A fire protection engineer designing sprinklers for a storage/distribution or "big box"

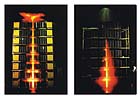

Figure 1. Rack storage tests of unexpanded plastics.

Historical Perspective1

First, a bit of history is in order to set the stage for more recent developments in sprinkler technology. Control Mode Density Area (CMDA) sprinkler protection is the oldest and still most commonly used sprinkler technology for the protection of storage. This protection is specified in the various curves in NFPA 13. It was developed in the late 1960s in response to a serious problem: large warehouse fires resulting from rapid changes in storage technology. A major full-scale fire test program was undertaken, with the goal of determining how to protect new storage arrangements (such as rack storage) with the sprinkler technology already in place in existing warehouses. As the existing technology called for K5.6 and K8.0 spray sprinklers installed on pipe schedule systems, the expectations were modest. Recognizing that existing pipe schedule systems came in a wide variety of layouts with a wide range of water supplies, the suitable protection options were presented in the form of discharge density/operating area curves. Large fires (with sprinkler operating areas up to 5,000 ft. and more) were considered acceptable, as long as the building occupants could escape safely and the building itself could be saved. Large amounts of fire, smoke and water damage were considered acceptable.

A collection of various storage sprinklers.

Storage Protection Developments in the 1970s and 1980s

Large-Drop Control Mode Specific Application (CMSA) SprinklersThe first sprinkler developed specifically for the protection of storage was the large-drop sprinkler, which was developed in the 1970s and was a K11.2 sprinkler with a deflector designed to produce a higher proportion of large water drops, enhancing penetration and performance. Designs requiring as few as 15 sprinklers were achieved, even with a substantial added safety factor. In actual tests2, there were a number of cases where fewer than 10 sprinklers controlled fires in challenging storages. As an outcome of the development of this sprinkler, experts recognized that, for high-challenge storage occupancies, sprinkler orifice size and operating pressure were the measure of sprinkler performance, not discharge density and operating area.

The perceived advantage of large-drop sprinklers was that they permitted protection of rack storage without in-rack sprinklers, which wasn't possible with spray sprinklers. Less obvious, but no less real, advantages include the ability to reduce fire and nonthermal damage, and protect higher challenge storage occupancies as compared to spray sprinklers.

Early Suppression Fast Response Suppression Mode (SM) Sprinklers

The next milestone in the protection of storage came in the late 1980s with the development of the Early Suppression Fast Response (ESFR) sprinkler by Factory Mutual Research. SM technology was driven by the demand for a means to protect higher rack storage of higher challenge commodities without the need for in-rack sprinklers and their associated costs and susceptibility to mechanical damage. Along with the enhanced capabilities of ESFR sprinklers came a new, much more stringent set of application and installation requirements. While the elimination of in-rack sprinklers was easily and widely grasped by users and designers alike, the more stringent requirements were often overlooked, creating problems that still plague the industry today.

In full-scale testing at Factory Mutual Research, Tyco's Ultra K17 sprinkler was able to protect rack storage of a cartoned plastic commodity without the need for in-rack sprinklers.

Recent Sprinkler Technology Developments

Up to the early 1990s, most significant changes in fundamental sprinkler technology applicable to the protection of storage were driven by Factory Mutual Research, which developed the standard spray sprinkler in the 1950s, as well as the large-drop and the ESFR sprinklers. Their efforts were in response to the needs of their insured clients, which were primarily large industrial operations. Then, the sprinkler industry, led by the Central Sprinkler Co. (now Tyco Fire Products), began its own development efforts in response to its own customers' needs.Extra-Large Orifice (ELO) CMDA Sprinklers

The ELO Sprinkler began life as the Central D64. It was intended to be simply a K11.2 sprinkler that allowed the design of higher densities at lower pressures, purely for economic reasons. But its performance in storage fires was still unverified as compared to the K5.6 and K8.0 sprinklers used in the test on which the density/area protection guidelines in NFPA 13 were based. In the early 1990s, a full-scale test program3was undertaken to validate its performance. In this program, benchmark scenarios from the original storage test programs were repeated, with the only change being the substitution of the ELO sprinkler producing the same density at a correspondingly lower pressure.

In these tests, the ELO sprinkler not only performed as well as the older types of sprinklers, but in all but one test, it performed significantly better. In a test at a minimum pressure of 50 kPa (7 psi) against a relatively high challenge storage scenario, its performance was comparable to the original test, but not superior. There is, therefore, virtually no practical reason for using K8.0 or smaller sprinklers in designing new storage protection-a fact recognized in NFPA 13 by the requirement that K11.2 or larger sprinklers be used for densities of 14 mm/min (0.34 gpm/ft2) or higher.

