems, cooling towers designed today are moving toward a sloped basin and/or basin sweeper system.

Moving forward

While manufactures take steps in the battle with Legionella, ANSI/ASHRAE is also advancing the movement by publishing its Standard 188, Legionellosis: Risk Management for Building Water Systems, which documents new risk standards and requirements for engineers that design new buildings and renovations to existing structures.

The aforementioned standards and requirements do not significantly detail the maintenance practices necessary to keep water systems, such as cooling towers, healthy. However, quality water treatment and accurate monitoring are essential to that effort.

Without consistent, competent water treatment, the Legionella risk is not completely eliminated, even with the new antimicrobial cooling towers. This is due in part to the design of the entire system where inadequate and poor piping can lead to “dead legs,” creating an environment in which pathogens — including Legionella — can thrive.

The best water treatments for Legionella prevention are oxidizing biocides. However, these can react aggressively toward metal surfaces causing excessive corrosion.

Contractors and installers can help reduce outbreaks of Legionnaires by considering the new anti-microbial cooling tower options and by designing water systems where water does not stagnate.

Author bio: Dr. Joseph Kuhl, PhD., is vice president of engineering at Delta Cooling Towers (www.deltacooling.com). Kuhl has a PhD. in Mechanical Engineering from MIT (Massachusetts Institute of Technology) and has more than 25 years of experience working in the HVAC and industrial cooling markets.