Point: Pressure Assist

By R. Bruce Martin

Issue: 11/03Because water supplies had always been thought of as limitless, until the 1970s, almost all water closet designers only concerned themselves with style. This, combined with unrealistically low user cost, resulted in no incentive to conserve water. Back then, the common w.c. consumed between five and eight gallons per flush (gpf). In 1972, the typical single-family house consumed about 1,300 cubic-feet of water monthly. The cost to the homeowner (water and sewer combined) amounted to only about $87 a year.

Starting around the mid-'70s, as market demand started to significantly exceed supply resources and waste treatment capacity, the situation started to change. Bureaucrats were no longer able to delay adding new resources and/or treatment capacity. While much of the funding came from the sale of municipal and state bonds, water and sewer rates (W&S) also started to skyrocket. For example, between 1972 and 1983, the annual cost of W&S to the "typical" single-family dwelling unit(1) rose from $87 to $170 (+28% per year). By 1994, this had increased to $317, and by 2001, to just under $630--better than a 25% average annual increase over the 29-year period.

Responding in the early 1980s to building moratoriums that had become common throughout the Eastern U.S. due to inadequate waste treatment capacity, American Standard introduced the first water conserving water closet--the Water Saver Cadet(TM)--a two-piece combo that consumed 3-1/2 gpf. Because of its severe W&S capacity shortfall, the Washington Suburban Sanitary Commission (WSSC) used that product as basis for mandating that no toilet could be installed within its jurisdiction that consumed more than 3-1/2 gpf. This set off a competitive stampede by manufacturers. Many simply converted their 5-1/2 gpf w.c.'s to 3-1/2 gpf by reducing the size or blocking off or partitioning part of the vitreous tank reservoir. Because they were designed to build siphon using 5+ gallons, these new hybrid combinations performed poorly. The market backlash did, however, cause a reawakening of hydraulic research at most fixture manufacturers.

The first pressure-assist water closet was introduced in 1984. The Flushmate®-powered Quantum(TM) from Mansfield shook up the industry because it used only 1-1/2 gpf and yet equaled the extraction capability of the old 5-1/2 gpf w.c.'s. Responding to this challenge, most manufacturers began introducing 1.6 gpf gravity-activated w.c.'s, and water- and/or waste treatment-starved states started mandating their usage. Multiple variations of state laws eventually led the federal Government in 1992 to take charge by passing legislation that mandated nationally, beginning January 1994, that no toilet could be manufactured for domestic use, sold and/or installed that consumed more than 1.6 gpf. In 1997, this Federal Energy Act was extended to the commercial toilet market.

Like their gravity 3-1/2 gpf predecessors, these new 1.6 gpf gravity-activated toilets also performed terribly. Using gravity activation and historic hydraulic designs, 1.6 gallons was simply insufficient volume to establish decent extraction, let alone meet the ANSI 40-foot(2) drainline carry test requirement. Designers were faced with a dilemma:

- Reduced water-spots, bowl storage volume and trapway diameters make bowls easier to flush and improve discharge thrust for drainline carry, but increase double flush and clogging.

- Larger water-spots, bowl storage volume and trapway diameters decrease discharge thrust and make it more difficult, if not impossible, to meet the minimum drainline carry requirement.

As might be expected, consumer dissatisfaction led to a surge in demand for pressure-assisted w.c.'s. In 1997, seizing on this popularity, the PF/2® flush system, developed by Masco's W/C Technology Corp. was introduced by Eljer Plumbingware in its Aquasaver w.c. This second generation pressure-assisted flushing device incorporated improved flush power along with a smaller vessel, softer trip lever and quieter discharge.

Compared to the models offered in the late 1980s, the combination of improved bowl extraction performance coupled with lowered consumer performance expectation has resulted in gravity-activated designs now being considered generally acceptable for light demand applications--such as in single family housing. However, because toilet abuse increases in direct proportion to the distance between owner and user--in other words, people take far better care of their own toilets as opposed to w.c.'s owned and maintained by others--marginal extraction becomes increasingly less tolerable in more demanding installations such as lodging, light commercial, etc.

