Variable-speed injection has been used in North American hydronic systems for well over a decade. A basic schematic for this method of water temperature control is shown in Figure 1.

Figure 1

1. The injection risers are connected to the boiler loop and distribution system using a pair of closely spaced tees. This separates the dynamic pressure of the injection pump from that of the boiler loop circulator, as well as the distribution circulator.

2. The set of closely spaced tees connecting the risers to the boiler loop is at least 18 inches above the tees connecting the risers to the distribution system. This arrangement forms a thermal trap to prevent heat migration into the distribution system when the injection circulator is off.

The rate of heat flow to the distribution system is controlled by regulating the speed of the injection pump. A typical installation uses a standard AC wet-rotor circulator with a permanent split-capacitor motor. Its speed is adjusted electronically, altering the AC waveform supplied to the pump’s motor.

The small wet-rotor circulators typically used for injection mixing are often significantly oversized for the necessary flow and head requirements. This happens because the North American hydronics industry currently doesn’t offer “micropumps” specifically tailored to the minimal flow and head requirements of a typical residential injection mixing system. Thus, it’s common practice to use a standard 1/25-hp zone circulator for the injection pump. Such pumps are readily available and inexpensive.

Because the injection pump is often oversized, it’s capable of injecting all the flow needed for design load conditions while operating at a small fraction of full speed. This results in low “rangeability” and limits the injection controller’s ability to fine-tune the water temperature in the distribution system.

To compensate for these effects, a flow restrictor valve is installed in one of the injection risers to throttle away additional head and force the injection pump to operate at higher speeds. When this valve is properly set, the injection pump should run at or close to full speed under design load conditions.

Figure 2

The easiest way to set the flow restrictor valve is to have a flow-metering device installed in the return injection riser, as shown in Figure 1. I prefer to use a flow restrictor valve with a built-in flow meter, but the flow meter also could be a separate component from the flow restrictor valve. Be sure the flow restrictor valve is a “globe-type” mechanism specifically designed for throttling flow. Do not use a ball valve for this application.

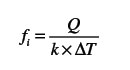

Step 1: Calculate the required injection flow rate under design load conditions using Equation 1.

fi = required injection flow rate (gpm)

Q = rate of heat transfer to distribution system (Btu/hr)

∆T = temperature difference between supply and return injection risers (ºF)

k = a constant depending on fluid used (for water, k = 490; for 30% glycol solution, k = 479; for 50% glycol solution, k = 450)

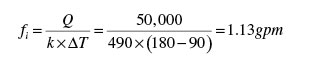

Here’s an example: A low-temperature radiant floor panel has a design output of 50,000 Btu/hr when supplied with 105°F water and operating with a 15°F temperature drop. What is the required injection flow rate of 180°F water through the two-way valve under these conditions?

Solution: The water temperature returning from the panel under these conditions is 105 - 15 = 90°F. Putting the numbers into Equation 1 yields:

Step 2: After the system is filled and purged, operate the injection pump at full speed. Also be sure the flow restrictor valve is fully open.

Step 3: Partially close the flow restrictor valve until the flow rate indicated on it matches the flow rate calculated in Step 1. Note the position of the flow restrictor valve stem for future reference in case it is moved. You’re done.

The system is now set so that the injection mixing pump will operate at full speed during calculated design load conditions. Provided that the loads and supply water temperatures do not change, the flow restrictor valve should not need further adjustment.

It is likely that special purpose “micropumps” will eventually be available in North America that would eliminate the need for “neutering” the performance of an oversized pump to attain the necessary control characteristics. Until that time, use this procedure for maximizing the accuracy of your injection mixing systems.