Last month, we began a discussion of how tubing depth affects the thermal performance of heated slabs. Based on computer simulations, we found the effect is significant. This month we’ll continue the discussion with a look at bare slabs. We’ll also look at some details for protecting tubing where it passes beneath sawn control joints.

Unlike relocating a sensor or unthreading a pipe fitting, there’s no way to change tubing depth once the concrete is placed. The thermal performance of the slab with its embedded tubing is now fixed for the life of the building. The irreversibility of the situation should make us question if we’re installing the tubing in the best manner possible.

If the depth of the tubing doesn’t have much of an effect on performance, why worry about it? On the other hand, if depth does have a substantial effect on performance, why be ignorant of it? Why sacrifice performance to a detail that adds very little, if any, to the cost of the system?

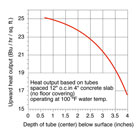

Figure 1

Slab Simulations

Like most engineers, my comfort zone with a design issue is usually bordered by numbers. To get a handle on the tube depth issue, I turned to a specialized technique called finite element analysis (or FEA for short). FEA software allows one to build a model of the situation you want to test, run it, and then see what the temperature would be at any point you’re interested in. The calculations this software does in a couple of seconds would take weeks to complete by hand.One of the models I constructed and discussed in part one consisted of a 4" concrete slab sitting on 1-inch (R-5) polystyrene insulation and covered by 3/8" oak flooring. Several versions of the model were used to simulate tubing at different depths in the slab. Each time the model is run, it determines the temperature at hundreds of points within a small region of the slab, including points spaced 1/2 inch apart along the floor surface.

Using the temperature data from several runs of the FEA software, I estimated the heat output from the system for water temperatures of 100

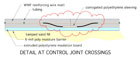

Figure 2

Lift Here"

Of course, there are factors other than thermal performance that have a bearing on tubing depth. One of them is protecting the tubing near sawn control joints. The depth of such saw cuts is typically 20% of the slab thickness. I prefer to keep the tubing near the bottom of the slab at such locations to give the blade a wide berth as it passes over. A typical detail is shown in Figure 2.Another consideration is penetrations by fasteners used to secure equipment to the slab. In most cases, it doesn’t make sense to leave all the tubing at the bottom of the slab just to accommodate what might be a future bench or lift post. Find out where such equipment will be placed and keep the tubing a couple of feet away from where the fasteners are likely to go. Block out and note these areas on your tubing layout drawing. Be sure to leave a copy of the plan with the owner, since nobody will remember where the tubing is a few years after it’s installed.

Summary

Although FEA simulation is a theoretical approach, the results obtained agreed fairly well with other published models for upward heat output.

The predicted increase in water temperature required for tubing at the bottom (rather than the center) of the slab is both believable and significant.

A nominal 10% increase in downward heat loss caused by higher water temperatures in bottomed-out tubing also was predicted.

Also keep in mind that these results are based on steady-state simulation. They don’t predict the consequences of the longer response times associated with deeper tubing. Mix strong internal heat gains into such a situation and you’ve got the potential for significant overheating.

Considering the degraded performance of tubing at the bottom of slabs, I feel it’s imperative to ensure that tubing is placed at the proper depth. For starters, be sure this is clearly shown on your plans and written into your specifications. Follow up by discussing the importance of the tube depth detail with those responsible for concrete placement.