Line pressure in a water heating system is a lot like your body’s blood pressure: an initial indicator of overall health.

If the line pressure is too high for too long, bad things happen throughout the system: premature failures of the water heater, solenoid valves, toilet valves and more.

Twenty years ago, water pressure in many communities seldom exceeded 50-60 psi. Now, it’s common to see water pressure of 120 psi or even higher. That’s because fast-growing communities essentially have two options to meet the additional water demand: they can either dig up miles of existing water lines and replace them with larger ones (a very expensive choice) or they can install larger pumps and increase line pressure. It’s no surprise most municipalities have chosen the latter option.

There are two types of valves designed to prevent line-pressure problems in water heating systems. The pressure relief valve is just a safety device designed to prevent tank pressure from exceeding 150 psi. A pressure-reducing valve is what actually controls line pressure and insures proper operation.

For residential water heaters, the maximum allowable water line pressure is 80 psi or below. However, most commercial water heating systems typically operate at much higher pressures. Local codes dictating maximum line pressures in these applications can vary greatly. But when a contractor recommends an expansion tank to commercial customers that don’t have one, they often feel like they’re being upsold. The reality is that adding a thermal expansion tank, in any application, is a relatively inexpensive safeguard that will pay for itself by greatly extending the life and performance of the water heater, as well as any other device connected to the system. And, more and more local municipalities are making it a requirement.

Two types of pressure

The line pressure coming from the street is usually called static pressure, even though it’s never truly static for long. Then there’s the dynamic pressure that comes from thermal expansion as the water is heated. Since most commercial water heating systems are “closed” plumbing systems, service pressures can raise dramatically as the water heater cycles. In fact, it’s not uncommon to see a pressure relief valve opening on a water heater at 150 psi due to thermal expansion alone.

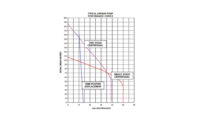

To effectively monitor line pressure, contractors need to use two types of gauges. The first is a standard water pressure gauge that plugs into the plumbing system at a hose bib or on the water heater drain valve. The more important gauge is the one that provides a picture of line pressure over time. This gauge has a red “lazy hand” or “recording hand,” in addition to a black pressure hand.

One hand pushes the other so that you can see current line pressure and the highest pressure reached in a certain time period.

If a contractor puts this dual gauge on and comes back the next day, he can see exactly how high the pressure got. This is important because you always want to size the system based on the worst-case scenario – and this identifies any thermal expansion problems in the system.

If the installed system has a thermal expansion tank that is working properly, there should be very little line-pressure fluctuation in a 24-hour period. But if the expansion tank’s bladder has failed, there will be a lot of fluctuation. It’s a quick and easy way to see if the system is operating correctly.

Regular checkups

Most people have their blood pressure checked several times a year. But many commercial businesses don’t feel the need for regularly scheduled water heating checkups – even when hot water is the lifeblood of their business (e.g., restaurants and hotels).

In the HVAC world, spring/fall tune-ups are commonplace. A twice-yearly water heating checkup is a way to monitor the heartbeat of the system and make sure everything’s operating properly. Contractors who do regular water heating checkups are actually flattening their sales matrix by staying in regular contact with their customers. They’re able to solve problems and identify less costly solutions before the system experiences a catastrophic failure.

Business owners are accustomed to periodic HVAC checks because they interact almost daily with those systems. In contrast, the water heating system is often “out of sight, out of mind,” but regular preventive maintenance can save business owners thousands of dollars in the long run.

Every business is under pressure to boost profits – and routinely checking water line pressure is a great way to do that.