Upfront costs and energy consumption are primary drivers when selecting a commercial HVAC system in new and retrofit projects. A study commissioned by Xylem underscores the importance of evaluating total life cycle cost in the selection process to adequately identify pros and cons of various system types.

To anecdotally compare and contrast HVAC systems according to their 30-year life cycle cost analysis (LCCA), the Xylem study analyzed seven elementary and middle schools located in South Carolina Climate Zone 3A, a humid, warm climate. The cost analysis includes upfront installed cost, replacement cost allocations and ongoing energy and maintenance cost of the following system types:

- Variable refrigerant flow heat pumps (VRF);

- Water source heat pumps (WSHP);

- Ground source heat pumps (GSHP);

- Direct expansion rooftop units (DX RTU);

- Water cooled chillers (WCC); and

- Air-Cooled Chillers (ACC).

With HVAC systems dictating as much as 50% of the overall energy use of K-12 buildings, according to ENERGYSTAR, the results of the study serve to inform decisions and promote maximized energy savings across the commercial construction industry.

Methodology

Over a three-year period, utility cost (electric and natural gas) and average maintenance cost were collected. For a more accurate comparison, construction costs were estimated according to the year each building was built. Utility rates and square footages of these facilities were also normalized to remove any other outside factors. The average electric rate ($k/kWh) and natural gas rate ($/therm) from the sample buildings were multiplied by each building’s electric and natural gas consumption to calculate a normalized energy cost ($/square feet) for each building. Each building’s square footage was also considered when calculating maintenance and installation cost.

Analysis finds hydronic outperforms VRF

From a life cycle cost perspective, the primary drivers of a purely economic decision of all HVAC system types are installation and energy cost.

However, these costs are often interrelated with a maintenance department’s unfamiliarity and uncertainty with any given system, eventually showing in the form of increased utility cost from overrides and other changes to the system design.

