Pressure-assist technology has come of age. Over the past 20 years, this technology--which is based on pressure flushing technology--has been used in tank-type toilets in commercial, residential and institutional facilities. The facilities, which range from retail stores, hotels and custom homes to multi-housing units and large apartment complexes, require the performance of a low consumption fixture.

Pressure assist offers engineers diversity and durability--qualities that are in high demand in today's installations. Consider some of the most important issues related to restroom design from the building owner's perspective: maintenance, installation and water savings. From the architect's viewpoint, aesthetics might top the list of priorities. Pressure-assist technology can meet all of these requirements.

Performance

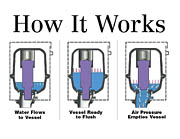

Once installed, tank-type toilets equipped with pressure-assist operating systems prove their worth with consistent one-flush performance. Prior to installation, however, plumbing engineers need a sound knowledge of how the technology works in order to convince clients of the inherent value.Flushometer tanks are a component of a complete toilet system. Like all pressure-flushing systems, the bowls are specifically designed to harness the energy of the pressure flush. This design includes hydraulics that "push" the contents out of the bowl, as opposed to gravity's siphon action (which "pulls"). Here is how flushometer tank technology works:

The flushing cycle begins as water fills by entering the supply group and then moving into the pressure vessel itself (see Figure 1). As water enters, the air trapped within the vessel is compressed to a regulated maximum of 35 psi. When this internal air pressure equals the regulated water line pressure, the water flow ceases, and the toilet is ready to be flushed. Minimum static line pressure of 20 psi is required.

The compressed air inside the pressure vessel is the core operating principle of the entire system. The water in the pressure unit becomes "pressurized" as a result of this compressed air. So, when the toilet is flushed, this stored energy delivers water from the vessel to the bowl at an extremely high flow rate. The energy "pushes" the water into the specially designed bowl. And, because the bowl uses a much simpler trapway, this pushing gives flushometer tanks their high performance capability.

Pressure-flushing technology is built around "contact points" in the design of the bowl. A contact point is where waste comes into contact with the bowl itself. These points are largely located in the trapway. The guiding principle here is the fewer contact points, the better the performance.

Pressure-assist toilets are designed to have simple trapways, with up to 5-inch diameters at critical points, thus reducing the contact points for traveling waste. Minimizing the number of contact points results in several advantages.

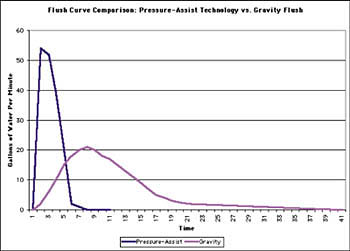

First, waste transfer rates are enhanced, clearing quickly and efficiently. Second, reliability is enhanced due to the repeatable performance. Every time the pressure-assist unit is flushed, it delivers a consistent flush curve (see Figure 2). Ultimately, this leads to a cleaner bowl and exceptional drainline carry. Finally, pressure-assist bowls are no different, as far as installation requirements, and are available in 10-, 12- and 14-inch rough-in dimensions.

Drainline Carry

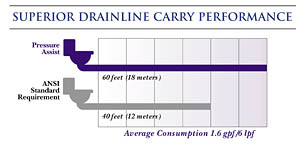

While one-flush performance may be the easiest benefit for engineers to articulate, communicating the advantages of drainline carry performance is also important. In today's plumbing environment, drainline carry is an important consideration, due to the low-consumption mandates in play.With toilet flushing (see Figure 3), moving waste downstream is a direct result of the flushing technology used by the toilet. In repeated comparisons, pressure-assist is capable of delivering superior drainline carry.

Pressure flushing discharge profiles indicate that by pushing the waste out early in the flush, more water flows after the waste, resulting in better drainline characteristics.

Aesthetics

Design is a very personal thing, and no two architects will necessarily look upon a project with the same ideas. On certain projects, however, having a tank-type toilet with the performance capability of a commercial flushometer valve is very desirable as long as vandalism is not a concern.Nursing homes, for example, have used tank-type toilets to modify their institutional appearance for years. Virtually every manufacturer of toilets carries a line of pressure-assist models for the very purpose of achieving a modern, more "homey" appearance in the bathroom.

Building owners appreciate pressure assist because the non-sweating toilet tank and the bowl's larger water surface area reduce the need for excessive cleaning. The larger water surface area can help prevent stains and ensure the bowl stays cleaner longer.

Installation and Maintenance Savings

Fixture Unit Values are important to consider during the evaluation of a project because, simply, the lower the fixture unit values, the lower the construction and installation costs. Most model codes have listings for flushometer tank water closets. Flushometer tanks are listed as half the value of flushometer valves. This is significant in that flushometer tanks can lower the fixture unit values of a project, bringing in lower project costs, because a smaller water piping and meter size can be incorporated.Where tank-type toilets are being considered, flushometer tank systems will provide the benefits of both technologies into one system. Flushometer tanks will NOT replace flushometer valves; rather, flushometer tanks offer an alternative when an application calls for such choices.

Pressure-assist operating systems also incorporate a simplified design, with fewer moving parts, to reduce maintenance. In addition, all flushometer tank systems offer a five-year warranty.

Water Conservation

It is also important to note that the low-consumption toilet effort is all about saving water without losing performance, and pressure-assist technology is one way to achieve that goal. Although the benefits of pressure assist fit commercial applications, they work equally well in residential applications.Perhaps the most important of these benefits in both commercial and residential applications is the true water savings offered through the elimination of double flushing. It has been documented, for example, that pressure assist saves up to 17% more water compared to other flushing systems.

In another example, a recent study by the City of Phoenix Water Services Department, which was based on monitoring of household water use and on customer response to a survey, found that every pressurized toilet rated in the survey was given a rating of 5, the highest rating. In addition, many other third-party endorsements, such as the NAHB evaluation of pressure-assist models, rate pressure assist as most effective for homes. Some states actually mandate the use of pressure flush for all commercial applications.

Here are more examples of where pressure-assist toilets can be used:

- Retail Stores

- Light Commercial Projects (office buildings with limited public access)

- Hotels and Motels

- Extended living (including retirement homes)

- Public Housing Projects

- Dormitories

- Religious Facilities

- Residential

Whether the project is commercial or residential, plumbing engineers who understand pressure-assist technology and can clearly explain its advantages will not only ease the restroom design process, but also satisfy clients by providing a range of long-term benefits. For major renovations and additions, the lower fixture unit values and lower static operating pressure of this technology make pressure assist an attractive option for engineers.