Larger Orifice CMDA Sprinklers

The Central Sprinkler Co. developed the K17-231 sprinkler as a further extension of the ELO concept. In full-scale tests at Factory Mutual Research4, this sprinkler also demonstrated equivalent (and typically better) performance than K5.6 and K8.0 CMDA sprinklers at densities down to 18 mm/min (0.45 gpm/ft2) [which corresponds to the 50 kPa (7 psi) minimum operating pressure].

Larger Orifice CMSA Sprinklers

The Central Sprinkler Co. developed the Ultra K17 sprinkler in order to achieve performance comparable to large-drop sprinklers at lower required pressures. In full-scale testing at Factory Mutual Research5, this sprinkler was able to protect rack storage of a cartoned plastic commodity without the need for in-rack sprinklers.

The Ultra K17 sprinkler has not been tested in all of the applications that the large-drop sprinkler has and cannot be used as an across-the-board replacement. Before it is used in a design, the engineer should verify that it is approved/listed for the intended application.

Larger Orifice Pendent SM Sprinklers

The original K14 ESFR sprinkler very often creates design difficulties due to the demand for high pressures, so the Central Sprinkler Co. developed a K25.2 suppression mode sprinkler at Factory Mutual Research. The sprinkler proved effective in development testing6, but required higher discharge flows (though still at lower pressures) than the K14 ESFR to meet FM approval requirements. Subsequent testing at Underwriters Laboratories7produced results equivalent to the K14 ESFR at the same discharge flow, allowing even lower design pressures.

More recent testing has shown that the K25 suppression mode sprinkler can protect some challenges greater than the K14 ESFR could handle. For example, it can protect solid-piled/palletized storage of uncartoned expanded plastics up to 7.6 m (25 ft.) high in buildings up to 12 m (40 ft.) high. It also can protect rack storage of unexpanded plastics in buildings up to 26 m (45 ft.) high (Figure 1).8

Following the introduction of the K25.2 suppression mode sprinkler, Tyco Fire Products' K16.8 and Reliable Automatic Sprinkler Co.'s K22.4 versions were developed. Again, the driving force behind their development was to reduce the required operating pressure. Testing of the K16.8 suppression mode sprinkler has shown it to be essentially equal in performance to the K14 ESFR.9To date, there has only been limited full-scale testing of the K22.4 suppression mode sprinkler, and while it may have potential uses on higher challenge fires like the K25.2 suppression mode sprinkler, none have been identified as yet.

Extreme care must be taken when selecting a particular suppression mode sprinkler to assure that it is approved/listed for the intended application. The various suppression-mode sprinkler models are not interchangeable, and each has its own application and installation requirements. At this time, the pendent K14.0 ESFR has the widest range of application, followed by the pendent K16.8 suppression mode sprinkler. The pendent K25.2 suppression mode sprinkler has almost as wide a range of applications and can protect some storage configurations in 26-m (45-ft.) high buildings that the K14.0 ESFR can't. The pendent K22.4 suppression mode sprinkler has a narrower range of applications.

Upright Larger Orifice Suppression Mode Sprinklers

The limitation on clearance created installation difficulties. In response to this, the Viking Sprinkler Corp. extended their K11.2 upright SM sprinkler to a K14 model via testing at Factory Mutual Research. Although limited as to the commodities and building heights it can protect (due to the reduction in discharge momentum resulting from the upright orientation), it has the advantage of being less sensitive to small obstructions. Typically, locations with respect to the bottom chords of bar joists, individual pipes and conduits, etc., are generally not a concern.

More recently, a K16.8 upright suppression mode sprinkler was developed by Tyco Fire Products. This sprinkler offers benefits (and limitations) similar to the K14 upright, with the added advantage of lower pressure requirements.

Again, extreme care must be taken when selecting an upright suppression mode sprinkler. In particular, currently available models are limited to use in buildings no more than 11 m (35 ft.) high.

K25 Extended Coverage (EC) CMDA Sprinklers

In an effort to address storage occupancies that could not be practically protected by suppression mode sprinklers, as well as to reduce installation costs, Tyco Fire Products developed a K25.2 CMDA sprinkler that could be installed with a coverage area up to 19 m2(196 ft2) and spacing up to 4 m (14 ft.). This is a significant increase from the previous limits of 9 m2(100 ft2) and 3.7 m (12 ft.).

The sprinkler underwent a series of full-scale fire tests10 similar to those for the ELO sprinkler, and like the ELO, demonstrated superior performance. One particular benefit is the sprinkler's resistance to "skipping"

With more than 20 years of experience in the fire protection industry, James E. Golinveaux is the senior vice president of Research and Development for Tyco Fire & Building Products. Golinveaux also contributes his time as a speaker for universities, state and local fire authorities and trade associations. He has authored numerous technical and white papers, contributing to the "NFPA Fire Protection Handbook 19th Edition,"