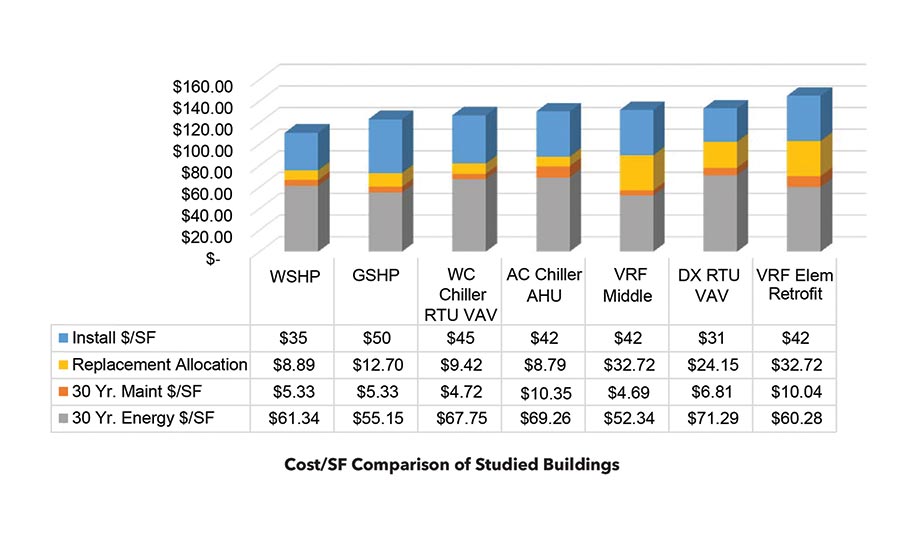

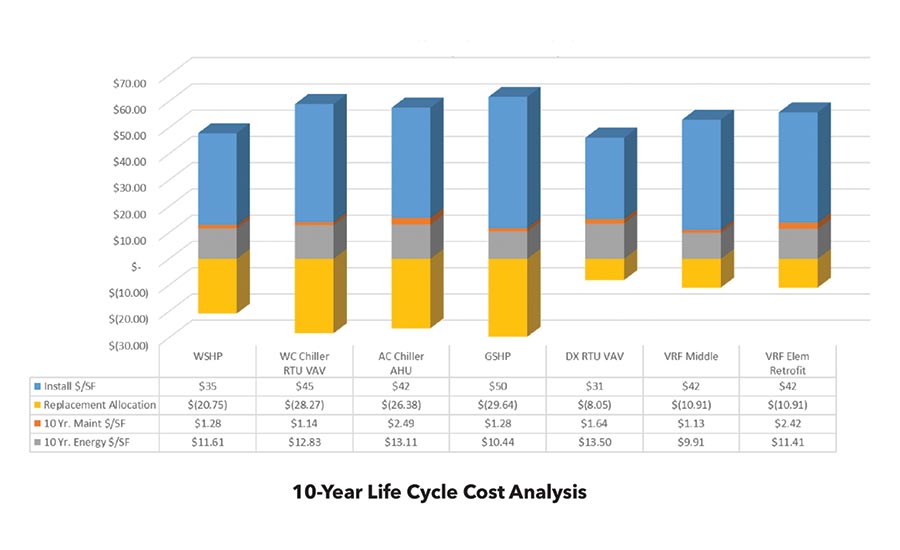

The study’s findings resulted in the following ranking in life cycle cost analysis from lowest to highest. As exhibited in Figure 1, replacement allocations had an impact on the life cycle cost analysis (see yellow bars) and drastically reduced the cost effectiveness of equipment with 15-year life expectancies.

As design engineers, building owners and mechanical contractors strive for more sustainable and energy-efficient practices, these findings shed light on the differences among systems, particularly hydronic and VRF systems.

Specifically, the study revealed that the schools with water source heat pumps, ground source heat pumps and water-cooled chiller systems displayed energy use levels that were 30%, 41% and 25% better than the national median for elementary and middle schools, respectively. The replacement cost allocation also acknowledged that the tested hydronic systems operate effectively for approximately 25 years, as opposed to the 15-year replacement estimation for VRF systems.

The tested VRF systems required replacement a decade earlier because of their tendency to work harder during heating cycles, bringing proof of long-term cost savings to the forefront of the conversation surrounding sustainability and hydronic HVAC system efficiency.

Along with shorter life expectancy, costs of VRF systems are generally reported to be between 5% and 20% higher than hydronic systems due to their complicated refrigerant management system and controls. Additionally, VRF systems are proprietary and require specialized technicians for installation and maintenance, compared to hydronic water systems designed with universal components that can be installed and serviced by any HVAC service technician.

This will also add to life cycle costs as building owners will be reliant on the VRF manufacturer for the life of the building. In hydronic systems, component manufacturers can be changed and new technologies installed.

The initial cost of a hydronic system is generally lower, and systems offer a much wider range of flexibility for components, operation and maintenance, both in terms of parts and service. Advanced systems include application of technologies such as integrated and single-pipe systems that dramatically reduce piping and costs, and pumps equipped with variable speed drives that increase energy efficiency.

Components in a hydronic system are factory made and tested, reducing rate of failure after installation. Since VRF piping requires brazing and soldering on-site, the quality of the installation depends on the level of expertise of the installer. Installers also must be qualified to work with refrigerants under extremely high pressure and be knowledgeable about leak detection and ventilation requirements per ASHRAE Standard 15.

With HVAC systems dictating a substantial amount of the overall energy use of commercial buildings, the results shed light on the importance of evaluating varying system-to-system costs before installation. As energy-efficient practices continue to drive the construction industry toward more sustainable solutions, this study proves long-term cost savings that can’t be overlooked when making the choice between hydronic and VRF systems.

Consider pump type

Designing an HVAC system for a commercial application should also include an evaluation of the type of pump used. Pumps play a major role in all HVAC systems, and due to the nature of their application, design and operation, pumps provide an excellent opportunity to reduce costs and increase reliability in a HVAC system.

The way for engineers and facility operators to make the best choice of a pumping system that delivers on the building owner’s objectives of keeping costs to a minimum is to consider the HVAC system as a whole — and how each system component contributes. From that foundation, it is useful to examine the real benefits and a cost analysis of different pump styles.

Building designers, owners and contractors are cautioned against specifying and installing pumps simply based on purchase costs. To choose the best pumps for commercial building HVAC systems, there are several key factors to consider that affect performance, reliability and long-term ownership cost.

By design, base-mounted pumps are built to last longer, as supported by the ASHRAE Equipment Life Expectancy Chart, as well as the recently implemented Department of Energy pump efficiency requirements (Figure 2). Pipe-mounted pumps like a vertical inline pump may be less expensive, and in some cases, more practical for smaller applications, but overall, base-mounted pumps are the superior choice for midsize and large commercial installations. For these larger applications, base-mounted pumps present a lower installation cost, greater energy savings, increased reliability, easier maintenance and smaller installed footprint.

With a growing emphasis on reducing energy consumption driven by government regulation and businesses seeking operational and financial efficiencies, evaluating total life cycle cost of HVAC systems and the type of pump during the selection process is vital to modern HVAC system design.