As business and personal travel rapidly return to pre-pandemic levels, hotels worldwide are being increasingly challenged to reduce energy costs while meeting or exceeding aggressive new sustainability goals.

Such was the case for the Delta Hotel in downtown Toronto. As one of the largest luxury hotels in Canada, sustainability and energy savings are an important part of operations for the entire Delta organization.

Of course, the hotels also maintain a careful focus on customer comfort and satisfaction, which directly relates to the HVAC system. With 47 floors, over 565 guest rooms, several meeting rooms and a 6,500-square-foot ballroom with floor-to-ceiling windows, maintaining comfortable temperatures within a narrow bandwidth is no small challenge.

However, the organization is accustomed to these types of challenges. As Pawel Szewczuk, director of engineering, Delta Hotel, explains “The organization set some very aggressive sustainability goals. All our properties will be reducing our CO2 emission by 30% by 2025 with a baseline of 2016. Lots of properties have already completed retrofit projects for lighting and other low-hanging fruit. Now we’ll all have to dig deeper.”

Since HVAC systems account for an average of 34% of a building’s energy, the quest for greater energy savings and sustainability enhancements led the hotel to reach out to Armstrong Fluid Technology to explore how the HVAC system components could help them achieve these goals.

The Delta Hotel in Toronto upgraded one of its existing dualArm pumps to an Armstrong Tango pump with 10hp Design Envelope motors. Even though the original pump was only 3.5 years old, Armstrong was confident that with a new design, new control algorithms and new performance management features the Tango pump would be even more efficient.

The Delta Hotel in Toronto upgraded one of its existing dualArm pumps to an Armstrong Tango pump with 10hp Design Envelope motors. Even though the original pump was only 3.5 years old, Armstrong was confident that with a new design, new control algorithms and new performance management features the Tango pump would be even more efficient.

The hotel has four mechanical equipment rooms, one booster equipment room, several heating system pumps, boiler pumps, chilled water pumps and cooling system heat exchangers. Existing dualarm pumps with a flow of 184 gpm and a head of 107 feet were a key component of the HVAC system.

One energy-saving solution Armstrong immediately identified was replacing the dualarm pumps with new parallel sensorless pumps featuring integrated intelligent controls.

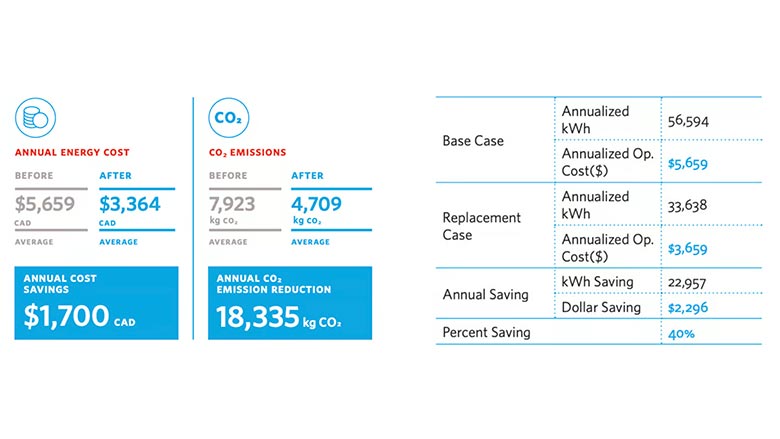

“We were confident that parallel sensorless pumps with new control algorithms and performance management features could achieve a minimum 40% energy savings, resulting in nearly $2,000 savings per pump annually,” says Paul Scarafile, commercial director, Armstrong Canada.

The new installation helped Delta Hotel achieve 40% in energy savings, resulting in nearly $2,000 in savings per pump annually.

The new installation helped Delta Hotel achieve 40% in energy savings, resulting in nearly $2,000 in savings per pump annually.

Armstrong’s optimism was based on several special features built into the new pumps. “Parallel pumping provides optimized part-load operation using a quadratic control curve, and it is selection-optimized against load profile so the pumps are always working to dynamically adjust equipment to match system demand,” Scarafile says.

Other advantages of intelligent, integrated parallel pumping include:

- Factory mapping of motor and inverter variations to achieve exceptional accuracy throughout the flow range;

- Integrated intelligent controls for space-saving installations;

- No VFD site wire/mounting, no differential pressure sensors to install, no line reactors required and lower commissioning costs;

- Energy-efficient permanent magnet motors with IE5 Rating for less energy use, reduced weight and size for easier and faster installation, and reduced noise and vibration for quitter operation; and

- Remote cloud-based performance tracking provides Performance Management capabilities such as alarms, alerts and analytics on any web-connected device.

Another major advantage of some intelligent pumps is that they measure flow so accurately that they effectively function as a flow meter. In new installations, that means expensive flow meters are no longer needed.

The new pumps have been operating for three years now and the annual energy cost savings and CO2 emissions savings have been most impressive.

“It exceeds expectations. You deliver a product that’s reliable, serviceable and has low operating costs. And now, on top of that, you throw in analytics. It’s great,” Szewczuk summarizes.