According to the 2016 Behavioral Risk Factor Surveillance Survey, nearly 26% of U.S. adults — an estimated 61.4 million people — reported having a disability, with mobility-related disability being the most frequently reported type.

As more baby boomers become seniors, the proportion of Americans with disabilities — in particular, mobility challenges — is expected to increase. As such, it’s crucial to approach the design of hospitality and healthcare spaces with accessibility in mind.

The Americans with Disabilities Act of 1990 established a series of accessible design requirements for the construction of public facilities.

Hotels and resorts

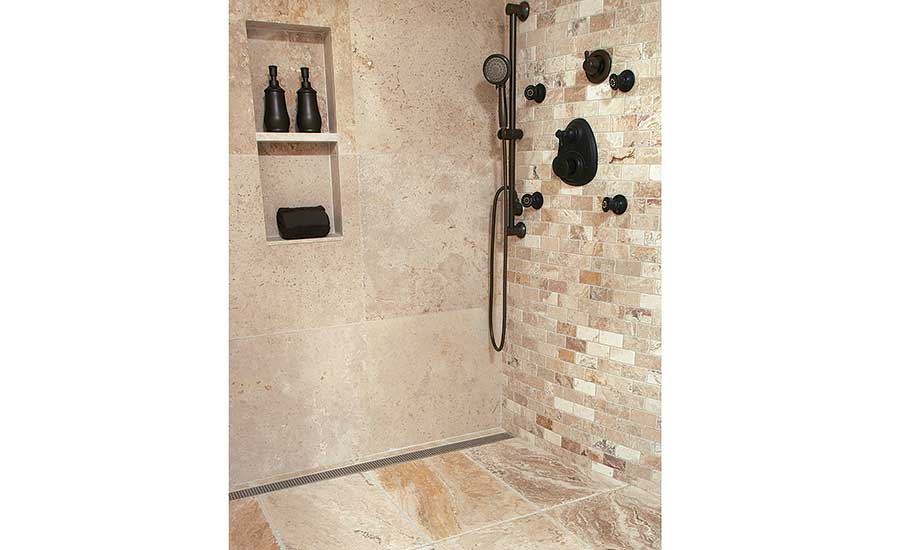

Hotels and resorts have come to recognize the importance of creating bathrooms for guests that are not only safe and accessible, but also maintain an elevated level of design. In fact, when it comes to accessible bathrooms in the hospitality setting, the lines are increasingly blurring between function and aesthetics. Curbless, European-style showers, in particular, are becoming more popular, eliminating the need for guests to step over a tub or shower threshold.

The low profile of these showers enables guests with mobility challenges to easily navigate the shower area, reducing the risk of falls. In addition, the clean, contemporary aesthetic complements a wide range of design styles, and can create a spa-like environment, which is becoming more prevalent as the wellness trend continues to gain momentum.

Healthcare facilities

Providing safe access to bathing and showering for elderly or disabled patients during their stay at a hospital, nursing home or rehab center is a fundamental aspect of care. Bathrooms in these settings must incorporate universal design concepts to ensure the comfort and safety of patients and residents. As would be expected, bathroom designs in healthcare settings are more focused on functionality than on appearance. And, just as in the hospitality setting, curbless showers are ideal for healthcare facilities.

A universal shower design eliminates the barrier typically found in the shower area, providing a safer entry and exit. Inside the shower, the single-pitch shower floor maximizes safety considerations by providing a stable surface for patients and their caregivers to perform necessary daily routines. This type of shower floor is particularly beneficial for patients who rely upon wheelchairs or walkers.

When it comes to aesthetics, linear drains offer a clean-lined appearance that is equal parts form and function.

A practical (and elegant) drain solution

With their minimalist design, linear drains are well-suited for curbless (zero threshold) showers. Compliant with the ADA, these streamlined shower drains can be installed independent of any waterproofing method, simplifying the installation process and ensuring universal compatibility. In addition, in contrast to traditional center drains, linear drains can be located almost anywhere within the bathroom space, providing design flexibility.

Linear drains also simplify navigation within the shower space. Their sleek profile enables those in wheelchairs to easily enter and exit the shower area, eliminating the need to negotiate ledges or uneven surfaces. Meanwhile, the rest of the bathroom floor remains dry, minimizing the chance for slipping.

Moreover, unlike with center shower drains, linear drains remove the barrier between the shower and bathroom floor, making it easier to clean bathroom surfaces, and reducing the chance for mold and other germs to gain a foothold. In addition, the drain grates are removable, which simplifies maintenance and cleaning.

When it comes to aesthetics, linear drains offer a clean-lined appearance that is equal parts form and function. They make it possible for designers to specify larger format tiles, which have been gaining traction in the hospitality setting. Tile insert drains are another increasingly popular option where design is a consideration. These versatile drains use the same tile used on the shower floor, which creates the illusion that the drain has disappeared into the floor for a seamless look.

When selecting a linear drain, it's important the drain is UPC certified, which ensures that the materials have been tested in a lab to meet American Society for Testing and Materials standards.

Specifying linear drains

Understanding how to properly specify a linear drain is crucial in ensuring a proper fit. A designer or engineer may specify a 38-inch drain, but once the wallboard, tile and mortar are installed, that 38-inch gap closes down to 36 inches. It’s important to keep in mind the tile and other materials being used in the space along with their thickness, and to understand the difference between nominal size and actual size. Most specifiers have CAD programs that should take that difference into account, but it is often overlooked.

While linear drains are offered in standard sizes, they also come in custom sizes and configurations. Many times, restrictions and boundaries are encountered in the field, necessitating a custom approach. For example, a location may require a 34.5-inch drain with the outlet 3 inches off center. In cases such as this, a designer or engineer can draw the drain and then it can be created to spec.

A second option is to go with a modular drain solution. Modular drains feature a variable outlet position for flexible installation in the shower area, and can be sized onsite (site adjustable) and then cut to the desired length. Two or more kits can be joined for longer drain runs. Whereas a special order linear drain option typically requires a minimum eight-week lead time, a modular drain kit serves as an off-the-shelf, customizable option when timeframes are tight, and it is not possible to wait for a custom order to be delivered.

With standard linear drains, the outlet is centered on the drain. In contrast, modular drains allow for flexible placement of the drain outlet. Let’s say, for example, the spec is for a 33-inch drain with the drain outlet 6 inches off center. Starting with a 48-inch drain, the field engineer can cut the channel to size, drill a hole anywhere along the length of that channel, place the outlet where needed and then glue the components together with a stainless steel adhesive. Both custom and modular linear drain solutions provide significant design flexibility, which is especially advantageous in hospitality and healthcare settings.

Other considerations

When selecting a linear drain, it’s important that the drain is UPC-certified, which ensures that the materials have been tested in a lab to meet ASTM (American Society for Testing and Materials) standards. The products should also be manufactured in accordance with ASME standards and approved by IAPMO for residential and commercial use in North America.