AA-size water hammer arresters are now sweeping the country as the permanent and affordable solution to that age-old problem of banging pipes and system damage caused by water hammer pressure surges, but this progress has been a long time in the making. Like many things in our industry, change doesn't happen overnight. Process and product innovation, industry education, along with new product standards and codes, have led the way.

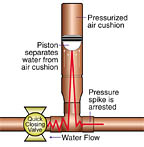

For decades, most plumbing engineers have seen the need to control water hammer and have specified engineered water hammer arresters in commercial plumbing systems for this purpose. An engineered arrester employs a compressible cushion of air or gas that allows the non-compressible flowing water to be displaced in its chamber, rather than stop abruptly. Arresters are also designed to permanently maintain their pressure charge.

There are various designs on the market, but most arresters today employ the piston design to accomplish this. Two o-rings on the piston allow it to float up and down the lubricated walls of the arrester barrel, absorbing water hammer, without losing its pressure seal, even after thousands of cycles. Large multi-fixture arresters have been commonly produced for many years in six commercial sizes generically classified as Sizes A through F. The American Society of Sanitary Engineering lists these generic size categories in their ASSE 1010-96 Arrester Standard. ANSI recognizes this standard as well as the ANSI/ASSE 1010-98 Standard in place of their obsolete A112.26.1M.

In the 1980s, several arrester manufacturers offered a better alternative to plain air chambers when they introduced their single-fixture size arresters to the marketplace. At first, the use of these new arresters was somewhat limited due to the lack of official recognition at the codes and standards level. That all changed in 1996 when ASSE officially added the single-fixture AA-size category to the other six A through F arrester sizes in their ASSE 1010 Standard. Within 12 months, no less than three manufacturers had received ASSE certification on their compact and more affordable AA sizes, or Double-A arresters, as they are now called.

Since then, the installation of AA arresters to control water hammer has grown tremendously throughout the country. Code officials in many states see the AA arrester as a very simple, very feasible way to address this water hammer control issue they've been struggling with for years. And not surprisingly, a large number of plumbing contractors report they are installing AA arresters even on applications where they are not required by code. They say arresters add quality to their jobs and help reduce callbacks.

The compact AA arrester is essentially just like its larger A through F multi-fixture size counterparts, employing the piston design. The combination of its design simplicity and the soaring usage of AA arresters has allowed arrester manufacturers to take advantage of the latest advances in production automation and quality inspection. Thus, production costs are reduced while still maintaining high quality.

The AA size is considered a single-fixture arrester with a fixture-unit rating of 4, and it is designed for installation on a plumbing faucet or fixture at the point of use. In other words, one AA arrester should be placed on both the hot and cold lines as close as possible to each culprit valve or faucet that causes hammer.

Don't be confused by the many different connection options offered with the AA arresters for various applications. The AA size arrester is just that, AA size, whether it has a 1? MIP connection or a 3? hose thread tee connection. Unlike other plumbing products, arrester capacity sizes are not determined by their fitting connection size. The various connection options are simply for the convenience of the installer.

A common myth is that one large arrester centrally located will control hammer throughout the piping system. In reality, this does little or nothing to control hammer. The arrester loses its effectiveness the farther away from the valve it is installed. Installation within six feet of the valve may work fine. However, when the arrester is installed 20 or 30 feet away, it has little effect. Arresters work like shock absorbers on a car. Your car has four wheels, so you need no less than four shocks, one placed at each wheel (point of use). Imagine the damage and abuse your car would take if it didn't have four properly placed shock absorbers. Your plumbing system is subject to the same type of abuse without proper arrester installation and placement.

Another question often asked is whether arresters are necessary on plastic tubing. Water hammer is a concern regardless of piping material, metal or plastic. It may be true that plastic tube does not seem to transmit as much noise as copper, but the energy from the flowing water is still there. It has to go somewhere. As a matter of fact, plastic tubing has a slightly smaller inner diameter compared to the same nominal size copper, so the flowing water has a higher velocity, which means even more energy to be absorbed when the flow is stopped. Upon valve closure, plastic tubing expands minutely which does absorb a small amount of this energy, but water hammer can still occur at flow rates of three or four gallons per minute. Many contractors install arresters on plastic tubing systems to alleviate the tubing and joints of any undue stress and strain, rather than the plastic system taking the full brunt of the pressure surge all by itself.

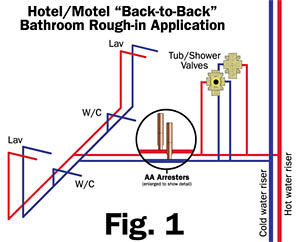

Even though the AA size is often thought of as residential, it can certainly be specified for commercial projects as well. Its ASSE listing and fixture-unit rating of 4 makes it ideal for sizing and specification on projects such as hotels, motels, or multi-family.

For example, a common mistake in hotel arrester sizing and placement is specifying one large multi-fixture arrester centrally located between several rooms. Worse yet, sometimes one arrester is specified to cover an entire floor. No matter how large the arrester is, the centrally located placement will not suffice. Large multi-fixture arresters work great on a commercial restroom with a bank of fixtures all on the same header; but when the branch lines go off in many directions, like in a hotel, smaller arresters placed at the point of use would be a better solution.

To insure proper water hammer control on this type of project, specify a pair of AA arresters at each tub/shower valve (a common water hammer culprit). For the typical hotel back-to-back bathroom configuration, one pair of AAs will suffice for both valves (Figure 1) since the chance of simultaneous shut-off of both valves is almost nil.

The product innovation of AA arresters has created dramatic effects at the code level as well. In the past five years, there have been major code revisions concerning water hammer control. In 1996, IAPMO published its UPC Installation Standard IS 20-96 for CPVC piping systems, which required arresters on all solenoid valves supplied with CPVC tubing. When this was first published, the UPC had yet to require arresters on other piping materials.

Then in 1997, IAPMO added Section 609.10 Water Hammer Control to the main body of the Uniform Plumbing Code, and then updated it in the UPC-2000 revision. This section calls out the requirement of either listed mechanical devices or air chambers on all quick closing valves in all potable water systems. It does not make exceptions for any piping material?PVC, copper, PEX or otherwise. Because of this new water hammer control requirement covering all piping systems, including CPVC, the secondary reference to water hammer control in the CPVC Installation Standard was deleted in 1998, evidently due to redundancy.

UPC's definition of listed mechanical devices can basically be interpreted as a UPC-listed AA arrester. UPC Table 6-6 calls out the air chamber requirements, which lists some very large-sized air chambers indeed. In addition, the section also requires each one of these air chambers to have their own means of drain down and air replenishment. The common sized 12" plain air chambers do not satisfy the requirements of this code. To my knowledge, the UPC-listed AA arresters are by far the contractors' choice to fulfill the requirements of this UPC water hammer control section.

The International Plumbing Code (IPC-2000) also has a very similar requirement for water hammer control in its Section 604.9. AA arresters conforming to the ASSE 1010 Standard fulfill the product requirements of this code as well. IPC states that arresters should be installed per manufacturer's instructions. Therefore, if the arrester manufacturer states its arrester can be installed without access, then no access panels are required. Several states are already enforcing this section, and other states are planning to do so this year.

The story of the AA arrester is a good example of industry demand, research and development, production innovation, and all the people associated with the code development process striving together to come up with a quality solution to water hammer that is affordable enough to be considered for any and all plumbing systems.