Editor's Note: This article was reprinted from the published technical proceedings of the 1999 CIB W62 Symposium on Water Supply and Drainage for Buildings held in Edinburgh, Scotland.

Abstract

This paper examines the development of the two-button, dual flush water closet technology concept in Australia to meet economic, market and environmental objectives. Particular emphasis will be given to the extensive investigation and development period that led to the introduction of the 6/3-litre (1.6/0.8-gal) dual flush system. The investigation involved w.c. performance evaluation at varying grades in 40 metres (131 feet) of transparent 100 mm drainage pipe conducted by the Brisbane City Council in Queensland, Australia.

Results from the Brisbane trial showed that the 6/3-litre (1.6/0.8-gal) dual flush w.c. system provided a savings of about 60% compared with the then-standard 11-litre (2.9-gal) full flush system with no adverse effects on the performance of the drainage pipe. At this time and pending the results of further field trial, an industry directive was issued by the Water Authorities that the 6/3-litre (1.6/0.8-gal) dual flush system would be implemented no later than January 1993. During the above development period, the w.c. designs were progressively refined together with the development of new performance-based standards, namely AS1172-1 Pans and AS1172-2 Cisterns (1993), with the latter based on the trial results. Over the past six years, the development of sound performance requirements and extensive trialing have validated this w.c. system in the Australian marketplace. Importantly, the significant water saving benefits of the 6/3-litre (1.6/0.8-gal) dual flush w.c. technology have now been fully verified and passed on to the community.

Background

Water conservation is a vital issue on a global scale. This is particularly the case in Australia, the second driest continent on Earth, with over 70% of the land surface desert or semi-desert. Australians have been brought up to experience periodic water shortages and restrictions in all major capital cities, together with regular severe droughts in rural areas due to unreliable rainfall patterns. Culturally, Australians have a deep-rooted appreciation of the need to conserve water and have shown a willingness to accept the introduction into the marketplace of bathroom appliances that are environmentally and socially responsible.In view of the mentioned cultural and environmental influences, it might be expected that, historically, the w.c. flush volumes in Australia would have been lower when compared to other Western countries. However, this has not been the case. As a matter of record, water consumption from bathroom appliances was not a major issue in Australia until the late 1970s. The need to reduce bathroom water usage has been driven mainly by water authorities and governments.

The two-button, dual flush w.c. technology was developed after receiving an Australian government industry grant which led to a number of refinements and ultimately the development of the reduced flush 6/3-litre (1.6/0.8-gal) system. The impact of this technology on water consumption has been truly significant. The water reduction/conservation effects of the combination of the two-button dual flush technology and reduced flush volumes in Australia are shown in Figure 1. (Figure 1 could not be reproduced online. Please see print edition.) Theoretically, water consumption (litres [gals] per person per day) has been reduced from 55 litres (14.5 gals) in 1982 to 18 litres (4.8 gals) in 1993.(1)

The development of the 6/3-litre (1.6/0.8-gal) dual flush system will now be discussed with reference to the trial period, along with design and development aspects of this w.c. system.

The Two-Button Dual flush Concept

The dual flush principle or concept (which aims to reduce w.c. water usage by providing two flush modes) is not new. This concept is comprised of a full flush to remove solids and paper, and a reduced flush to remove urine. Cisterns were available in the Australian marketplace with this capability prior to 1980, but they had received very limited public acceptance, due mainly to user operational complications. Such systems have required the user to activate each flush mode with two different operations. Normally the reduced flush mode was controlled with a normal pushbutton operation while the full flush required the user to hold the pushbutton down until the flush cycle had been completed. Problems were experienced with the full flush cycle when the button was not held down, thus preventing the complete volume of water to discharge and properly cleanse the w.c. pan.

An innovative design approach was used in the development of the original two-button dual flush concept in order to overcome these user problems. The development program focused on the simplification of operational aspects of the outlet valve mechanism employing two buttons. A fundamental design consideration was for the flush mechanism to be simple and straightforward in operation, while appealing to users who, given the choice, would act responsibly to conserve water.

