The American National Standard for Emergency Eyewash and Shower Equipment, ANSI Z358.1-2004, is published under the auspices of the Industrial Safety Equipment Association (ISEA). A most important requirement of the standard reads: “Medical recommendations suggest a flushing fluid at tepid temperatures to be delivered to chemically injured tissue.” “Tepid” is defined in the standard as “moderately warm; lukewarm.”

Further, water that is too warm (more than 100

Emergency mixing valve for eye-face wash. Courtesy of Guardian Equipment

Correct Application

How many of these emergency valves are really necessary for emergency fixtures? Should one emergency valve be selected for each fixture? How about one valve for every two fixtures?These are legitimate concerns, and correct application is an area where the design engineer, safety professional and owner must provide their expertise in the emergency valve selection process. Here are the steps involved:

- Slecting the emergency mixing valves, the designer, safety professional and owner must first determine how many emergency fixtures of each type will be installed.

- location of each fixture, as well as the proximity of hot and cold water supplies, should then be chosen.

- flow capacity and correct type of emergency valve must then be checked to ensure it can provide the minimum flow of tepid water for each fixture. For example, a Type “C” emergency valve will provide flow of at least 60 gpm (227 liters per minute) at 30 psi. If there are three drench showers in an area, the required minimum flow rate (according to the standard) is 20 gpm per drench shower. The designer must decide if three Type “C” emergency valves should be installed (one at each fixture) or if one Type “C” valve can be used to supply all three showers.

Loss of Hot Water Supply (Cold Water By-Pass Flow). One Type “C” emergency valve will supply adequate flow for up to three drench showers when both hot and cold supplies are functioning. But…if the hot supply is interrupted, the Type “C” emergency valve may flow only 40 gpm of cold water, enough for only two showers.

Is there a potential for a major event requiring the use of all drench showers at once? If so, one Type “C” emergency valve should be recommended for each shower. The major consideration is one of responsibility: Will there be adequate flow of water to the emergency equipment under all conditions?

Is the owner prepared to cover the expense of three Type “C” valves instead of one?<

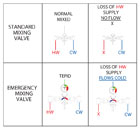

Figure 1. Performance of standard mixing valve vs. emergency mixing valve.

Correct Selection

First, make certain the thermostatic mixing valve is an emergency mixing valve designed for emergency shower and eye/face wash applications. These mixers are designed to function at “tepid” or “lukewarm” temperatures, generally considered in the 60

Figure 2. Correct vs. Incorrect Installation Locations.

Location, Location, Location

Emergency mixing valves should be installed as close to the emergency fixture as possible. Avoiding long runs or “dead legs” from the emergency valve to the shower or eyewash is critical (see Figure 2).In an emergency situation, the time required to eliminate the non-tepid water from the piping between the valve and the fixture can be extremely important.

Adequate Hot Water

Once the emergency fixtures and valves are installed, there must be adequate hot water to supply the valve or valves to ensure the required amount of tepid water is present at each emergency fixture. This requires the specification of adequate hot water heating and storage equipment and the design of hot water circulation to provide adequate hot water at each emergency valve location.

Eye-face wash fixture. Courtesy of Leonard Valve Company.

Set the Emergency Mixing Valve to the Correct Temperature

Emergency mixing valves are generally factory set and locked at 85Scheduled Operation and Maintenance

According to the standard, plumbed equipment shall be activated “weekly for a period long enough to verify proper operation and ensure that flushing fluid is available.” Common sense dictates that this requirement should apply not only to the emergency fixture but also to the emergency mixing valve. It is important to follow the maintenance instructions and schedules attached to each emergency valve, as they generally mandate periodic inspection, cleaning, and if necessary, replacement of parts.If in Doubt, Ask for Help

Manufacturers of emergency mixing valves are established companies with ample support resources. If questions arise during the selection process or after the installation is complete, contact the manufacturer. Each manufacturer has service staffs with adequate experience in the application and troubleshooting of these products specifically designed for emergency fixtures.Following these steps will help to ensure the most effective selection of emergency mixing valves to provide the necessary tepid flow for the client’s emergency fixtures.