Issue: 10/04

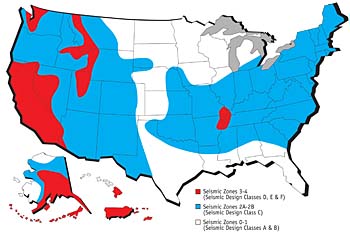

More than 80% of the states in the U.S. are adopting the International Building Code (IBC) that addresses, among other things, the installation of fire sprinkler systems in seismic zones. Engineers and specifiers will need to be aware of these requirements and how best to meet them.

Briefly, the code is intended to neutralize the probability of fire sprinkler systems being damaged and made inoperable by seismic activity, including ceiling movement that can shear sprinkler heads and/or disrupt the integrity of armover connections to branch lines or mains. An in-depth study of the performance of fire sprinkler systems during the 1994 Northridge earthquake influenced many of the standards (Analysis of Fire Sprinkler System Performance in the Northridge Earthquake, Russell Fleming, NFPA, National Institute of Standards Publication NIST-GCR-98-736.) The study found that a common mode of failure was the breaking of threads at the tops of drops to sprinklers penetrating a substantial ceiling. These failures occurred from sprinklers and ceilings moving at different frequencies, shearing sprinklers and fitting threads.

In general, depending on the seismic zone rating of the building location, the codes direct either 0.25-inch (6 mm) or 1-inch (25 mm) minimum horizontal clearance on all sides of the sprinkler head to accommodate movement between the suspended ceiling and the sprinkler head during a seismic event.

The objective, of course, is to maintain the ability of the sprinkler system to deal with post-earthquake fire hazards, as well as to prevent the significant water damage that can occur from sprinkler-system ruptures in an otherwise undamaged building. Factory Mutual, for example, reported that just three of the earthquakes that occurred between 1987 and 1994 caused 144 sprinkler leakage losses covered by FM. The average loss was $212,000, for a gross total of $30 million in 1995. Both the safety and the economic incentives are obvious.

The IBC Code and Sprinkler Design in Suspended Ceilings

There are two main seismic design categories that need to be considered: Seismic Design Category C, which consists of formerly identified seismic Zones 2A and 2B, and Seismic Design Categories D, E, and F, which consist of formerly identified seismic Zones 3 and 4. In Seismic Design Category C, suspended ceilings are designed and installed in accordance with Ceilings & Interior Systems Construction Association (CISCA) recommendations for Zones 0-2. Sprinkler heads and other penetrations shall have a minimum of 1/4-inch (6 mm) clearance on all sides.In Seismic Design Categories D, E, and F, suspended ceilings are designed and installed in accordance with the CISCA recommendations for seismic Zones 3-4, with some additional requirements. The additional requirements include using a heavy-duty T-bar grid system, providing a 3/4-inch clearance from the closure angle of the grid system and providing a horizontal restraint of the ceiling to the structural system. Rigid braces are permitted to be used instead of diagonal splay wires. Braces and attachments to the structural system above shall be adequate to limit relative lateral deflections.

Except where rigid braces are used to limit lateral deflections, sprinkler heads and other penetrations shall have a 2 in. (50 mm) oversize ring, sleeve, or adapter through the ceiling tile to allow for free movement of at least 1 in. (25 mm) in all horizontal directions. Alternatively, a swing joint that can accommodate 1 in. (25 mm) of ceiling movement in all horizontal directions is permitted to be provided at the top of the sprinkler head extension.

As an alternative to providing large clearances around sprinkler system penetrations through ceiling systems, the sprinkler system and ceiling grid are permitted to be designed and tied together as an integral unit. Such a design shall consider the mass and flexibility of all elements involved, including ceiling system, sprinkler systems, light fixtures and mechanical appurtenances. The design must be performed by a registered design professional.

Swing Joints

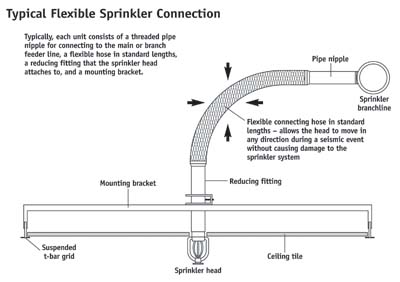

Flexible fire sprinkler connections provide characteristics that exceed the most stringent seismic code requirements. The typical flexible fire sprinkler connection includes a mounting bracket that attaches to the suspended ceiling grid, and a corrugated stainless steel hose reinforced with a stainless steel braid that provides a flexible connection from the branch line to the ceiling penetration. The flexibility of the hose allows the head to move in any direction during a seismic event without causing damage to the sprinkler system. Note that a typical swing joint in a hard-pipe installation accommodates only horizontal motion, whereas a flexible fire sprinkler connection can move in any direction during a seismic event, providing overall seismic protection.

Design professionals can also design the sprinkler system so that no clearances around the sprinkler penetrations are required. This is accomplished by tying together the sprinkler system and ceiling grid, considering the mass and flexibility of all elements involved. By specifying a flexible fire sprinkler connection, you not only tie the systems together, but also provide for independent movement of the systems during a seismic event in both horizontal and vertical directions. Thus, flexible fire sprinkler connections can offer complete seismic protection, satisfying the code requirements. In addition, the sprinkler installation maintains the aesthetics of a "normal" building, without the need for requiring an oversized ring, sleeve or adapter at each sprinkler head penetration.

Invented to Meet Extreme System Integrity Requirements

The first viable flexible fire sprinkler connections were developed for semiconductor manufacturing facilities. Initially designed for exhaust-duct protection, the technology was then adapted for suspended ceilings in cleanrooms. The flexibility of the connection eliminated concerns about hard-pipe armover joint leaks or particulate generation caused by seismic activity or building shifts, as well as providing fast-track construction and the ability to easily accommodate future space changes. High-quality welded stainless steel construction and a custom-designed fit-up also contributed to the extreme system integrity demanded in cleanroom environments.