A few months ago, PM Engineer ran an extensive feature article on FOG (fats, oils and grease) and the importance of using grease interceptors to keep kitchen grease out of the municipal sanitary system.

Because the article was very well received, PME then decided to survey its readers about their design practices with grease interceptors. This article provides and analyzes the results of that survey. The survey addressed both types of grease interceptors, hydro-mechanical and gravity, and provided for some very interesting results.

We sent questionnaires to 1,600 of our readers and 18% responded. In the area of marketing surveys, 18% is outstanding. Usually, a response of 3% is considered to be very successful. So, again, thank you for your responses and involvement in the industry.

What We Asked

This survey encompassed 19 questions [14 sliding scale and five “yes or no”] broken up into five sections. Section one focused on general standards and location; section two on type, size and related systems; section three on food-service establishments; section four on maintenance and section five on how food-service establishments eliminating trans fats has impacted designers.The first question we asked was: When designing a drainage system, do you include a grease interceptor to capture fats, oils and grease? More than 97% of those responding gave an affirmative answer. The answer could have easily been 100%, but we suspected that some engineers do not get involved with drainage systems that have grease laden waste.

Just 2% of readers said they let the plumber decide which standard to use. And the same amount selected “other,” noting their preferences such as using EPA guides, manufacturer recommendations and flow requirements.

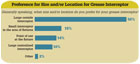

Most respondents (56%) selected large outside interceptor. Once again, there was a large drop off to the next preferred answer: small interceptor in the area of fixtures (18%). The next option, point of use at the fixture, drew a 14% response, followed by large centralized interceptors (10%). Just 2% selected “other” and said they simply size the interceptor per job application (small or large sink). This was somewhat of a shock since we expected the highest response to be smaller interceptors in the area of the fixture.

The next question regarded how often participants had to submit any special information to a jurisdiction to gain approval of a grease interceptor. Based on reader feedback, it appears this approval step is not required most of the time (53% no to 47% yes). The type of information that is submitted, according to our survey results, ranges from calculations to grease trap sizing formula on drives to venting requirements.

Sizes and Systems

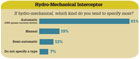

Section two focused on issues related to interceptor type, sizes and related systems. Question five asked: What type of interceptor do you prefer? The options were hydro-mechanical (HM) or gravity, and replies weighed heavily in favor of gravity (89%).Question five also had more subquestions - two on HM interceptors and two on gravity interceptors. The first HM question asked designers about the type they specified most. A whopping 61% selected automatic (grease removal device). In descending order came manual (19%), semi-automatic (13%) and do not specify a type (7%).

Next, we asked which material type and flow rate they prefer for HM interceptors. Nearly one quarter (23%) said stainless steel - small to medium. Exactly 17% selected coated metal - small to medium (4 to 25 gpm), metal - medium to large (30 to 100 gpm) and thermoplastic - medium to large. A smaller percentage selected stainless-steel medium to large (13%) or thermoplastic - small to medium (3%). Ten percent had no preference.

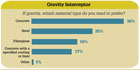

As for gravity units, first we wanted to know which material type readers preferred. Concrete is most popular (38%), followed by steel (25%), fiberglass (19%) and concrete with a specified coating or liner (17%). Also mentioned (1%) was cast iron.

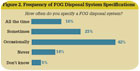

Our survey then asked about systems used in conjunction with interceptors. In question six (Figure 2), we wanted to know how often you specify a FOG disposal system. Two-thirds of readers said either occasionally (42%) or sometimes (23%). One-sixth, or 16%, said all the time. About the same amount (14%) said never, and 5% didn’t know.

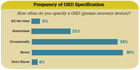

To close section two, we wanted to know how commonplace it was for you to specify a grease recovery device (GRD). More than two-thirds said never (36%) or occasionally (34%), while 21% said sometimes. Those who specify GRDs all the time or didn’t know numbered just 5% and 4%, respectively.

Food-Service Establishments

Next came a question about food courts; specifically, how often do you allow multiple establishments to connect to a single interceptor? By a wide margin, respondents said “never” (39%). Interestingly, the next highest answer was don’t know with 24%. Rounding out the responses were occasionally (16%), sometimes (15%) and all the time (4%).

Maintenance

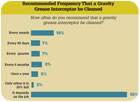

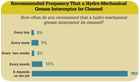

Maintenance is very important to the effectiveness of an interceptor so we included three basic questions. First was whether your specifications require or recommend maintenance after installation. The majority said yes (57%). While this is a high number, manufacturers of grease interceptors would prefer to see an answer of 100%.Second, we wanted specifics on frequency of maintenance for hydro-mechanical interceptors. More than three-fourths of you said it depended on the job (78%). Others said every month (11%), every week (7%), every two weeks (2%) or every day (2%).

It was good to see such high numbers for maintenance being required based on the job or installation. Most manufacturers recommend that every grease interceptor be evaluated for the particular installation.

Final Question

There has been a lot of discussion in the mainstream media recently about the need for food-service establishments to cook healthier by eliminating the use of trans fats. PME was interested to know how much this trend has impacted its readers, so it addressed this topic in the last question of the survey.We asked: If a facility has eliminated the use of trans fats, has this impacted your design of a grease interceptor? In no uncertain terms, readers told us NO! In fact, only 3% said they had been impacted.

Some manufacturers have expressed a concern that the reduction in trans fats may require an evaluation of the grease interceptor design. This is based on the fact that lighter oils are being used that may not be intercepted as well. It is clear from the survey that the engineering community does not agree with this conjecture.