One product making news in the laundry market is the GFX drainwater recovery system. This heat exchanger economically recovers heat from hot water that goes down the drain. Developed by a physicist funded by a Department of Energy grant, the GFX (Gravity Film Xchanger) provides energy and money savings anywhere hot water is consistently used.

The GFX is inexpensive, takes up a very limited amount of space, and it offers considerable financial benefits in coin-op laundry, commercial laundry and dry-cleaning operations.

When you consider that approximately 80% to 90% of all hot water energy goes down the drain and is wasted after it is heated and used once, it makes sense to recover even a portion of the available energy. The GFX has shown that it can recover as much as 85% of that energy, and recycle it back to preheat the incoming cold water entering a water heater.

The benefits of the GFX lie in the fact that a hot water heater does not have to use as much energy to raise the level of the pre-heated water to the temperature required. Hence, the more hot water you use, the more energy you save and the greater your overall benefits.

Commercial coin-ops quite often have irregular demand for hot water so they may need to have a ready supply to match demand. A heat exchanger like the GFX can improve the recovery rate of existing water heating systems, reducing the load on the existing system or eliminating the need for a larger water heater. Commercial laundries, on the other hand, can decrease the time between wash cycles, improving productivity by reducing the reheat time of water heating systems.

How It Works

The GFX is a simple device that utilizes proven heat transfer properties to be effective. As hot wastewater falls down a vertical section of drainpipe, it clings to the inner surface in a very thin film, taking the path of least resistance around the air inside. The heat from this film is efficiently transferred to incoming cold water circulating through the GFX via an independent circuit around the outside of the drainpipe. Incoming cold water, running in counter flow with the wastewater, is pre-heated before it enters the water heater. In that way, the water heater does not have to expend as much energy to raise the temperature of the pre-heated water to the desired temperature.The volume of hot water a water heater can deliver within a given period of time also increases because the water heater does not have to work as hard. In fact, a GFX drainwater recovery system can as much as triple the capacity of an existing electric water heating system.

The GFX is completely passive, with no moving parts or heating elements to wear out, and it features a self-cleaning design. It has no internal welds either, so there's no worry about leaks, and it installs easily in place of an existing drainpipe.

Applicable to the Commercial Laundry and Dry Cleaning Industry

In small to mid-size laundries where no heat recovery system is installed, the GFX can easily prove to be a valuable asset.

The unit is inexpensive to purchase and install, although, depending on the installation, more extensive modifications may be needed. Typically more than one GFX unit is required for a commercial application. Multiple units are needed to handle the higher quantities of wastewater at any given time. The units are manifolded together to handle the drainwater capacity.

Environmental Benefits

In addition to the financial savings the GFX provides, it also offers environmental benefits through its energy conserving operation. The U.S. Department of Energy estimates that heat energy equivalent to 2 billion gallons of oil could be recovered every year from residential sink and shower drainwater alone. Factor in other U.S. plumbing systems, like those found in commercial laundries, and that number rises to over 7 billion. And if just 6 million electric water-heating systems were enhanced by the GFX, carbon dioxide emissions would drop by more than 20 million tons per year, according to the U.S. EPA.Littleton Easy Wash Case Study

The following is a case study of an actual GFX installation in a commercial laundry.The Problem: Ed Zuk, owner of Littleton Easy Wash in Littleton, NH, decided he would like to expand the size of his laundromat operation. Under normal circumstances, that would require the purchase of a second water heater to handle the increased need for hot water. But Zuk had another idea, having heard about the GFX drainwater recovery system.

"I heard about the GFXs from a friend who installed a pair in his apartment house," said Zuk. "I figured that if the GFXs could preheat water to my existing water heater, I might be able to avoid purchasing another water heater. I've also always had a strong environmental commitment, so the idea of capturing waste energy was also very appealing to me."

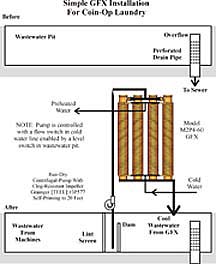

The Installation: Since there are many different basement and plumbing system configurations, every commercial GFX installation will be unique in some way. Zuk made use of a storage tank and circulators from an old "re-cycoil" system that stole heat from the dryers in his laundromat for his installation.

"I had a lint trap and a full basement that would allow gravity flow of wastewater through the GFXs," explained Zuk.

"I built a carrier for the lint trap so it was near the basement ceiling, plumbed the drains from the washers to it, and made a manifold out of PVC pipe to distribute the wastewater flow evenly to the four GFXs," Zuk said. Heated laundry wastewater flows into the 80-gallon lint trap and is filtered into the four GFXs for recovery of heat, or waste heat as it is commonly called.

"I already had the storage tank and circulator fit into the plumbing system, so I attached them to the GFXs, and added a temperature differential switch," Zuk said.

The storage tank holds the incoming cold water that has been pre-heated by the GFXs until it is ready for use. A temperature differential switch turns the circulator on when the temperature of the GFX is eight degrees warmer than the bottom of the pre-heated water storage tank. Whenever hot water is drawn off, a check valve forces the incoming cold water through the GFX to scavenge whatever heat is available. Pre-heated water stratifies in the storage tank; the warmest water comes off the top and becomes the incoming cold water for the water heater.

Zuk installed the units in June of 1999 along with some additional new washers and dryers. "It is difficult to figure out exactly how much the GFXs are saving," said Zuk. "But compared to the two months before the GFXs were installed, my business is up 17% overall. My total propane usage, however, is up only a measly 3%."

Zuk calculated that with all factors taken into consideration, his actual propane energy usage for water heating alone had dropped substantially. He estimated the units would pay for themselves in two years or less.

This article was provided by Doucette Industries. For more information on the GFX system, visit www.gfxtechnology.com.