Understanding how to read a pump curve is critical in selecting the right pump for an HVAC or water system in a commercial building. Selecting the right centrifugal pump for the facility will, in turn, maximize pump and system efficiency, and contribute to overall longer operational life.

There are different performance curves for every pump design, speed (RPM) and impeller diameter. By understanding all of the information provided by a performance curve, one can make intelligent decisions about the pump type, size, RPM, horsepower and efficiencies that will be required for the system.

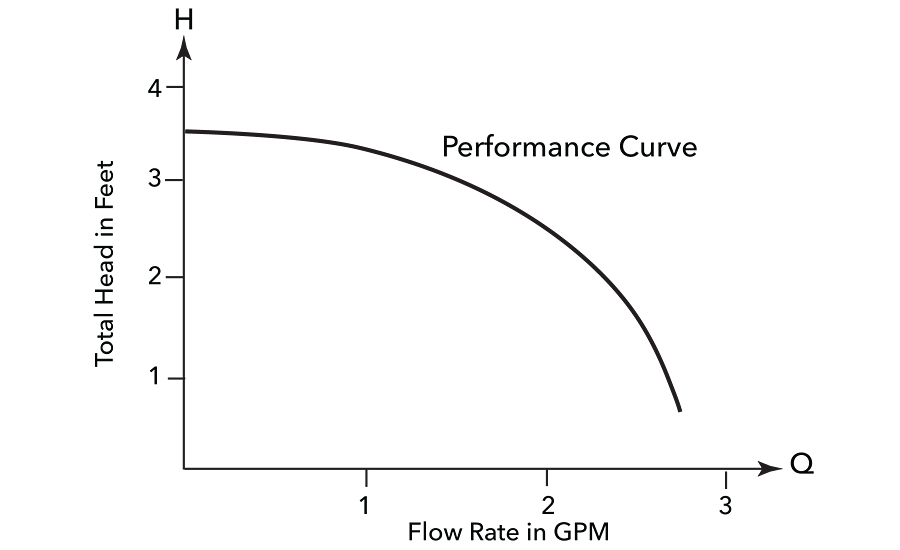

Pump curves are established by the manufacturer under carefully controlled test conditions specified by international standards. The pump curve in Figure 1 illustrates the relationship between how much flow (Q) a pump can deliver against the corresponding head (H).

Flow rates (horizontal axis) typically are measured in liters per second, gallons per minute (gpm) and cubic meters per hour. The amount of work or energy a pump can apply to a specific flow is measured in meters or feet of head (vertical axis).

Pump curves are almost always illustrated as total head in meters or feet vs. liters per second or gpm because this gives a general description of pump operation completely unaffected by water temperature or density. The gpm vs. foot-head capacity curve is general because of the physical characteristics of the centrifugal pump. The centrifugal pump produces energy in the form of foot pounds per pound of water pumped (head) and is dependent on the volume flow rate passing through the impeller. In a manner of speaking, the pump raises each pound of water passing through it to an energy level at its discharge, which is higher than that at the suction by the difference in foot head.

Energy as foot pound per pound is shortened to foot head by mathematical term cancellation. Since foot head is a simple energy statement, a pump curve defined by this term is not affected by water temperature change. This is because energy is not affected by temperature change. Likewise, water density has no effect on the pump curve, though density does affect pump power requirements.

The curved line in Figure 2 illustrates the flow/head relationship of a specific pump at a known speed and impeller diameter. It is important to note that changing the speed or impeller diameter will produce a new flow/head relationship for this pump and alter the curved line.

To read the curve, find a point on the horizontal axis, which represents gpm. In this example, the chosen point is the 2-gpm mark. Then draw a vertical line from the 2-gpm mark until it hits the pump curve. At the intersection of the 2-gpm line and the pump curve, draw a horizontal line toward the left axis to identify the corresponding head. From this, one can determine the pump will deliver 2 gpm at 2.5 ft. of head.

Similar readings can be taken from the vertical axis. If one needs to know the flow rate at 3 ft. of head, a line can be drawn from the 3-ft. mark on the vertical axis until it intersects with the pump curve. Then, draw a second line straight down to hit the horizontal axis at 1.5 gpm. Therefore, in this example, at 3 ft. of head, the pump will deliver 1.5 gpm.

