For decades, limited fire sprinkler tools were available to protect a wide variety of fire risks ranging from office environments to the high-challenge fires that may exist in warehouse storage facilities. For the most part, all types of fire risks during this period were protected with sprinklers having a discharge coefficient (K-factor) not exceeding a nominal 8.0 gpm/psi1/2. Starting in the 1980s and accelerating rapidly in the late 1990s to the present, a significant number of large K-factor sprinklers have been developed by the sprinkler industry that provide enhanced fire protection for storage fire risks.

The design and construction of storage facilities have changed in recent years as a result of the availability of innovative concepts and configurations used to store and distribute products. To make the most efficient use of space, products and materials are being stored higher and in closer proximity to each other, which can increase the fire challenge significantly. Many of these storage configurations create unique and formidable challenges for sprinkler systems. The availability of a variety of sprinkler-protection tools assists building owners and designers in providing economical and effective sprinkler protection for these challenging fire risks.

What are Large K-Factor Sprinklers?

The Standard for the Installation of Sprinkler Systems, NFPA 13, includes the sprinkler system design and installation criteria for many storage arrangements. The term “large K-factor sprinkler” is not specifically referenced in NFPA 13, but for the purposes of this article, the term refers to sprinklers having a K-factor of 11.2 gpm/psi1/2 or greater.The discharge coefficient, commonly referred to as the K-factor, is the rate at which water can be delivered through a sprinkler as a function of the inlet pressure. The K-factor is determined empirically by measuring the water flow rate and the water pressure at the sprinkler inlet, and then performing the following calculation:

K = Q/P1/2

Where:

K = Discharge Coefficient (K-factor) in gpm/psi1/2

Q = Flow rate in gpm

P = Inlet pressure in psi

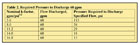

Table 1. Sprinkler Discharge Characteristics

Table 2. Required Pressure to Discharge 60 gpm

As indicated, the required pressure to discharge 60 gpm of water decreases significantly as the K-factor increases. Of course, this characteristic has economic implications for the sprinkler installation since the energy necessary to supply the required flow and pressure to the sprinkler system will be significantly less for the systems utilizing large K-factor sprinklers.

In consideration of the superior firefighting effectiveness of the large K-factor sprinkler products for storage fires, the 2002 edition of NFPA 13 was revised to require the use of sprinklers having a K-factor of 11.2 gpm/psi1/2 or larger for design densities greater than 0.34 gpm/sq. ft.

Certification Requirements For Sprinklers

NFPA 13 requires that all sprinklers be listed by an organization that is acceptable to the authority having jurisdiction. Currently, Underwriters Laboratories Inc. (UL) publishes two standards that include requirements for large K-factor sprinklers that can be used to provide protection for stored products as follows:UL 199 covers sprinklers that are intended to provide fire control, while UL 1767 covers sprinklers intended to provide fire suppression as referenced in NFPA 13. Both of these UL standards include more than 30 different performance tests to evaluate the ability of a sprinkler to perform its intended function. These tests are categorized as follows:

For sprinklers intended to protect stored commodities, large-scale tests are required by UL to evaluate the ability of the sprinkler to provide the level of protection specified in the UL listing. In 1996, UL completed construction of a 45,000-sq.-ft. fire test facility that is designed to simulate a wide range of fires that may occur in large warehouses. The primary test cell, where large-scale tests are conducted with fire sprinklers, measures almost 15,000 sq. ft.

Ceiling height and clearance from the sprinkler to the commodity can influence the effectiveness of sprinkler protection. One of the most unique features of this facility is a 100x100-foot movable ceiling that can be adjusted from heights of 6 ft. up to 48 ft. from the floor. The 10,000-sq.-ft. ceiling is much greater in square footage than the design area for sprinkler system protection, which in many cases is not more than 2,000 sq. ft.

The movable ceiling also has special features that allow for flexibility in establishing design criteria relative to sprinkler test spacing and location. To adequately supply the sprinkler system, the facility features a 200,000-gallon water supply reservoir with a pumping system capable of delivering water at a flow in excess of 6,000 gpm.

NFPA 13 categorizes materials commonly stored in storage facilities as Class I through IV and plastics as follows:

Class I. Essentially noncombustible products with or without wooden pallets placed in single-layer cardboard dividers or shrink- or paper-wrapped as a unit load.