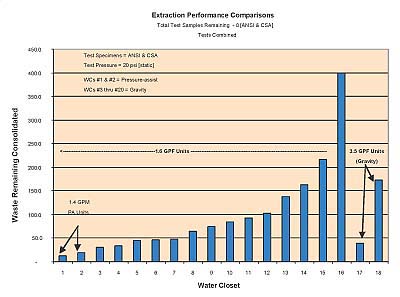

Today, wide w.c. performance disparity exists among models. Figure 1 is an extraction summary of 18 w.c.'s currently sold in the United States. Closets #1 and #2 are pressure-assist. Closets #3 thru #16 are 1.6 gravity-activated.

Less than historically acceptable performance has had both positive and negative results.

On the positive side, a couple of manufacturers have introduced innovative bowl designs that incorporate larger diameter (3" vs. 2") flush valves. These larger flush valves allow water into the bowl's trapway more quickly, thus increasing the peak discharge (gpm) flow rate. The net effect is a higher velocity, shorter duration discharge, which gives improved extraction performance.

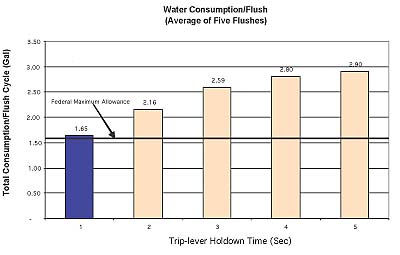

My experience is that a "typical" user depresses the trip lever long enough to be certain that the flush action is activated. Thus, it seems realistic to argue that a 2-3 sec. depression is common, and that more flush water means better extraction and happier users. With this in mind, one has to ask, "Are these trip lever designs an intentional way to circumvent federal law?"

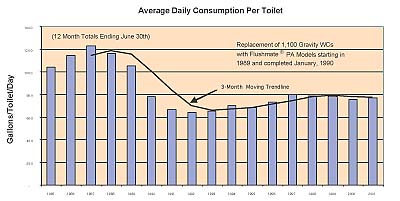

Another complaint often heard against PA toilets is that they cost too much. Prices recently obtained at "big-box" retailers indicate that pressure-assist toilets (PA's) sell for only about $70 more than two-piece gravity units offered by major brands. However, as shown in Figure 3, higher consumption is costly. PA toilets rarely require second flushes and don't develop imperceptible leaks over time. Thus, because of the lower operating cost, the initial cost differential can be recaptured quite quickly.

More disturbing is the fact that gravity flush valve flappers tend to develop (usually imperceptive) leaks after just a couple of years of service, like a faucet dripping silently 24 hours per day. Several recent studies have shown the vulnerability of gravity flappers to both age-related, imperceptible leakage and/or excessive consumption due to improper replacement. Thus, the real consumption per flush over time can be significantly greater than 1.6 gpf.

The bottom line is that careful selection can give the buyer the best of both worlds. Both technologies have their place in America. Gravity-activated w.c.'s, which are generally less expensive than pressure-assist types, serve single family consumers well. Because abuse increases in direct proportion to the distance between owner and user, pressure-assist types serve multiple-housing, lodging and light commercial best.

Bruce Martin is the inventor of the pressure-assist technology. He developed both the Flushmate® flushometer tank (sold to Sloan Valve Company in 1986) and the PF/2® pressure-flush system (sold to Geberit's Chicago Faucets Company in late 2002). Martin, who retired at the end of last year, currently acts as a consultant to Chicago Faucets Company.

Footnotes

1 Based on W&S surveys conducted for W/C Technology. Average of residential rates in effect in the 24 largest U.S. cities for 1,300 cubic feet of water usage per month.2 Forty feet represented 67% of the performance obtained by typical 5-1/2 gpf w.c.'s.

3 Similar results are obtained on many toilets incorporating a 2-inch flush valve. The only difference is that the trip lever must be held open for another second.

Counterpoint: Gravity Activation

By Fernando Fernandez

The 1.6 gpf gravity toilet's history began in Sweden. Due to geological terrain similar to that of United States north of the great glacial moraine, sewage from cities and towns was polluting their valued waterways. Well before the 1970s, composting toilets in vacation homes, and city and suburban homes' 6-liter toilets became the norm. In 1972, Sweden passed a maximum 6-liter per flush code (20 years before our 1992 EPACT amendment). Swedish manufacturers Ifo Sanitar and Gustafsberg produced numerous models of toilets that consumed from 4 to 6 liters per flush and worked well. They were all gravity powered.In the mid-'70s, Swedish toilets appeared on the U.S. market. In unmetered cities with tax supported water and sewer utilities, there was little interest. However, in rural America--where wells and septic systems were common--homeowners quickly discovered that a dramatic reduction in water use prevented wells from going dry and enabled leach fields to keep up with the absorption.

