The passage of the Infrastructure Investment and Jobs Act last year will help inject billions of dollars into both potable water and wastewater upgrades over the next several years. Coupled with that, President Joe Biden has issued an executive order and Federal Sustainability Plan that will put the U.S. federal government on a path to reach net-zero emissions by 2050, which includes directives for federal buildings and facilities to achieve net-zero emissions by 2045 through energy efficiency, electrification and use of carbon-free electricity along with sustainability principles.

It’s only natural to assume that these lofty federal sustainability goals will trickle down to state and local governments in time. As buildings are some of the largest energy consumers and carbon emissions, commercial building owners and facility managers will be looking for ways to increase energy efficiencies and reduce waste. Plumbing engineers are uniquely suited to help them do both.

Smart, energy-efficient pumps

Although they may have a higher initial cost, smart pumps are some of the best options to achieve actual cost-savings for customers.

“We are definitely seeing a drive toward electronically commutated motors (ECM) in the market today,” says Ryan Coppola, product offering specialist — circulators, valves and hydronics, Armstrong Fluid Technology. “It started with larger commercial pumps going from five to 20 horsepower. We're now seeing that trend focused on small, fractional horsepower, even down to our 45-watt circular offering. The trend is definitely going even further into high connected variable speed offerings. Beyond that, we’re seeing models that can connect to a BMS signal through Modbus or BACnet protocols. They have touch screen displays where you can toggle through different startup wizards, fault codes and repair options, as well as changing the speed on-site of the product offerings.”

Coppola notes this growing trend stems from the increasing popularity of smart home products in the residential market.

“The drive to being connected comes from the smart home systems that work with Alexa and Google Home,” he says. “We’ve seen that as well on the commercial side. The building management system (BMS) sees all the information — what’s working, are any pumps down or are they all working to full capacity — everything people are interested in. You don’t just plug it in and walk away, people want to know that it’s working.”

Jeff Frank, global product manager, Franklin Electric, notes that the industry has continued to take steps toward pump system optimization through efficient product and system designs.

Frank adds that as various costs increase, end-users continue to be more conscious about the total cost-of-ownership and the energy costs that factor in.

“When the pump-motor assembly and VFD are designed and built together, they work together more effectively,” he explains. “Maximum efficiency is engineered into the entire system. This benefits the user in terms of energy cost savings, ease of installation and streamlined maintenance.”

Trends in the pump market are very different than in the past, notes BJ Hentrup, marketing manager, Zoeller.

“We’re seeing the need for products to be ‘connected’ to your devices, the need for products able to be installed easier and the need for products to look aesthetically better than before,” he says. “Most of these things are newer in this market. The way it used to be, the market just needed the product to function with no issues. Now, it needs to function with no issues and look the best — even if something is going down in a sump or sewage pit or in the ground for nobody to see. Consumers want products to be easy to work with, compatible with connected devices and having a product that looks the best.”

Mathias Bullmer, global product manager, Bell & Gossett, agrees that the top trend in the pump market is the shift toward smarts and efficiency.

“We’re seeing more integrated drives, more information feedback from pumps and more efficient motors such as permanent magnet motors,” he says. “The increased focus on sustainability is a huge driver in efficiency focus. Owners don’t just want to save money, but also create a positive change and lower their carbon footprint. In terms of smarts, this is really driven by the information world we live in today. Everyone wants info ready at their fingertips, and pump health & performance are no different.”

Barry Nauss, area sales director DBS HVAC/OEM-US, Grundfos, notes that OEM manufacturers are looking for products that have two-way communication that their equipment can then adjust based on the output results.

“Maximizing equipment efficiency and providing on-board troubleshooting is becoming the new standard,” he says. “Equipment today is much smarter than even a few years ago. Installing contractors need to be up to date with current control systems.”