Water Authority Field Trials

During the mid-1980s, the Australian Water Authorities established the Water Efficient Appliances and Plumbing Group (WEAP) responsible for encouraging the reduction in water usage of bathroom appliances. It was shown that the humble w.c. used an average of 32% of the in-house water consumption(2) and was thus seen to offer the potential for reductions in flush volumes. This view was supported by the realization that 6-litre (1.6-gal) reduced flush systems were being used overseas.From a WEAP initiative in 1986, the Brisbane City Council conducted a study termed "Investigation of reduced flushing volumes in sewer systems." Caroma Industries participated in the investigation with the development and supply of five flush volume options for the trial. Following the market acceptance and water saving benefits of the 11/5.5-litre (2.9/1.5-gal) two-button system, it was considered logical to include four reduced flush dual flush options in the investigation, including a 6/3-litre (1.6/0.8-gal) dual flush w.c. version. The aim of this investigation was to establish the most effective low flush capacity and the associated potential water savings of each of the noted flush options.

The related experimental work was conducted with respect to operation of a w.c. and drain/sewer line transporting human excreta and other wastes. The behavioral characteristics of the latter were observed in a 40-metre (131-foot) long, transparent 100 mm sewer line laid at grades of 1 in 40 (2.5%) and 1 in 60 (1.65%). It should be noted that in Australia, the minimum grade in building drain networks is 1 in 60 (1.65%).(3)

During periodic inspections of the transparent sewer line, it was observed that 11-litre (2.9-gal) and 9-litre (2.4-gal) single flush and dual flush systems fully cleared solids and paper from the sewer with each operation. In the case of the 6/3-litre (1.6/0.8-gal) and the 5/2.5-litre (1.3/0.7-gal) dual flush systems, regular settling of solids was observed, which were cleared from the sewer with subsequent 3-litre (0.8-gal) and 2.5-litre (0.7-gal) half-flushes, respectively.(4)

The overall results of the investigation confirmed the water saving potential of the 6/3-litre (1.6/0.8-gal) dual flush system, and also established that it was as effective in clearing solids from the sewer as the 11-litre (2.9-gal) cistern. These water savings are summarized in Table 1.

Table 1. Water saving results from the trial of nominated flush options.

Flush Volume Water Savings

11-litre (2.9-gal) full flush Standard

9-litre (2.4-gal) full flush 18.18%

11/5.5-litre (2.9/1.5-gal) dual flush 26.09%

9/4.5-litre (2.4/1.2-gal) dual flush 39.56%

7.5/3-litre (2/0.8 gal) dual flush 53.22%

6/3-litre (1.6/0.8-gal) dual flush 59.71% (~60%)

5/2.5-litre (1.3/0.7-gal) dual flush 66.39%

Based on the above investigation results, a recommendation was made by the Standing Committee Plumbing and Drainage for the implementation of the 6/3-litre (1.6/0.8-gal) dual flush cisterns and matching pans in new installations no later than January 1993. The heads of the major water authorities in Australia adopted this recommendation pending the results of further trials in their respective sewer systems.

The authority evaluation trials that followed in sewer systems were very extensive, involving 223 sites over three towns in Western Australia. Together with trials in Melbourne and Brisbane, these trials confirmed the earlier results from the Brisbane City Council investigation. Reticulation sewers were also inspected and surveyed for blockages and defects by closed circuit TV. Significantly, the trials in Western Australia verified that the average per-flush-volume of the 6/3-litre (1.6/0.8-gal) dual flush system was 3.8 litres (1 gal) against the theoretical volume of 3.6 litres (0.9 gals).

