A common misunderstanding is that automatic fire sprinkler protection is not needed in cold environments because everything is frozen and the chance of a fire occurring is viewed as minimal. However, history has shown that cold environments do burn and major losses due to fire have been recorded. Annual National Fire Protection Association (NFPA) estimates include 137 fires in freezers or cold storage areas, resulting in more than $32 million in direct property losses.

Providing automatic fire sprinkler protection in areas subject to the cold will provide an increased level of property protection, as well as reduce the risk to people who must be in these cold areas. In many cases, sprinkler protection is mandated by the jurisdiction’s building code or fire code. When sprinkler protection is installed in cold environments, additional precautions must be utilized to ensure that the sprinkler system will operate properly when needed.

NFPA 13, NFPA 13R and NFPA 13D all provide sprinkler installation requirements when a sprinkler system must be installed in or near a cold area.

In general, a sprinkler system that is normally filled with water (a wet-pipe sprinkler system) should only be used when the area can reliably be maintained above 40°F (4°C). When the piping in the area cannot reliably be maintained above 40°F, one of the following systems should be used:

- Antifreeze system;

- Dry-pipe system;

- Preaction system; or

- List dry sprinklers that are specifically listed for use in cold areas (standard dry-pendent, dry-upright or dry-sidewall sprinklers extending from a heated area).

If the temperature in the space is maintained below 32°F (0°C), NFPA 13 treats these spaces as refrigerated spaces and extra protection is required. Even if the system is not in a cold area, but instead passes through or near a cold area, NFPA 13 provides additional requirements to protect the piping from freezing.

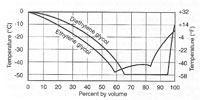

Figure 1. Increased proportions of antifreeze do not always lower the freezing point of the solution if mixed beyond the recommended percentages. Source: NFPA 13, Figure A.7.6.2.4.

Antifreeze Systems

Acceptable antifreeze solutions for sprinkler systems that are not connected to the public water supply include glycerine, diethylene glycol, ethylene glycol and propylene glycol mixed with the proper percentage of water. For sprinkler systems that are connected to the public water supply, a reduced-pressure principle backflow preventer must be installed to isolate the antifreeze system from the potable water supply. Non-metallic CPVC sprinkler systems can only use a glycerine antifreeze solution, as other antifreeze solutions may be detrimental to CPVC piping and fittings.

Antifreeze should never be used in sprinkler systems without first mixing it with water in the proper proportions. Increased proportions of antifreeze do not always lower the freezing point of the solution if mixed beyond recommended percentages (see Figure 1). Some antifreeze in 100% solutions will thicken near freezing temperatures, and some are even flammable in highly concentrated solutions.

In an antifreeze system, the antifreeze needs to provide freeze protection for temperatures below the minimum temperature in the space. The percentage of the antifreeze-water mixture must be in accordance with NFPA 13, and the specific gravity can be checked with the use of a hydrometer. A backflow preventer (as previously noted) and expansion chamber is recommended if the system is connected to a potable water supply.

Sectional drains on a dry pipe sprinkler system can reduce condensation in the system. Source: NFPA 25 Handbook.

Dry-pipe System

A dry-pipe system is a system where the water is held back by a dry-pipe valve and the system piping is filled with pressurized air or an inert gas (i.e., nitrogen). When a sprinkler in a dry-pipe system opens, the pressurized air discharges from the system, allowing the dry-pipe valve to open, releasing the water into the system.

Dry-pipe systems typically use an air compressor to fill the system with pressurized air. If the piping in the dry-pipe system is leaking, the air compressor will constantly run, introducing excessive amounts of water condensation (moisture) into the system. If this is occurring or ice accumulates in the air supply piping, the system should be checked for air leaks.

NFPA 13 requires that the dry-pipe valve and supply piping be in a heated area maintained at or above 40°F to protect the valves from freezing. If there are short exposures of the valves to temperatures below 40°F that would not allow the valves to freeze, then a heated valve room is not required. The heat source for the valve room must be permanently installed. Heat tape cannot be used as a permanent heat source for the dry-pipe valve.

Dry-pipe systems are limited in volume, unless the water can be delivered to the most remote sprinkler in 60 seconds. The air supply that is used to fill the system with air must be capable of returning the system to normal pressure in 30 minutes (or 60 minutes if the refrigerated space is held below 5°F).