Increased need for connectivity

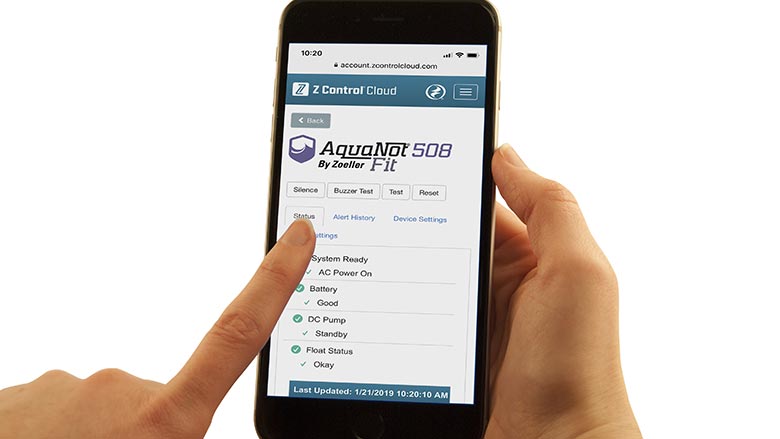

According to Hentrup, connectivity is a growing need/want in both residential and commercial applications.

“This need will not be going away any time soon,” he says. “That is why we offer the Z Control Platform, which enables some alarms and battery backups — we offer the capability of having that connectivity. Knowing you can receive messages and notifications from some of the compatible products we offer is such a peace of mind.”

However, Frank points to connectivity being preferred more for larger projects.

“Specifically within the drive unit, when access is needed for monitoring logs, assisted setup and troubleshooting,” he explains. “Users might also prefer companion apps to minimize contact with the physical unit when safety is a concern. From a product design standpoint, we continue to provide a versatile array of solutions catered to the different needs of the installation professionals: From basic plug-and-play systems to full-featured system solutions.”

Nauss notes that pump connectivity is a common request that will increase as the industry adapts to current technology.

“When a circulator pump is installed, it could be in a spot that’s not easily accessible to go in and look,” Coppola explains. “They could be inside a wall on every floor of a 50-story building to manage the flow on each floor. Before, if one went down, nobody would know until the tenant complained to the owner or maintenance. Then, they would have to go investigate and figure out the problem. Today, with connected circulators, the building owner knows exactly when the pump went down before any complaints from tenants.”

Additionally, connectivity allows for remote adjustments of parameters to better and more efficiently run the pump based on application, as well as provide feedback on things such as pump health, Bullmer notes.

Future outlook

The pump market is experiencing the same supply chain challenges as every other industry is currently undergoing.

“The biggest challenge is the supply chain for components,” Nauss notes. “Lead times and logistical concerns are an everyday subject. However, Grundfos has an advantage in its global reach and many years of experience sourcing items from around the world.

“As the pump industry shifts to ECM technology, specifying engineers and installing contractors should look at total system efficiency — with the pump being one important component of a system,” he adds. “With different types of fuels, renewable energy, and the system components, the basic heating system of the future will be significantly different than it is today.”

Frank agrees, noting that supply chain disruptions have impacted water systems manufacturing, and Franklin Electric has been working hard to stay ahead of any supply chain manufacturing challenges by making strong investments in raw materials. “This has helped us mitigate some potential shortages across various critical product lines. We’ve also been helping customers identify available alternatives that provide an application-based solution and minimize disruptions without compromising our commitment to deliver quality products.”

When asked what industry professionals should watch for in this space, Frank points to submersible pumping systems evolving to take advantage of permanent magnet motor designs that have become popular in other industries.

“Running these in specific applications can provide energy savings that quickly offset additional initial investment costs,” he says. “We’ve found that our motors with a 90% efficiency rating provide an investment payback of less than two years in most long- or continuous-run applications.”

Bullmer notes the market will see a continued push into smart solutions from both a product standpoint as well as backend support.

“We’re seeing people are interested in the latest technology and having these smarter systems in the market today,” Coppola says. “But there are definitely some who aren’t interested in such — they want the lowest price to put in place and run. However, we’re seeing now that an ECM motor will be required by building code within the next few years — right now, it’s a two-year plan, but it depends on a lot of things. Ultimately, if someone is interested in the basic product and lower cost, they will still have to go with the ECM option to meet the building code, which is why we’re starting our low-cost ECM product offering, then moving to more smart, connected full featured product in the next phase. We’re aiming to give people more options within that connected space.”