6/3-litre (1.6/0.8-gal) Dual Flush Development

The sanitary-ware industry in Australia, over a seven-year period leading up to 1993, completely redeveloped its w.c. ranges to incorporate the 6/3-litre (1.6/0.8-gal) technology. An iterative design and development process was used to product w.c. concepts along the following lines. Conceptual design work was produced initially in prototype form in the laboratory for subsequent validation in live field trials. Information gained in the field influenced design refinements, which improved the performance of the w.c. and drainage network. This design-test and re-design iterative approach was repeated many times until a satisfactory final design outcome was achieved and validated empirically. The design process was complicated by the necessity for the w.c. to function in compliance with the performance requirements of the half and full flush volumes.In view of the influence of the 3-litre (0.8-gal) half flush volume on the potential water savings of the w.c., it was imperative that user expectations for the removal of urine and paper were clearly satisfied. User trials were instrumental in progressing the development of a successful w.c. design. Regular inspections of trial installations, together with householder discussions and questionnaires, were used to gain the necessary feedback for making design improvements. A number of key w.c. design criteria were identified from the analysis and evaluation of user feedback. These were fully addressed during the iterative development of trial prototype w.c.s, and most importantly, in the final commercial models developed. Six key design criteria (and related design specification issues) were identified from these user trials, namely:

- Maximize sump water area.

- Minimize sump volume.

- Maximize trap through-way section.

- Optimize the performance of the rim and bowl configuration.

- Maximize the flow velocity from the cistern to the pan.

- Ensure operational reliability of the dual flush valve mechanism.

- Design must be cost-effective for all market segments.

To meet these criteria, the dual flush outlet valve mechanism was completely redesigned. A new knock down float principle was developed that, once activated, would close the valve by means of prematurely knocking down the interflow tube once the flush volume had discharged from the cistern. The full flush cycle operated normally as the knockdown float was held in a disengaged position with a lever. Both the full and half flush w.c. mode functions are illustrated in Figure 2.

Key Design and Development Issues

Mindful of the major commercial risks involved with such a large-scale development, relevant key issues were identified and fully addressed during the design and development period. These issues were environmental factors, water saving potential, user acceptance, governmental issues and public health. Failure to properly address any of these issues would have adversely affected the water saving benefits and the commercial viability of the 6/3-litre (1.6/0.8-gal) dual flush system in the Australian marketplace.(5)

Standards

Australian Standards AS1172 Part 1, Pans, and Part 2, Cisterns (1993), were developed during the latter part of the trial period (i.e. from 1990). These standards are mainly performance based, with the exception of the water seal requirement height. A half-flush-toilet paper discharge test and a Solids test (6) were two new performance tests included in the pan standard. It was deemed necessary for the w.c. to be able to remove toilet paper with the 3-litre (0.8-gal) half flush cycle to ensure that the water savings were optimized.It was also necessary to include a solids test in the standard to cater for major concerns about the influence of reduced w.c. flush volumes on the human waste carrying characteristics in sewers. This test was established to ensure that the pan would meet minimum performance requirements in discharging solids from the outlet and through the drainage network. Proven DIN 1385 performance tests were adopted here with only small modifications. The requirement of this standard test is for all four artificial feces to be flushed from the pan outlet with a minimum of 2.5 litres (0.7 gals) behind the last solid to leave the pan.

The w.c. prototypes developed during the trials were designed to meet these design criteria/performance requirements. Test results verified the relevance of the tests as instruments to evaluate the overall performance of a w.c., as well as being useful in the evaluation of user acceptance.

During the drafting of the mentioned standards, based around the 6/3-litre (1.6/0.8-gal) dual flush system, the technical committee ensured that other flushing technology (of a proven water usage equivalent to the 6/3-litre (1.6/0.8-gal) dual flush system) would not be precluded from compliance with the standards. The proven single flush equivalent to the 6/3-litre (1.6/0.8-gal) dual flush system is 3.6 to 4.0 litres (0.9 to 1.1 gals).