The first step toward proper pump selection is to ensure the required system flow and head fall on or marginally below the pump performance curve. The remaining steps involve comparing additional information, such as horsepower, efficiency, etc., included on performance curves to help eliminate poor-performing pumps.

Horsepower on the pump curve

Now that the head capacity relationship along the X and Y axes of the pump curve has been established, the pump curve can be used to determine the amount of horsepower required to meet the head and capacity requirements for the job.

Horsepower is a unit of power equal to 550 foot-pounds per second or 746 watts. Water horsepower is the minimum power required for a pump to move water throughout a given system or the power the pump would require if it were 100% efficient.

Determining water horsepower: Shown in the chart above, when work (or head in foot-pounds per pound) is combined with the flow rate (measured in gpm), the result is the conversion for horsepower. This energy imparted to water by the pump is called water horsepower (WHP).

Water horsepower is zero at no capacity and increases with increasing flow, representing an important characteristic of the centrifugal pump — power requirements generally increase with flow even though head decreases.

Water horsepower also increases with fluid density, even though the head capacity curve is not changed. This is because at any fixed gpm point, more mass (more pounds per minute of fluid) is being pumped at the higher fluid density. If a fluid with twice the density of water was pumped, the required water horsepower would be doubled. The effect of fluid density must be taken into account when evaluating horsepower requirements for fluids other than water.

Brake horsepower: No pump can convert all its mechanical power into water power. This is due to friction losses in the bearings, water friction itself and recirculation within the pump. To compensate for those losses, horsepower going into the pump (at the pump shaft) must be greater than the water horsepower leaving the pump. These additional power losses define the total brake horsepower requirement (BHP) at the pump shaft. Brake horsepower is the actual horsepower delivered to the pump shaft. The formula for figuring brake horsepower is:

The head capacity curve will give information on the brake horsepower required to operate a pump at a given point on the curve. The brake horsepower curves run across the bottom of the head capacity curve usually sloping upward from left to right. These lines in the chart above correspond to the curves above them (the top head capacity curve corresponds to the top BHP line and so on). Comparable to the head capacity curve, there is a brake horsepower curve for each impeller trim.

In the example below, the design (or duty) point is at 120 gpm and 150 ft. of head; the corresponding brake horsepower is 6.8 BHP.

Horsepower also can be plotted as lines of constant horsepower as shown below. Horsepower is plotted across the head capacity curves as dashed lines at a downward angle. In the example below, the design point is at 375 gpm and 45 ft. of head; the corresponding brake horsepower falls between 5 and 7.5 and is about 6.5 BHP.

End of curve horsepower

When sizing the motor for any application, an important consideration is whether the pump will ever be required to operate at a flow rate higher than the design point.

If, for example, the pump was allowed to operate at the end of the head capacity curve, the actual horsepower requirement may exceed the design point selected motor horsepower and overload the motor. As previously noted, power requirements generally increase with flow, so the motor will draw more current because the pump is applying more horsepower to the fluid. For this reason, it is common practice to size the motor not for the design point, but for the end of the curve or maximum horsepower requirements.

In the example below, a 7.5 HP motor would adequately power the pump at a design point of 120 gpm at 150 ft.; however, looking at the end of the curve, brake horsepower requirements call for a 10 HP motor.

Affinity laws: It also is important to keep in mind the Affinity Laws associated with the rotational speed (RPM) and impeller diameter of a centrifugal pump. Affinity Laws are mathematic relationships that allow for the estimation of changes in pump performance as a result of a change in one of the basic pump parameters. These principles assume the operating points are at the same efficiency. If either the speed or impeller diameter of a pump changes, you can approximate the resulting performance change using the following relationships:

Note that brake horsepower varies directly as the cube of the RPM or impeller diameter ratio. If RPM or the impeller diameter of an existing pump is increased, the motor’s rated horsepower should be verified to prevent overloading.

Knowing how to determine horsepower on the head capacity curve will assist in selecting the best pump for the job or determining the pump’s performance in a specific situation. Pumps that operate at higher efficiencies will save horsepower and use less electricity, reducing operating costs.

This article was originally titled “Ahead of the curve” in the November 2016 print edition of PM Engineer.