Are you surprised that last year the International Code Council (ICC) withdrew its preliminary deal with the International Association of Plumbing and Mechanical Officials (IAPMO)? The deal was to create a single plumbing code and a single mechanical code. A single plumbing code is obviously lacking in our country. Similarly, we do not have a single mechanical code and a single building code. We do have several nationally accepted standards that become codes when adopted locally.

Namely, we have standards for pipes, plumbing fixtures, electrical installations, fire sprinklers, steel, concrete, appliances and many portions of the built environment. A single plumbing standard adopted universally would be helpful economically. Further, obstacles to achieving that goal will be viewed as petty when history looks back at our day. Nonetheless, the current development process is locked over fundamental issues.

Previous Guest Commentaries

In the Sept. 2006 issue ofPM Engineer, Guy Tomberlin wrote a guest commentary (pp. 8-24) describing the outcome from a meeting in Falls Church, VA, between ICC board members, ICC staff and five organization representatives from Virginia. The five identified two major contentions with the joint venture to create one plumbing code. Tomberlin, as one of the five, expressed his sympathy in the commentary.Then last November in PME, Jay Mundy wrote eloquently (pp. 18-22) in response to Tomberlin’s description of the Virginia meeting. Mundy, an IAPMO proponent, is clearly in favor of resuming the joint venture where it left off. For me, for the moment, the squabble is generally academic because Wisconsin, where I practice plumbing engineering, has not adopted either model code. Nonetheless, many of our clients are throughout the United States and so we adapt our plumbing designs to both model codes, to state-amended model codes and to local codes as required.

Regarding the tone of the two commentaries, Tomberlin appeared to be frustrated, while Mundy’s tone was carefully measured. The varied tones appear to reflect the apparent weakness of the ICC and the current advantage of IAPMO. Further, the events characterize the ICC leadership as not having been aware of their constituents’ concerns until only recently.

Tomberlin opened his article with two major contentions in formulating a single plumbing code: an equal compilation of the provisions of each code, and an uncompromised integrity of the code development process. Expanding on only the first contention, this commentary attempts to present the merits of a few portions of both codes.

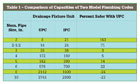

Table 1 - Comparison of Capacities of Two Model Plumbing Codes

Comparing Capacity and Safety

A sanitary building drain system, which is the lowest and nearly horizontal portion of a drain system, is an essential part of a plumbing design. As a preface, let me note that neither code reflects the benefits of smoother surfaces of today’s acceptable materials such as copper and polyvinyl chloride in sanitary and storm systems. Also, the tables used here are generally from the days when cast iron was exclusively used.Table 1shows the code-allowed maximum drainage fixture units of several pipe sizes and the amount that the UPC is safer than the IPC. The comparison is for piping at the same slope: generally 1/8 inch per foot. The assigned fixture units for sinks, lavatories, urinals and most water closets are comparable in each code.

The disparities of assigned units are with bidets, bathtubs, domestic clothes washers and domestic sinks having a dishwasher or a food waste grinder. Disparities also occur with equivalent plumbing fixtures. Nevertheless, Table 1 is a valid comparison for non-residential construction with a modest use of equivalent plumbing fixtures. The UPC appears dramatically safer than the IPC in the small pipe sizes, appears comparable in 3-inch and 4-inch pipes, but appears less safe in 8-inch and larger pipe. Further note that the IPC uses a different capacity table for horizontal branches, which shows the 2-inch and 2-1/2-inch pipe as being safer than the UPC.

Safety can be viewed in degrees, such as the ratio of the general free surface height to the pipe diameter. For example, a ratio at 0.50 represents a free surface height of half the pipe diameter. For plumbing systems designed for 0.50, the upper half of the pipe is not considered in a typical peak demand flow rate. This space is reserved for wave oscillations, other transients, material variations and other difficult-to-determine variations of a system. When a code selects 0.50 as the minimum safe ratio, then additional safety can be quantitatively recognized as the free surface height being less than half the pipe diameter.

Safety also should include a discussion of the particular hazards that are to be avoided. In a sanitary building drain system, such hazards include no flow or even reverse flow from fixtures, an inability to receive additional flows and water velocities that are too high or too low. The former disturbs trap seals and the latter prevents the adequate transport of solids. However, when a storm building drain system is considered, a ratio of 1.0 is considered because the health issues of backed-up storm water are less hazardous than backed-up sanitary drainage.

From Table 1, we conclude that neither code for sanitary building drain systems is superior regarding a consistent minimum safe ratio. More specifically, the degree of safety varies with the pipe diameter and whether the building is largely residential.

Other sanitary drain system parts, such as stacks, show discrepancies between the two codes. Namely, IPC stacks are safer except for some diameters in some tall buildings. Hence, neither code is superior regarding safe capacities.

Need for A Fresh Start

Since neither code is superior, a fresh start is warranted. A reasonable attempt to develop a code for a sanitary drain system can be by any of the following methods.

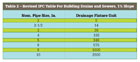

Table 2 - Revised IPC Table For Building Drains and Sewers, 1% Slope

That is, we can select the ratio of the cross-sectional area of the wetted perimeter of a conductor to the cross-sectional area of the entire inside diameter to be 1/3. This is in contrast to 1/4 being used for sanitary stacks where there is a greater hazard. Engineers commonly accept ratios of 1/4, 7/24 and 1/3. The values for the UPC are between the last two ratios, and the IPC is greater than 1/3. Hence, 1/3 is a reasonable ratio.

Similar quantified reviews of safety can be made with sanitary vent systems, water supply systems, pipe material, hot water systems, temperature maintenance systems and plumbing fixture types and quantities.

In conclusion, recent code development events have halted constructive deliberations in creating a single plumbing code in the United States. The trend is toward a common code that provides a predictable economic environment for building construction. When entrenched interests are set aside, an honest look at defined safety and recognized hazards can lead to a reasonable effort at developing a uniform and universally acceptable standard. A review of the flows within the lowest parts of a plumbing drain system can lead the way to safe tables that are derived from the existing IPC and UPC tables. Similar reviews of other parts of the two model plumbing codes can create the new code without compromising safety and without adding unreasonable construction costs.