Water Saving Potential

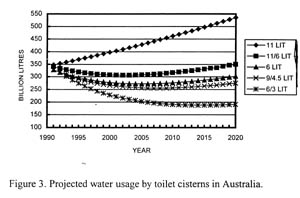

One of the exciting outcomes of this kind of design and development work is of course the potential for a new system to achieve major savings in water consumption while satisfying the other issues and criteria noted earlier. In this respect, theoretical studies were conducted in 1991 to simulate the estimated projected water savings in Australia over time of a 6/3-litre (1.6/0.8-gal) dual flush system compared to other flushing volumes.The following information was used in the study to determine data for constructing the graphs shown in Figure 3:

- Total population.

- Projected population.

- Total households.

- Projected number of households.

- Number of toilets per household.

- Flush volumes in current use.

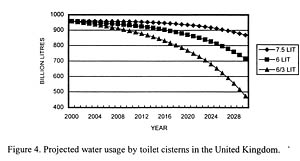

It has been found that these simple graphs are a very effective way to simulate or represent the potential water savings of utilizing the 6/3-litre (1.6/0.8-gal) dual flush system compared to other systems. Dr. P.J. Cooke from the School of Mathematics, University of New South Wales, prepared the Unisearch studies conducted for the senior author. A number of studies for various countries have since been conducted, including an interesting one for the United Kingdom which is shown with graphical projections in Figure 4.

The chart of the data from the study in Figure 3 clearly showed that, for Australia, the amount of water being used in the year 2020 was anticipated to be less than the amount being used in 1991. This result was achieved even with a projected population increase to 26,707,000.

As in the case of the Australian study, the graph for the UK (Figure 4) shows the substantial water savings theoretically possible with the use of the 6/3-litre (1.6/0.8-gal) dual flush system compared to the 7.5- and 6-litre (gal) options. In the study it was assumed that after the year 2000, all new and replacement cisterns would be 6-litre (1.6-gal) single flush or 6/3-litre (1.6/0.8-gal) dual flush systems.

To put the water savings figures in context, Water UK quoted that water supplied per year by water companies in the UK was 7117.5 billion litres (1.9 quadrillion gals). From the data, the projected water savings by the 6/3-litre (1.6/0.8-gal) dual flush system were shown to be 396 billion litres (104.6 trillion gals), while the water savings for the 6-litre (1.6-gal) single flush system was 152 billion litres (40.2 trillion gals). A water savings of 396 billion litres (104.6 trillion gals) or 5.56% of total water supplied annually (using current figures) will not only conserve water but will also reduce the volume of w.c. waste water to be treated.

These charts clearly illustrate the potential savings in water consumption which may be achieved when low-volume, dual flush w.c. technology is adopted on a statewide or national basis over an extended period of time. In Australia, the widespread adoption of this technology has conserved precious fresh water reserves and no doubt delayed the construction of costly new reservoirs and sewerage treatment works. Given an Australian population of about 18 million, the water savings have indeed been immense.

Conclusion

This paper has traced the development of low-volume, dual flush w.c. technology in Australia with due regard to the two-button design concept, water authority field trials, the development of the 6/3-litre (1.6/0.8-gal) dual flush system, the key design and development issues, standards and the water saving potential of this innovation.Unique cooperation has occurred between private industry, the state and national water authorities, and most importantly, the consumers/users. Australia now benefits from the lowest (maximum) flush volume requirements in the world for water closets that can be directly connected to a standard sewer system. The performance of this dual flush technology system has been verified in the Australian marketplace, where it is now completely accepted.

This paper has also demonstrated the value of conducting user trials concurrently with an iterative design and development process--that is, from the earliest conceptual stage right through to the development of prototypes and on to the final commercial introduction of the product. Therefore, the water saving benefits of the system have been fully validated. There is little doubt that the wide adoption of this w.c. concept has realized savings of billions of litres of water annually.

The design and development of w.c.s that are simple in operation and which appeal to users has been shown to be fundamental to the market success of the two-button dual flush system.

Comprehensive field trials of w.c. concepts have provided a databank of vital design information, which has led to a much better understanding of the manufacturer/consumer relationship.

It is worth noting that there is still substantial scope for further reductions in water consumption with the use of 6/3-litre (1.6/0.8-gal) dual flush systems.