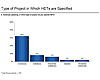

Figure 1.

As green building becomes mainstream, plumbing engineers increasingly specify water-conservation fixtures such as high-efficiency toilets, or so we assume. To find out for sure,pmeconducted an extensive survey of our readers to find out how much influence they really have to recommend or specify HETs.

HET History

The first HETs were dual-flush water closets (for liquid or solids) that appeared in the American marketplace in the 1990s. An Australian company made one model; a Swiss company made another.Today, several water closet manufacturers produce nearly 100 HET models, either low flush or dual flush. Typically, the dual-flush units dispense 0.8 gallons to flush liquid waste and 1.6 gallons to flush solid waste.

All HETs meet the performance requirements outlined in ASME A.112.19.2, which is to flush at a maximum of 1.28 gpf while achieving a MaP test score of removing at least 350 grams of waste. At 1.28 gpf, HETs use 20% less water than the 1.6-gpf water closet, which first hit the market in 1994 and represented a 50%+ reduction of water usage from the 3.5 gallons previously used in toilet design.

The impetus for the 1.6-gpf water closet was the 1992 Federal EPAct, which mandated that, as of Jan. 1, 1997, the majority of all commercial water closets manufactured for sale in the United States be designed to flush using no more than this amount of water.

The EPA’s WaterSense program, which began in June 2006, considers HETs to be “water friendly,” too. According to the EPA, toilets account for about 30% of indoor water use in the home. The agency estimates that if all inefficient U.S. water closets were replaced with WaterSense-labeled HETs, the country would save nearly 2 billion gallons of water per day.

We sent questionnaires to more than 3,500 readers and 7% responded, which is an excellent response rate. Usually, a response of 3% is considered to be very successful.

This survey encompasses 16 questions in four sections. Section 1 focuses on frequency, project preference and personal influence when specifying HETs; Section 2 on LEED concerns; Section 3 on the overall role of HETs in your water-conservation efforts; and Section 4 on manufacturer influence.

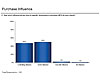

Figure 2.

Engineer Influence

Section 1 includes five questions. The first question is: When designing a water distribution system, do you specify high-efficiency toilets? More than 70% of those responding gave an affirmative answer. This very high response is even higher than we anticipated.For those who specify HETs, we wanted to know how often they do so. Based on our survey, 48% of readers (Figure 1) specify them most of the time. The next most popular choice is always (29%) followed by sometimes (20%) and rarely (3%).

Question 3 asks: Which type of HETs do you primarily specify? According to our survey, more than half of readers primarily specify HETs with a dual-flush device (52%), and less than half specify them without a dual-flush device (48%).

Next we wanted to know the types of projects where readers specify HETs (Figure 2). Nearly two-thirds of respondents (64%) say commercial projects. This percentage is the largest, followed by institutional (16%), residential/multifamily (12%), industrial (4%) and residential/hotel-motel (4%).

To close out Section 1, we inquired: How much influence do you have to specify, recommend or purchase HETs for your clients (Figure 3)? A whopping 97% selected either “some influence” (50%) or “controlling influence” (47%). Only 3% say they have either very little or no influence.

Figure 3.

Following LEED

The three questions in Section 2 focus on LEED concerns. Question 6 asks: Do you follow the LEED program? An impressive 84% say they do. Then come two follow-up questions: Which version of LEED do you follow? Are you a LEED Accredited Professional? Nearly two-thirds of respondents (64%) say they follow version 3.0, while 36% follow an earlier version. Inversely, just one-third (33%) say they are a LEED-AP.

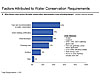

Figure 4.

Water-Conservation Efforts

In Section 3, the focus shifts to the role of HETs in overall water-conservation efforts. First we ask, What factors most control the water-conservation requirements in your plumbing design (Figure 4)? Multiple responses are allowed. More than half (52%) say their own recommendation on water conservation is the main factor. Not far behind are green building certification (39%), owner/developer (38%) and plumbing code (31%). Architect concerns (16%) and other (4%) close out the replies.The next question is: How significant a role do HETs play in your designs as a way to gain green building certification (Figure 5)? We gave four options, and readers responded as follows: somewhat significant (48%), very significant (42%), somewhat insignificant (6%) and very insignificant (5%).

Figure 5.

At this point, two detailed questions relate to HETs. First we ask about the importance of four performance factors when specifying an HET: flushing, bowl clearing, drainline carry test and amount of noise produced during flushing.

Let’s look at each factor separately. Regarding flushing performance, 89% feel it is important but 4% don’t. The numbers for bowl clearing (87% vs. 6%) and drainline carry test (81% vs. 9%) are comparable. Only 44% feel the amount of noise produced during flushing is important; 24% say it isn’t important and 32% say it is a neutral issue.

We then ask readers a specific design question: When designing a drainage/waste/vent system for an HET, how often do you increase the number of toilets discharging to a 3-inch drain to the maximum number permitted by code? Sometimes is the most popular answer with 28%, followed closely by most of the time (23%) and never (22%). Less popular are rarely (14%) and always (13%).

Figure 6.

Manufacturer Influence

To close the survey, we ask three questions to find out how much (or little) influence manufacturers have on plumbing engineers’ specifying decisions regarding HETs. Based on responses to questions 14 and 15, manufacturers have a significant influence. A large percentage of readers (84%) say they specify HETs by manufacturer and/or model number. Of this total, 90% do so by manufacturerandmodel number. Only about 10% do so by manufacturer (9%)ormodel number (2%).Finally, we wanted to know if there are certain brands of HETs that you wouldn’t specifybased on your knowledge of their flushing performance. The result is close to what we expected, as a strong majority (56%) say no. Engineers know that flushing performance of HETs is good and getting better.

If you received the survey questionnaire and responded, we thank you for your help. If you did not receive a questionnaire, keep an eye on your e-mail for our next survey. When you get it, take a few minutes to fill it out and send it in. You can help contribute to our next article.