Class II. Noncombustible products placed in slatted wood crates, solid wood boxes or multiple-layered corrugated carton with or without pallets.

Class III. Products constructed of wood, paper, natural fibers or Group C plastics, with or without corrugated cartons, wood boxes, wood crates or pallets. A Class III commodity also can contain a limited amount (5% or less by weight or volume) of Group A or B plastics.

Class IV. These are Class I, II or III products that contain an appreciable amount of Group A plastics (5% to 15% by weight or 5% to 25% by volume) within the product itself or its packaging, with or without pallets. Class IV commodities also can contain Group B plastics or free-flowing Group A plastics. Only wood or metal pallets are assumed to be used for each class of commodity.

Figure 1. Standard Class II commodity with a portion of the corner removed to illustrate the commodity construction. All photos courtesy of Underwriters Laboratories Inc.

Figure 2. Standard cartoned Group A plastic commodity with a portion of the exterior carton removed to illustrate the storage arrangement of polystyrene cups.

For example, tests to investigate the ability of the sprinkler to control a Class II commodity are conducted using double tri-wall corrugated cardboard cartons with five-sided steel (open bottom) stiffeners inserted for stability, which are placed on a hardwood pallet. The two cartons have a combined nominal thickness of 1 inch and the nominal measurements for the outside carton are 42x42x42 inches, which provides for a substantial fuel load for testing purposes. SeeFigure 1for an illustration of the Class II commodity.

Figure 3. Fire growth approximately one minute after ignition for standard, cartoned Group A plastic commodity placed on racks.

Table 3. Large K-factor Sprinkler Types

Large K-Factor Sprinklers and End Use Applications

Currently, there are 16 different types of large K-factor sprinklers that are available to provide protection against storage fires. Most of these products have been developed within the last 10 years. A list of the large K-factor sprinklers that are currently referenced in NFPA 13 or listed for this use is described inTable 3. Some of these products are produced by only one manufacturer and some are manufactured by multiple companies. The reference to “Density/Area” indicates that the sprinkler is intended to be used in accordance with the “Density/Area” design criteria specified in NFPA 13. For the Large Drop, Specific Application and ESFR sprinklers, the applicable design information is described in NFPA 13. Except for extended coverage sprinklers, the maximum protection area for each sprinkler is 100 sq. ft. Extended coverage sprinklers have been investigated for protection areas up to and including 196 sq. ft.

Figure 4. Fire involving rubber tires stored on-tread in portable racks.

In addition to protecting the previously described commodities, several large K-factor sprinklers have been subjected to large-scale tests to evaluate their ability to control or suppress other high-risk fire hazards. Other applications referenced in NFPA 13 include the storage of rubber tires and paper rolls. SeeFigure 4for a photograph of a fire test involving rubber tires.

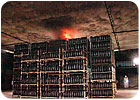

Several of these sprinklers also are suitable for protecting flammable liquid storage as described in the Flammable and Combustible Liquids Code (NFPA 30), as well as the storage of aerosols described in the Code for the Manufacture and Storage of Aerosol Products (NFPA 30B). SeeFigure 5for a photograph of a fire involving combustible liquids.

Information regarding the UL listing of these products can be obtained by visiting UL’s Online Certifications Directory atwww.ul.com. After entering the Online Certifications Directory, the two UL category codes that can be used to search for these products are “VNIV” and “VNWH.”

Figure 5. Fire after the sprinklers have operated and are discharging water onto cartoned, combustible liquids stored on double-row racks.

Summary

While this article has focused on large K-factor sprinklers used for storage protection, this technology is currently being applied to extend the sprinkler coverage areas for Light and Ordinary Hazard Occupancies as well. Each of these sprinklers has unique use and installation requirements. These products have been designed with the intent of economizing the installation of sprinkler protection, while at the same time achieving the desired fire protection objectives. In fact, large K-factor sprinklers have demonstrated during large-scale tests to be more effective than the smaller K-factor technology previously utilized. It is anticipated that more of these sprinkler tools will become available over time to meet the needs of the market.Since sprinkler systems are one of the most effective tools available to provide protection for a variety of storage fire risks, it is important for individuals associated with the fire safety community to be knowledgeable about and understand the unique application, use and limitations associated with each of these products. Detailed information is available in the applicable NFPA standard and the manufacturer’s installation and use instructions, which are a part of the UL listing.