During the '70s and early '80s, valuable research was done both at Penn State University and at North Carolina State University showing that simply reducing water use eliminated supply problems, and more importantly, abated septic failure.

Not surprising, Boston, New York, Los Angeles and other cities soon recognized the ultra-low flow gravity toilet's success in the rural microcosm and applied this flow reduction solution. The Massachusetts Water Resources Authority (MWRA), the autonomous federal authority established when Eastern Massachusetts cities failed to remedy EPA violations, had the vision to mandate low consumption fixtures. In 1987, Massachusetts became the first state to pass a 1.6 gpf code (effective in 1989) and gave domestic manufacturers two years in which to comply. Sufficient Swedish inventory gave the Massachusetts plumbing board confidence that demand would be met.

Some major U.S. manufacturers failed to heed this warning. When the code became effective, however, there were successful installations from the limited products available. Manufacturers, without approved product, warned of catastrophic drain line problems that would occur if the code were enforced. Opponents had a feeding frenzy, but their fears of widespread sewer blockage never materialized.

Despite installation of hastily designed, poorer performing early models, over a million 1.6 gpf gravity toilets were installed in New York City during the celebrated $240 rebate program--the success of the program was beyond expectation. In fact, the NY DEC reported an average 37% savings in multi-family buildings that had been retrofitted. Recipients commented that their new 1.6 toilets performed better than the old guzzlers. Virtually all of these toilets were gravity powered since pressure-assisted models were too expensive to be covered by the rebate.

Gravity Toilets

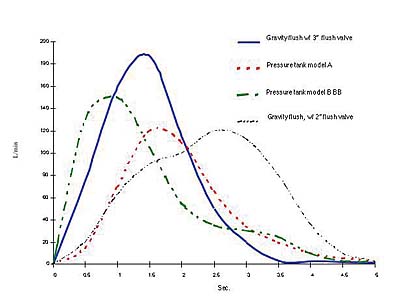

While there have been improvements in pressure-assisted flush toilets, there have been even more advances in gravity designs. The industry has taken a "ground up" approach in which both bowl and tank are engineered to meet the demand for increased extraction performance. This has been achieved by employing computer solid modeling and fluid flow analysis software to maximize hydraulic performance. Careful attention to the intricacies of the manufacturing process, coupled with enhanced, in-house testing protocols, fortify the gravity toilet's currently favored position with respect to customer satisfaction.Unlike a pressure-assisted w.c., where the flushing action represents a concentrated push through an orifice (the "jet") and the bowl designs remain homogeneous, the vast majority of gravity w.c.'s in North America utilize a pulling action, the result of simple siphonic action. Trapway designs in gravity bowls have come a long way. Smoother, curvilinear shapes have helped reduce frictional losses and eliminated the formation of air pockets during the siphon action by creating a laminar type flow. Furthermore, some trapways employ a bend in the trap (just upstream of the outlet) to strengthen the siphoning effect with an additional pocket of water or "wetted perimeter."

Many gravity water closets are capable of rivaling a pressure-assisted w.c.'s performance, and in most instances, can exceed it as water pressure drops. There followed the introduction of the 3" flush valve in gravity tanks, allowing for increased tank-to-bowl flow rate delivery. This increase in flow rate drives the flushing action, thereby matching the flow rates found in pressure-assisted models (Figure 1). Also, certain non-siphonic, gravity bowls have trapways with larger diameters than those of pressure-assisted bowls.

It is important to note that in comparing the data in the graph in Figure 1, the flow rates were measured taking into account the frictional losses as water enters and exits the bowl tramway. Measuring data only at the tank outlet is a misrepresentation of the toilet performance. Furthermore, suggestions that trip levers on gravity flush toilets are designed to be held down as an intentional way to circumvent federal law are untrue. In fact, trip lever designs are intended allow for a complete flush when the handle is completely depressed. Current activity at the standards committee level has taken this concern into account and included the maximum tank capacity criterion in the appendix of the forthcoming ASME A112.19.2M standard.

