Over the years, I’m sure that each of you in our industry has had the opportunity to address a question or two from a friend or family member regarding just what is happening behind the finished walls within our public restrooms. Questions such as: How does a carrier or fixture work? Where does the piping go? How are these supported? These are just a few of the questions I’ve been confronted with.

Industry engineers have developed an unusually complete line of fixture supports for mounting all types of fixtures, regardless of application requirements. Many throughout the industry feel the most cost-effective and efficient type would be the “off-the-floor” fixtures. Supports have been designed for water closets, urinals, lavatories, sinks, drinking fountains, coolers, hospital service and scrub-up sinks, as well as many special-purpose hospitals, and institutional and industrial plumbing fixtures.

The commercial restroom isn’t always the most aesthetic part of the facility. It can be a constant source of problems and extra expense to maintain and keep clean. Off-the-floor installations look more expensive, but they are actually more economical in several ways. By using off-the-floor fixtures, you gain aesthetic, sanitary, structural and installed cost advantages.

Side view of an off-the-floor fixture support (carrier).

Off-the-Floor Defined

By definition, “off-the-floor plumbing fixtures” would be those that are wall mounted and have no external contact with the finished floor. Fixtures so mounted are supported on concealed cast iron or steel supports (carriers). These supports are completely concealed in the wall and support the load of the fixture by means of a suitable face plate and base support, which is firmly anchored to the floor. Thus, the load of the fixture is effectively taken off the wall and transmitted to the floor.Just what makes up a water closet support system? Water closet support systems consist of a waste fitting and the water closet support components. By incorporating a waste fitting, which functions in conjunction with the closet support section of components, an entire system of “Combined Fixture Supports and Waste Fittings” has been developed.

Thus, when mounting off-the-floor water closets, a complete unit is available that supports the fixture and includes a fitting that ties into the drainage piping system. Fittings are available in vertical and horizontal patterns. Used in combinations, these fittings can satisfy waste and vent requirements of most systems.

Over the years, industry engineers have worked closely with plumbing designers, contractors and code officials to develop a system that meets their rigid demands and requirements. Particular attention was given in design so that:

- The engineer can select supports with fittings to meet all problems created by architectural, structural, code or aesthetic requirements.

- The plumbing contractor can easily and economically install a rigid and code-approved support with fitting, which will function for the lifetime of the building.

- The code official is assured that fittings used with supports are designed to meet code requirements relative to the proper sizing for drainage piping and venting.

Figure 1. Installing floor-mounted fixtures.

Many Advantages

There are many advantages of off-the-floor water closets over floor-mounted. These include:Design. Just from a design standpoint, the complete line of fittings available offers great latitude to architects and engineers when laying out the spacing, piping diagrams and wall space requirements for plumbing fixtures. These systems offer the engineer an option of designing a plumbing drainage system that is compact, yet extremely functional.

The architect is assured that the system uses a minimum of floor space, with all the necessary components included. Off-the-floor fixture supports should be designed in accordance with the requirements set forth within ASME A112.6.1-2002, Floor Affixed Supports for Off-the-Floor Plumbing Fixtures For Public Use.

Installation and Cost Savings. From an installation standpoint, off-the-floor water closet systems can be installed more economically than conventional floor-mounted systems. This comparison is particularly obvious in multi-story buildings that have batteries of water closets on each floor. The contractor is assured a simple, fast and efficient installation.

Figure 2. Installing piping for off-the-floor fixtures.

- Less sleeving. In most cases, only one sleeve is required to take care of the vertical inlet fitting at the start of the horizontal run.

- No scaffolding, ladders or similar supports are required, since all the roughing is done on the floor and not in the ceiling below (see Figure 1).

- Time is saved, since working conditions are more favorable and the installer works on the floor and not in the ceiling below (see Figure 2).

- “Dropped ceilings” are not required and ceiling space is saved because all the rough-in piping is on the floor above. This enables building ceiling height to be lower, effectively saving overall construction costs.

Figure 3. Water Closets: Types and Support Structures.

Types of Supports

Typically, there are two types of off-the-floor water closet supports: siphon jet and blowout. (See Figure 3.)The siphon jet bowl is the most common because its action is relatively silent and economical in water usage. It operates by a jet of water directed through the trap way, which quickly fills and starts the siphonic action immediately upon flushing. Its quiet action and large water surface, among other features, make it the most desirable bowl type. It is readily distinguished by four bolt holes, which receive the fixture support studs (see Figure 3).

The blowout bowl is particularly adapted for public use in airports, stadiums or plant washrooms. Its action is a driving one of high velocity. It has a large water area and an unrestricted trap way. It also is noisier than the siphon jet bowl because of its direct jet action. The blowout bowl is secured to the supports by three studs (see Figure 3).

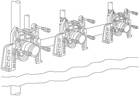

Figure 4. Battery of horizontal fittings with adjustable closet supports used in conjunction with a vertical fitting.

ADA Considerations

Industry engineers also have made sure to take into account the Americans with Disabilities Act (ADA) requirements so that the industrial, commercial and government offices are utilizing the talents of the physically impaired. Design considerations for wheelchair users must be incorporated in modern buildings. Convenient entrance and exit must be assured. Inside the building, toilet facilities for wheelchair users are priority areas for special design.Industry engineers, alert to these trends, have designed these fixture support series so that fixtures for wheelchair users can be mounted without special design by the engineer or extra work by the plumbing contractor. Installation of raised water closets using conventional supports and fittings is normally very difficult.

These designs include:

- Horizontal adjustable fittings with elevated inlet flange in left or right hand and double (back-to-back). This design permits the elevated water closet to be roughed at any position in the battery.

- Special vertical adjustable fittings with hub inlet located so that elevated water closets can be installed directly on the stack without interfering with a battery of conventional- height water closets.

- Special extra-high base supports of a strong design to accommodate the high rough fixture.

Piping Material

After determining the type of fitting and fixture support you may need for a given application, the only item needed to complete the installation would be to choose the type/material of piping you are going to use on this particular installation.Throughout our industry’s history, you could argue that the piping material most used would be cast iron. However, over time, more and more piping materials are being introduced into the industry and are viable options. Some of the many different types of piping materials used in today’s construction industry are listed below:

Acrylonitrile-butadiene-styrene (ABS)

Cast iron (CI) - This would also include Service (SV) and Extra Heavy (XH)

Ductile iron

Polyvinyl chloride (PVC)

Galvanized steel

Stainless steel

Battery of horizontal fittings with adjustable closet supports connected to a stack fitting.

Battery Length

Facility design will determine the total number of fixture supports that would be required to make up the battery length for the given application. (See Figure 4.) Over the years, due to mandated water conservation requirements lowering the flush rate to 1.6 gallons of water, battery lengths have decreased due to simple fluid mechanics. The simple fact of less flowing water per flush will not allow the waste to be distributed efficiently along the horizontal battery piping to the vertical stack fitting.Prior to water conservation issues taking effect, battery lengths could be much longer due to the allowance of at least 3.5 gallons of water per flush being available to carry the waste downstream.

Regardless of manufacturing industry changes, government-mandated water conservation requirements and engineering and architectural parameters, it’s fair to say that no matter the application and/or installation needs, there will be fixture supports available to meet even the harshest design requirements.

References

Jay R. Smith Mfg. Co. Product CatalogAmerican Society of Mechanical Engineers, A112.6.1-2002,Floor Affixed Supports for Off-the-Floor Plumbing Fixtures For Public Use.

Acknowledgments

Jay R. Smith Mfg. Co., IllustrationsCast Iron Soil Pipe Institute, Abbreviations