Mature plumbing practices such as backflow prevention and scald protection will always be critical to the health of the user. Newer practices need to be codified and standardized so that plumbing engineers, inspectors and owners understand how to treat new products that give added benefits to plumbing systems. With a small army of new and existing experts, ASSE International has branched outside of its traditional wheelhouse and into new areas where product performance needs to be better defined.

Commercial water treatment

Water treatment standards have received a big boost of definition in the upcoming Uniform Plumbing Code (UPC). For decades, the plumbing aspects of commercial water treatment products have gone unaddressed as exemplified in the model plumbing codes. For example, there always was a mismatch between the plumbing codes serving all types of installations versus the standards making a distinction between residential and commercial installations. There are large capacity commercial water softeners on the market, and NSF/ANSI 44 covers the cation exchange requirements well for most installations. However, the standard is intended only for residential products.

Another example is pressure loss. It is critical to understand what the flow capacities are for each component being installed in a system. There has not been a requirement in the existing body of water treatment standards that covered a method to verify manufacturer claims of pressure drops, or even that the products have a claim.

These scenarios, along with the need for backflow protection during system regeneration, ability to withstand a water hammer shock, and structure integrity testing for non-commercial modular systems, resulted in the genesis of the ASSE 1087 standard.

Now, the 2021 UPC, from the collaborative efforts of ASSE and NSF, will define the appropriate standards for use in various treatment applications, whether point-of-use (POU), point-of-entry (POE) or commercial. Aside from commercial modular products used in a treatment train, ASSE 1087 is the required standard for commercial products.

Water heaters that prevent scalding and thermal shock

The 2021 UPC and International Plumbing Code (IPC) will feature new methods to control water temperature at point-of-use (POU). There are many water heaters on the market that have been able to control their output temperatures to within the tolerances of existing mixing valves. In each of those cases, there has been a requirement to add a mixing valve downstream of those water heaters since the model codes did not allow for a water heater to control POU temperature. This is changing.

When a water heater is compliant to ASSE 1084 for POU fittings or ASSE 1085 for emergency fixtures, the UPC and IPC will no longer require additional thermostatic or temperature limiting devices to be installed downstream of the water heater. One notable exception will be for showers where mixing valves compliant with either ASSE 1069 or ASSE 1016 / ASME A112.1016 / CSA B125.16 must be installed. In all other cases, the water heaters meet the anti-scald and anti-thermal shock requirements present in the mixing valve standards.

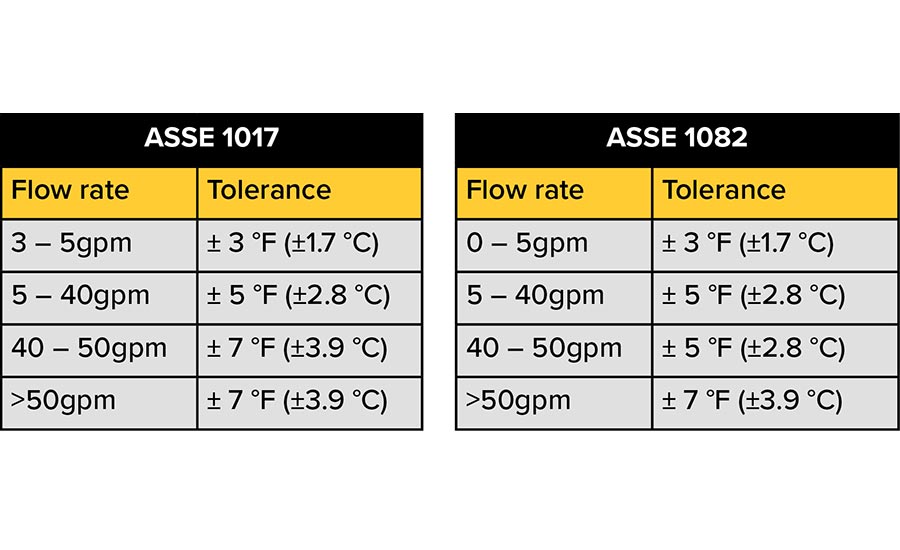

System designs that incorporate master mixing valves for distribution (ASSE 1017 devices) also have a new option with water heaters that comply with ASSE 1082. When designing for pathogen prevention using hot water as the method of control, a water heater that complies with ASSE 1082 is able to provide similar output temperature tolerances as a mixing valve that complies with ASSE 1017, as shown in Table 1. This predictability allows for designers to better balance disinfection with energy costs.

Output Temperature Tolerance Comparison between ASSE 1017 mixing valves and ASSE 1082 water heaters

Reverse osmosis efficiency

Reverse osmosis (RO) systems used in desalination plants and other large-scale facilities will place the ROs in series so that the reject water can be concentrated to its fullest reasonable level, with 80% recovery or higher. Conversely, there are some residential systems that have 5-15% efficiency in generating product water, and some that have efficiencies above 40%. These higher efficiency systems are being lumped together with lower efficiency systems and disallowed from being installed in certain jurisdictions. The industry responded and created the upcoming ASSE 1086 standard for high efficiency ROs in an effort to reopen those drought-sensitive markets.

The standard balances the claimed minimum 40% efficiency based on NSF/ANSI 58 testing versus maintaining product flow rate through the membrane (i.e., the membrane does not foul). It also promotes good plumbing practice by requiring an air gap device to connect the reject water output to the drain rather than a saddle valve that pierces the pipe. Look for this standard to be published in early 2020.

Innovative water treatment

There are some technologies that have not widely been seen or utilized due to the lack of transparent criteria used for third-party certification. These new entrants need to have the ability to show what they can achieve. One way to allow for this is to create a Listing Evaluation Criteria (LEC) document. LECs allow for a manufacturer to test the market while being certified to the LEC, thereby educating clients and AHJs. Two new LECs were released this year: LEC 2004 for water treatment devices that use a condenser to generate water from humidity, like those developed by Skywell and WaterGen; and LEC 2006 for whole-house and larger POE RO devices being developed by HANS Premium Water.

We are looking forward to what is next in plumbing and helping those products find a confident place with AHJs and engineers.