Pressure-Assisted Toilets

While gravity toilets can operate as low as 10 psi (at which a typical ballcock or pilot-operated fill valve closes), pressure-assist models require at least 20 to 30 psi at the toilet (Figure 2). Thus, the water pressure to the building must be carefully calibrated to obtain correct fit.In addition, even when operating at optimum pressures, some pressure-assisted toilets will exhibit shredding at random. Due to the high velocity of the air-forced water jet directed into the bowl, the water's penetration through paper and solids causes them to shred, breaking down into smaller pieces and scattering around in the bowl during the flush cycle. Left behind, these small bits of matter necessitate the proverbial "second flush."

Here is a summary of some of the shortcomings of current pressure-assisted toilets:

- Noisier flush than gravity toilets;

- Requires at least 20-30 psi static to flush properly;

- Requires expensive and specialized maintenance or repairs;

- High velocity trap jet may shred paper and waste, often requiring a second flush;

- Typical two-piece construction may be less aesthetically pleasing; and

- Trip lever activation typically requires more force than gravity toilets.

Certainly, there is always room for improvement, and just as gravity toilets have been improving, expect to see the same in pressure-assisted models.

Third Party Reports and Surveys

Independent reports and surveys provide more evidence of the performance of both types of toilets.Recently, at the Stevens Institute of Technology (Hoboken, NJ), the Building Technology Research Laboratory conducted a series of tests on several popular pressure-assisted models, a popular 3.5 gpf toilet, and one gravity toilet with a 3" flush valve. The report concluded as follows:

"The results of these tests enable us to conclude [that] the functional performance of the gravity driven...water closet is equivalent to that of popular pressurized flush toilets and nearly the equivalent of the traditional 13.2 lpf/3.5 gpf water closets."(1)

In addition, performance comparison testing done by independent laboratories for several major municipalities(2) during the past year do not reveal gravity toilets at one end of the performance spectrum and pressure-assisted toilets at the other. Instead, there are members of both groups scattered throughout. Consumers and specifiers need to study performance-testing results and not rely solely on manufacturer claims.

Summary

An assertion that all gravity flush models are the same or that none can hold their own against pressure-assisted models is unfounded. In an effort to exceed consumer expectations, gravity toilet manufacturers continue to re-engineer their products so that they stay ahead of the flushing curve. Some have even applied much higher levels of technology to achieve better performance than has ever been used in this industry.One is no longer safe in assuming that "a toilet is a toilet." While there were problem toilets resulting from the hasty development of products after EPACT 92, all models have improved, and the race to perfect the low consumption toilet has spawned some excellent products, many that perform more effectively than the water guzzling models of 15 years ago. There is no one water delivery or flushing system that classifies the "better flushers" into an elite group.

Below are some generalizations about modern gravity and pressure-assisted toilets that all consumers should consider:

- Higher flow rates from tank to bowl increase waste removal capability.

- Higher velocity water increases noise and can shred waste.

- Drain line carry performance improves with higher flow rates.

- Tramways with sharp bends are more likely to be blocked.

- Simpler tank mechanisms are easier to service when needed.

- Flow rates should be evaluated at bowl outlet rather than at the tank outlet.

Consumers will continue to demand better product, driving enhancements in both models, and the flushing technology saga will continue.

Fernando Fernandez is senior engineering manager for TOTO USA, Inc. He can be contacted at 1155 Southern Rd., Morrow, GA 30260, ph. (770) 282-8686, fax (770) 282-8701. For more information, visit TOTO online at www.totousa.com.

References

1A Comparative Evaluation of Competing Water Closets, Report Number R-496, prepared by Stevens Institute of Technology, Jul. 1997.2 Water Closet Performance Testing, prepared for Seattle Public Utilities and East Bay Municipal Utility District, Sept. 2002; Maximum Performance Testing of Popular Toilet Models (An Interim Report): A Cooperative North American Project Sponsored by U.S. and Canadian Partners, by William Gauley, P.E., Veritec Consulting, Inc., Mississauga, ON, and John Koeller, P.E., Koeller and Co., Yorba Linda, CA, 2003; and Ultra-Low-Flush Toilets Customer Satisfaction Survey, prepared by the Metropolitan Water District of Southern California, Dec. 1999.