Dry-pipe systems must be pitched to allow the water to drain from the system regardless of whether it is in a cold space or not. Dry-pipe branch lines must be pitched 1/2 inch per 10 feet of pipe, and dry-pipe mains must be pitched 1/4 inch per 10 feet of pipe. If the main is in a refrigerated space, it must be pitched 1/2 inch per 10 feet.

Small sections of trapped piping (less than 5 gallons) can utilize 1/2-inch auxiliary drains where water cannot drain back through the pitched piping. For trapped sections of piping larger than 5 gallons, an auxiliary drain consisting of two 1-inch valves and one 2-inch x 12-inch condensate catch pipe can be used.

Dry-type sprinkler. Source: NFPA 25 Handbook.

Preaction System

A preaction system is typically used when there is a concern with an accidental discharge of water. Similar to a dry-pipe system, the piping is normally filled with air. Smoke or heat detection devices are installed in the same space as the sprinkler system. When the smoke or heat detector activates, it allows the preaction valve to release water into the system and discharge from any open sprinklers.

The sprinklers used in a preaction system must be an upright sprinkler, a listed dry type, a horizontal sprinkler where water cannot be trapped, or a pendent or sidewall sprinkler installed on a return bend. In the last case, the sprinkler, return bend and branch line must be in a 40°F-heated space. All piping in a cold space must be pitched to drain.

Listed Dry Sprinklers

Listed dry sprinklers are attached to a wet-pipe system and extend into the cold area. Dry sprinklers have to be of a sufficient length to prevent heat loss by conduction. Factors to consider include the amount of heat in the heated space and the manufacturer’s recommended length depending on the temperature in the cold area.

Due to concerns with multiple moving parts and the possibility of ice formation on dry sprinklers, they must have a representative sample tested every 10 years or they must be replaced. The representative sample consists of four sprinklers or 1% of the sprinklers being sampled, whichever is greater.

Figure 2.Refrigerated spaces with the ability to inspect for ice plugs. Source: NFPA 13, Figure A.7.9.2.4.

Refrigerated Spaces With Temperatures Below Freezing

When sprinkler piping penetrates through the wall of a refrigerated space, there must be a 30-inch section of removable pipe to allow the system to be inspected for ice blockage. There are two required pressure gauges on the system (see Figure 2). One gauge (P2) indicates the pressure in the cold space and another gauge (P1) indicates the pressure before the air goes into the cold space. If the pressure on P1 is greater than the pressure on P2, an ice blockage has probably occurred.

The air supply for the system must use air from the room with the lowest temperature to reduce the moisture content or use an air compressor with a listed dryer package. Compressed nitrogen supplied from cylinders can be used instead of compressed air. The air or nitrogen supply piping must have two easily removable 1-inch-diameter supply lines at least 6 feet long.

Each supply line must have a control valve in a heated area. This arrangement allows one air supply line to be open at any one time. When an ice blockage occurs, one of the lines can be closed and the alternate line can be opened while the blockage is cleared. Although an air dryer is not required, it is a recommended way to improve the system’s performance by reducing condensation.

Figure 3. No insulation should be between the heated area and the sprinkler piping. Source: NFPA 13R, Figure A.5.3.2(b.)

Wet Systems Near Cold Areas

Water-filled supply pipes and system risers or feed mains that pass through or near cold areas exposed to freezing temperatures must be protected from freezing. This can be accomplished by covering the piping with insulation (see Figures 3 & 4) and allowing the heat from a heated area to keep the system warm or provide a reliable method of maintaining a minimum temperature above 40°F and below 120°F (48.9°C), such as a listed heat-tracing system.

If heat tracing is used on branch lines, it must be specifically listed for use on branch lines and the system must be supervised. Sprinkler piping that is covered by insulation is considered to be part of the area below the ceiling. In these cases, the piping is not considered part of an unheated area, such as an attic.

Figure 4. Sprinkler piping conducts heat from the heated space below the insulation. Source: NFPA 13R, Figure A.5.3.2(b).

Inspection, Testing and Maintenance

NFPA 25, Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems, must be used to ensure the sprinkler systems in the cold environments will work properly. Some of the requirements from this document include:

- Antifreeze System - Annual testing of the antifreeze solution;

- Dry-Pipe System - Annual partial-flow trip test and a 3-year full-flow trip test;

- Preaction System - Annual trip test;

- Dry Sprinkler - 10-year test of representative sprinkler sample; and

- Refrigerated Spaces - Weekly check of gauges P1 and P2.