While researching the Philadelphia Single Stack system for this article, I frequently came upon the name of Joseph Smaul, P.E. Who was Joseph Smaul? In the ASPE Chapter/Philadelphia engineering world, Joe was the “Philly Single Stack” guy. He designed, built and taught the single stack for more than 50 years. Unfortunately, Joe passed away suddenly this past summer and is greatly missed by the ASPE community.

For the technical content of this article, I’ve decided to remember Joe by presenting some edited segments from an Aug. 2003 article he wrote forpmetitled, “Hotel/Motel Plumbing Utilizing the Philadelphia Single Stack System.”

Overview. The single stack, also commonly known as a wet vent system, is based on the theory that the drain lines will be of sufficient size to accommodate the three factors involved in any drainage system: solids, liquids and air. The single stack system used in Philadelphia was developed based on this theory.

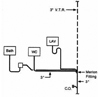

Drawing 1.

Plumbing Engineer Benefits & Basic Design

What is the main benefit that this system offers plumbing engineers? Without a doubt, the answer is cost-effective installation. Let me explain why.First, the Philadelphia single stack plumbing system does not require, nor does it depend on, any special type of drainage or vent fitting.Any conventional type of drainage or vent fitting - such as a merion fitting, combination wye and 1/8 bend (single or double), sanitary tee (single or double), taped sanitary tee (single or double), long 1/4 bend with or without tapings, etc. - is permitted, as long as that particular material is in compliance with the Philadelphia Plumbing Code.

In fact, there is a no-hub cast iron soil pipe manufacturer that makes a fitting that they have named “The Hub-less Philadelphia Single Stack Fitting.” This fitting is available in several configurations, such as having two 4" outlets opposite each other - with the option of having four 1-1/2" outlets, two on each side, opposite each other. Having such a variety of fittings available only increases the flexibility and cost reduction of the installation in multi-story buildings. There are no restrictions regarding the levels at which small-fixture waste lines enter the soil or waste stack, as long as the fittings in the stack are drainage fittings and are acceptable in accordance with the code.

Second, fixtures (other than toilets) that are no more than 12 feet distance from the waste stack are allowed to be connected without additional venting. This potential reduction of vent pipe is a great economical benefit as well as one less field coordination item. A water closet may be up to eight feet from a vented stack or vented horizontal main without requiring an additional vent.

In the case where the outlet of a floor-mounted water closet is not more than four feet from the stack, you may use a long 1/4 bend with two 1-1/2" tapped outlets. The outlets can be used to connect a lavatory and a tub if they are within 12 feet and will not require an additional vent. You also have the option of utilizing the other fittings noted (see drawing). Because additional venting is not required, the flexibility this system offers can often result in installation cost savings of up to 40% in multi-story buildings such as hotels and apartments.

When plumbing fixtures are installed beyond code limitations, such as eight feet for a water closet or 12 feet for other types of plumbing fixtures, or when a horizontal branch line has more than one plumbing fixture connected to it, a vent is required. Materials for vent piping are the same as for drainage piping. Vent pipe sizing is determined by the vent length and the number of DFUs connected.

Third, it allows rather simple sizing of the sanitary stack system.Design the sanitary system connecting all the horizontal branch lines (in a multi-story building) to the vertical sanitary stacks. The stacks continue down through the building to the lowest level and connect to the horizontal main drain, located at the ceiling of the basement or under the first floor slab. All pipes are sized by adding the total number of drainage fixture units assigned to each individual plumbing fixture connected to each horizontal branch line, which in turn is connected to each stack.

The stack size is dependent upon the total number of drainage fixture units that are connected to it and extends full size up through the building. So, if the total number of drainage fixture units requires an 8” stack, then that stack is eight inches up through the building, and it becomes an 8" vent above the highest plumbing fixture and continues up through the roof.

If a building is 75 feet in height and not more than 160 feet in height above grade level at the curb, the vertical soil or waste stacks connected to the house drain or to any of its branches shall be one size larger; should the building height exceed 160 feet, then the stack shall be increased two sizes. The horizontal main drain may increase in size as each vertical stack is connected (counting the connected DFUs).

When the building is more than three stories high, all plumbing fixtures on the first floor are connected to the horizontal main drain and not the vertical stack. This is done to prevent hydraulic jump, which, in turn, would pull the water seal in the plumbing fixture trap.

Fourth, its cost-effectiveness for single-story buildings.When designing for a one-story building, the main horizontal sanitary should be located within the proper distance of the plumbing fixtures to eliminate additional venting. In this instance, we calculate the size of the main starting from the last plumbing fixture connections and increase the size of the main drain when additional fixtures are connected. The size of all horizontal sanitary drainage pipe is determined by two factors: 1) the total number of DFUs, and 2) the slope of the pipe.

If the last set of plumbing fixtures is a bathroom group, the vent for the main house drain could be a 4" pipe, even though the main sanitary drain may be an 8" line. This holds true as long as all of the plumbing fixtures are within the allowable distance of the sanitary stack.(Note: No additional venting is required under this condition.)If the plumbing fixtures are beyond the allowable distance, or when a horizontal branch line has more than one plumbing fixture connected to it, a vent is required.

Any single water closet or pedestal urinal branch more than eight feet in length or any single waste branch for fixtures other than water closets or pedestal urinals more than 12 feet in length shall have a vent sized at least one-half the diameter of the branch pipe. Every branch, horizontal soil pipe, or waste pipe to which a group of two or more fixtures is to be connected shall have a vent of the same size as the branch.

In addition, a vent stack or main vent shall be installed with a soil or waste stack when relief vents or other branch vents are required in more than five branch intervals. Vent sizing is similar to other model codes based on DFUs connected and length of vent.

To read the “Point” perspective of this month’sPoint/Counterpointarticle on Single-Stack Systems for High-Rise Buildings,click here.