Most currently available modulating/condensing boilers operate in one of two mutually exclusive modes: space heating or domestic water heating.

When “called” to supply a space-heating load, the boiler operates based on outdoor reset control. When called to provide domestic water heating, the boiler ignores outdoor temperature and operates to maintain a setpoint temperature. This latter temperature is typically high (160

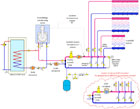

Figure 1

Smart & Dumb Solutions

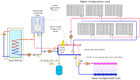

Fortunately, there are at least two ways of creating multiple simultaneous supply temperatures to the space-heating loads when necessary. The first method uses a mixing device to create a second supply temperature that’s lower than the boiler outlet temperature. The mixing device may be either a “smart mixing device” (such as a motorized three-way valve) or a “dumb mixing device” (such as the three-way mixing valve without a motorized actuator).Figure 2shows an example of the smart mixing device solution.The use of a smart mixing device allows the supply water temperature to the lower temperature load to be controlled independently of the higher temperature load. It also allows for fast recovery from setbacks and provides temperature compensation due to sub-zoning of individual circuits or manifold stations.

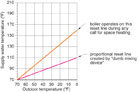

The only difference with the “dumb mixing device” solution is that no controller/actuator is used on the mixing valve. This is obviously a less costly solution, which allows the lower water temperature to be fully reset along a reset line having a shallower slope than the boiler reset line. This technique takes advantage of the fact that when the “hot” water supplied to a fixed mixing device is reset, the mixed outlet temperature of that device will also be reset along a line with a lower slope, as shown inFigure 3. This effect is called proportional reset. The greater the entering flow of cool water to hot water, the lower the slope of the reset line.

Proportional reset does have limitations. It’s not suited for situations where the distribution system is zoned downstream of the mixing valve. It’s also not recommended when the distribution system downstream of the fixed mixing valve will be operated with setback thermostats. These situations can produce sudden changes in the temperature and/or flow rate of the return stream entering the mixing valve.

Since the valve has a fixed setting, it cannot react to these variations and will not be able to maintain stable supply water temperatures when they occur. Still, in situations where the load flow rates remain steady, it definitely reduces cost relative to the smart mixing device solution and yields good performance.

The downside of using any mixing system with a modulating/condensing boiler is the need to always operate the boiler at a temperature high enough to supply the higher temperature load-regardless of the duration of that load. This reduces the potential for condensation in the boiler and thus lowers its efficiency. This is especially true when the higher temperature load operates at a substantially higher temperature than the low temperature load.

Figure 2

Two Tanks in One

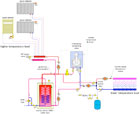

Another technique for supplying both high and low temperature loads is shown inFigure 4.Here, the boiler supplies a combination buffer/DHW tank. This type of tank is called a “reverse indirect.” The pressure vessel contains system water, while the internal copper coils contain potable water.

The operating concept of this system is simple. Whenever the tank thermostat calls for heat, the boiler goes into high temperature mode and recharges the tank to the desired setpoint. The higher temperature space-heating loads then draw from this tank (or the header leading to the tank) as needed.

The thermal mass of the tank is helpful in buffering small loads such as a towel warmer radiator or small fan-coil. This helps reduce boiler cycling, especially under low load conditions. This system also provides instantaneous domestic hot water whenever cold water is drawn through the internal heat exchanger.

The boiler receives a call for DHW heating whenever the tank temperature drops. However, the buffering effect of the tank may allow a small high temperature load to operate for some time before such a call takes place. This can occur even as the boiler is sending heat to the low temperature load. In contrast, without this tank there can never be simultaneous operation of the low temperature and high temperature loads.

This approach has the advantage of only driving the boiler to higher temperature conditions as needed by the higher temperature loads. The previous approach using mixing requires the boiler to operate on the steeper reset line required by the higher temperature load at all times, even when the only load calling for heat is the lower temperature load. This sacrifices the potential efficiency gains associated with accumulating operating hours at the lowest possible temperature.

The buffer tank temperature also can be controlled by outdoor reset control, but with a minimum temperature setting high enough to ensure that the DHW load was always being met.

Figure 3

The tank also should include a float-type air vent at the top to remove any accumulated air.

Figure 4